Ultrasonic atomization device controlled by gyroscope

An atomizing device and ultrasonic technology, which are applied in the direction of atomizers for treatment, medical devices, inhalers, etc., can solve the problem of affecting the normal atomization processing of the ultrasonic atomizing mechanism, unable to flow into the ultrasonic atomizing mechanism, and electronic cigarette smoking. Can not inhale smoke and other problems, to achieve the effect of eliminating liquid leakage, simple structure and smooth output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

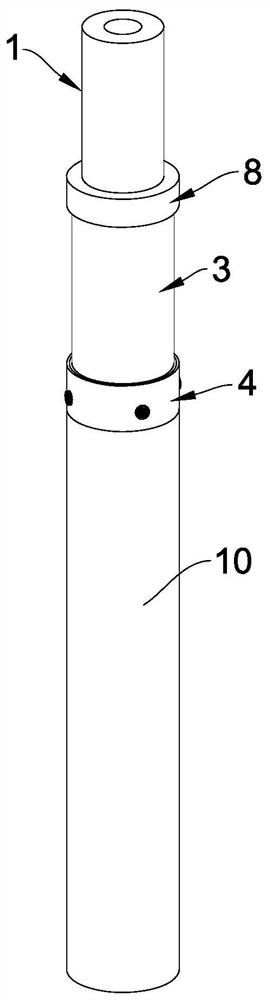

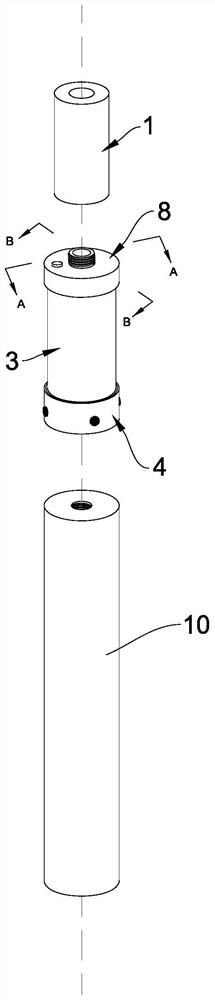

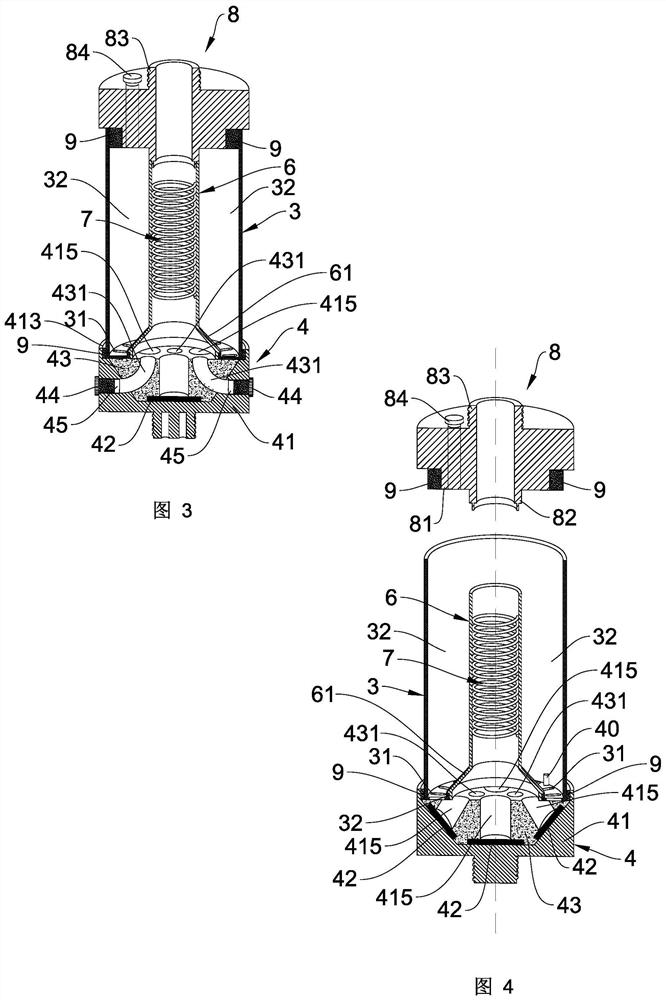

[0018] Such as Figure 1 to Figure 9 As shown, an ultrasonic atomization device controlled by a gyroscope according to the present invention includes a breathing part 1, a power supply part 2, a container part 3, an ultrasonic atomization mechanism 4, a circuit board 5, an air duct 6, an electric heating Component 7 and other main components. In order to realize the purpose that the present invention proposes, as Figure 5 As shown, the ultrasonic atomization mechanism 4 includes an atomization base 41, an ultrasonic atomization electrical chip 42, an oil storage cotton body 43, and a filter plug 44, wherein the atomization base 41 is provided with a flat-bottomed conical cavity 411, An ultrasonic atomizing electrical chip 42 is installed on the bottom surface of the flat-bottomed conical cavity 411 , and a plurality of ultrasonic atomizing electrical chips 42 are respectively installed on the walls of the conical cavity around the flat-bottomed conical cavity 411 . The numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com