Mounting process of automobile taillight

An installation process and a technology of automobile taillights, which are applied in the direction of motor vehicles, road vehicles, and signaling devices, can solve the problems of limited shape, increased car body load, and heavy weight of lights, and achieve smooth output, less low-order harmonics, and The effect of resizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1. A kind of installation process of automobile tail light

[0030] This embodiment is used to describe the installation process of automobile tail lights, and the specific installation process is as follows:

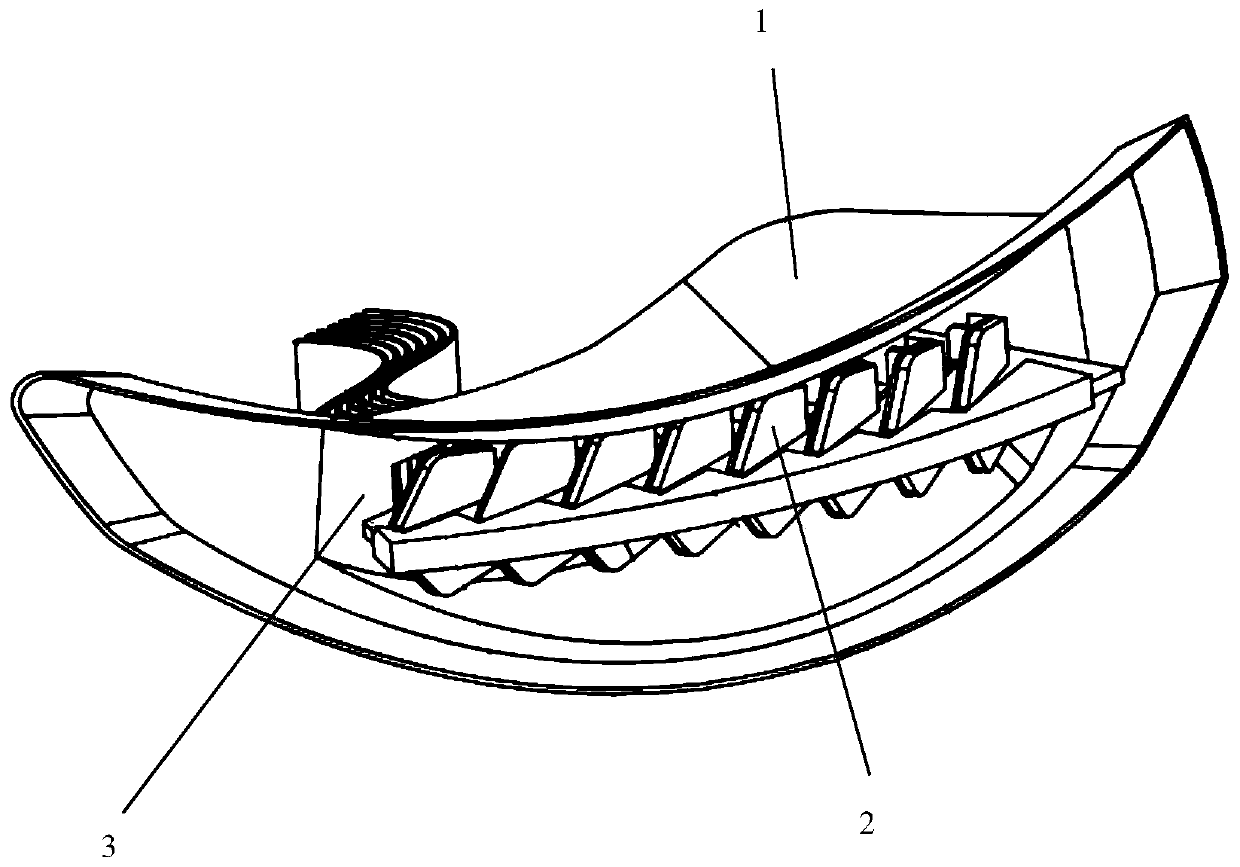

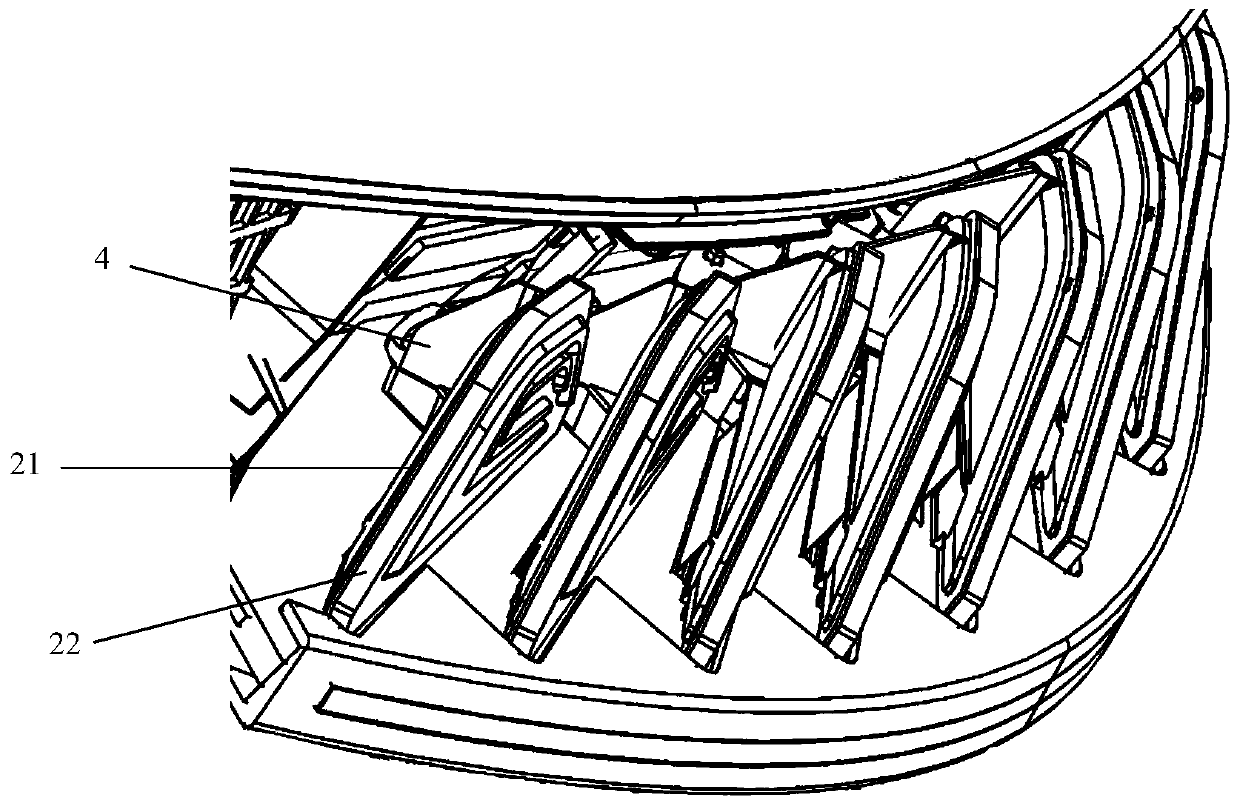

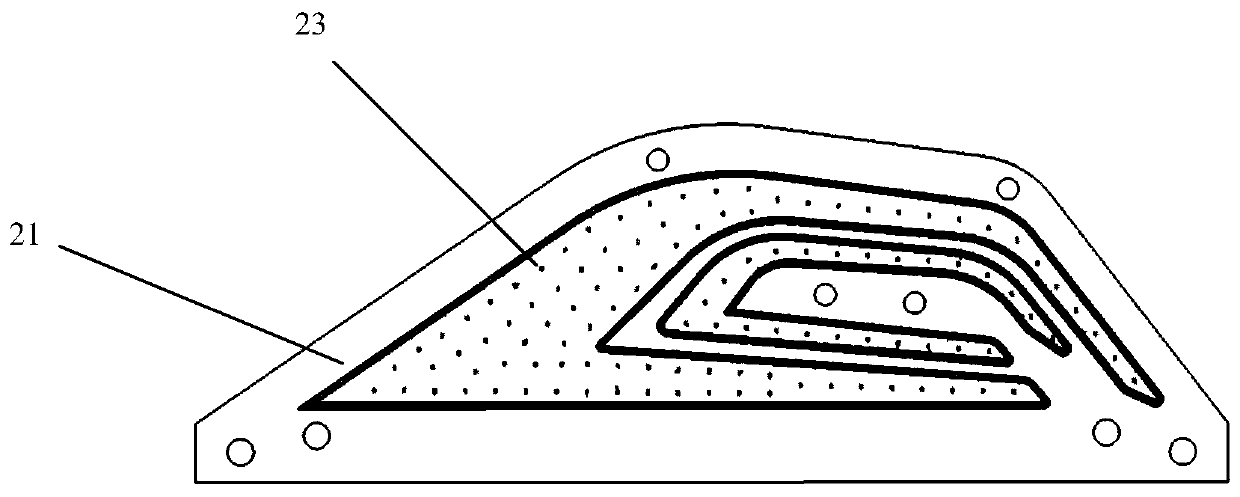

[0031] A kind of installation technology of automobile tail light, please also refer to Figure 1 to Figure 3 , the automobile tail light includes a housing 1, an independent light-emitting unit 2, a lamp cavity 3 and a bracket 4, and the independent light-emitting unit 2 includes a circuit board 21, a lens 22 and an LED lamp 23; the circuit board 21 is arranged on the The above-mentioned support 4, the above-mentioned LED lamp 23 is arranged on the above-mentioned circuit board 21; the above-mentioned independent light-emitting unit 2 and the support 4 are distributed in the above-mentioned lamp cavity 3 in an arc-shaped trajectory; Wherein, the independent lighting unit 2 is installed by the following method:

[0032] Step 1. Acquisition of the cir...

Embodiment 2

[0036] Embodiment 2. A kind of installation process of automobile tail light

[0037] This embodiment mainly describes an installation process of an automobile taillight, and the difference from Embodiment 1 is that the independent light emitting unit 2 includes a pulse width modulation (PMW) module.

Embodiment 3

[0038] Embodiment 3. A kind of installation technology of automobile tail light

[0039] This embodiment describes the installation process of an automobile tail light. The difference from Embodiment 2 is that the high-pressure cleaning pressure described in step 1 is 8Mpa, the baking temperature described in step 3 is 100°C, and the baking temperature described in step 4 is 100°C. The transmittance of the red external lens is 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com