Pile splicing fixing device adopting pile planting method

A technology of fixing device and fixing rod, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problem of downward deformation of anti-slip rubber material, increased labor intensity of operators, and unguaranteed service life of pile fixing device, etc. problem, to achieve the effect of locking installation and ensuring fixed friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to facilitate the understanding of those skilled in the art, the structure of the present invention will be further described in detail with the embodiments in conjunction with the accompanying drawings:

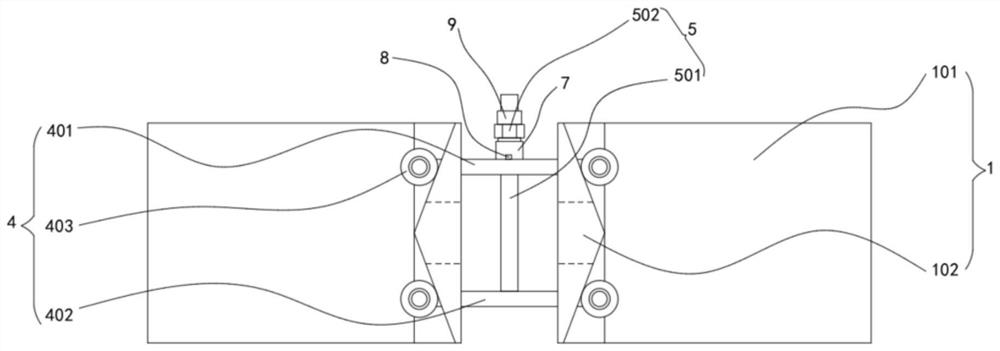

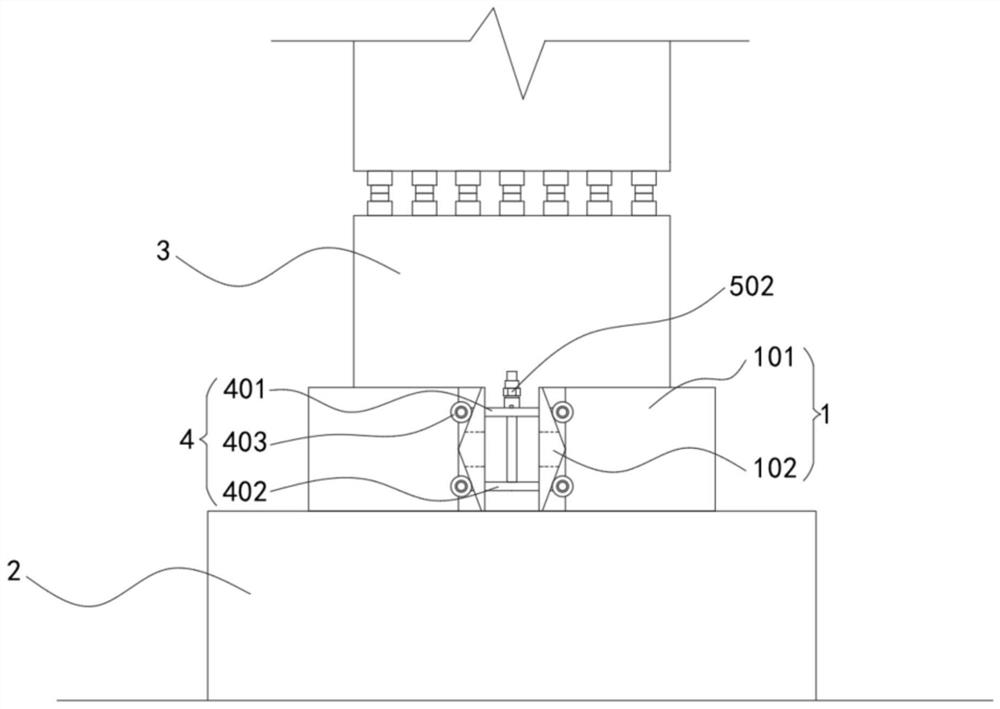

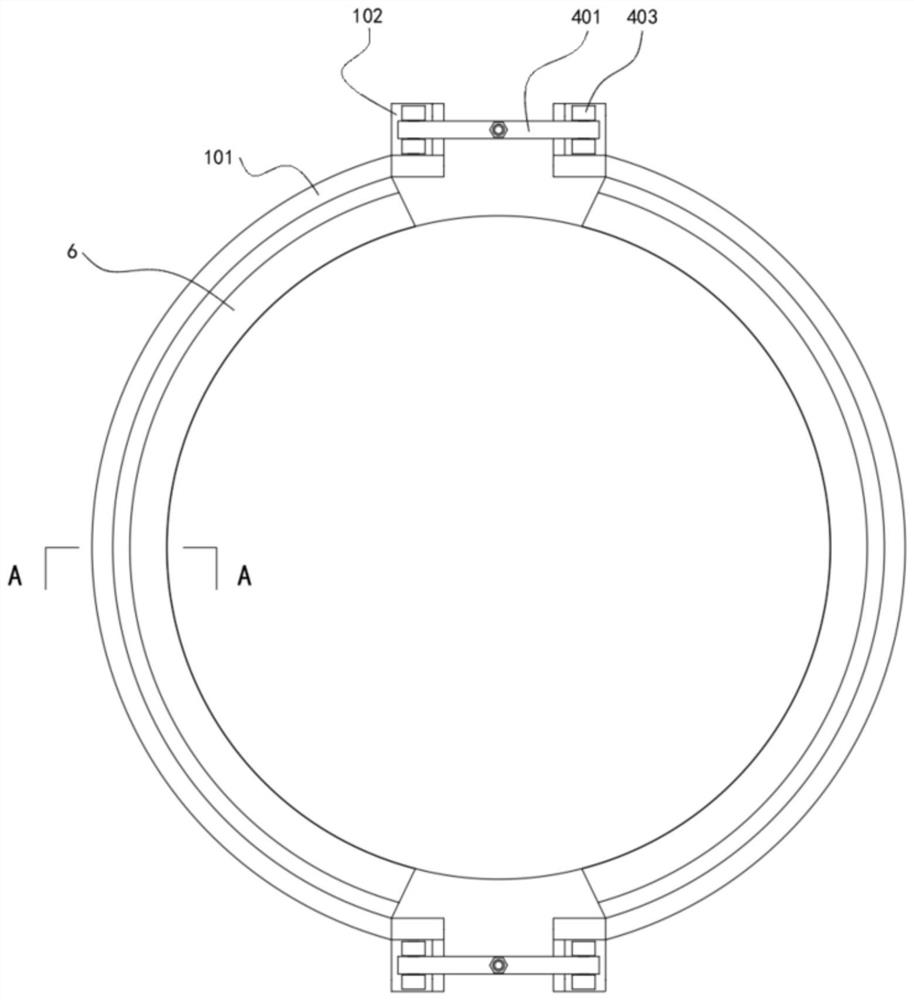

[0035] refer to Figure 1-6 , a planting pile method pile fixing device, comprising

[0036]The fixing mechanism 1 is arranged above the steel casing 2 for fixing the next pile 3. The fixing mechanism 1 includes a set of two symmetrically arranged ring-shaped steel plate fixing hoops 101, and the two ends of the ring-shaped steel plate fixing hoops 101 are Corresponding fixed limit blocks 102 are fixed respectively, and the outer side of the fixed limit blocks 102 is arranged in a straight line, and the inner side of the fixed limit blocks 102 is arranged in an isosceles triangle shape, and the upper and lower ends of the fixed limit blocks 102 Corresponding clamping grooves are respectively provided;

[0037] The locking mechanism 4 is used to lock the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com