A vector control method for direct drive wind power converter without stator voltage measurement

A wind power converter, vector control technology, applied in the direction of electronic commutation motor control, vector control system, motor generator control, etc., can solve the problem of overcurrent, prominent safety hazards, and the initial value of flux linkage without considering the control method, etc. problem to avoid overcurrent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

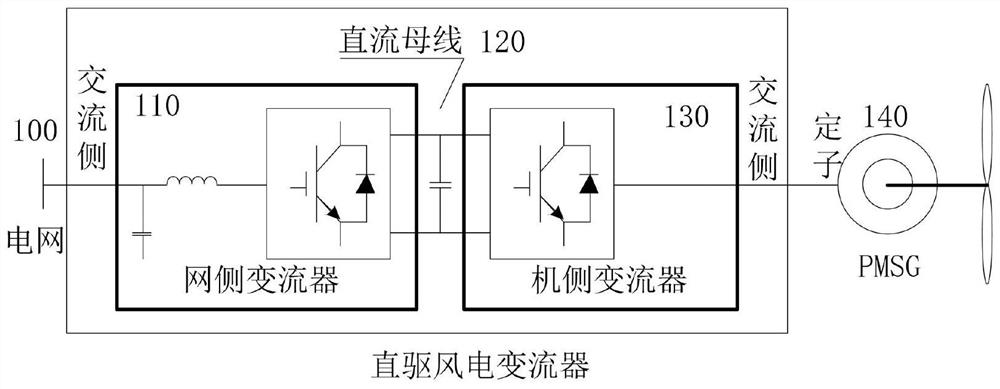

[0070] like figure 1 As shown, the direct-drive wind turbine includes three parts: permanent magnet synchronous generator (PMSG), direct-drive wind power converter and grid.

[0071] The direct-drive wind power converter is divided into two parts, the grid-side converter 110 and the generator-side converter 130. The AC side of the grid-side converter 110 is connected to the grid 100, and the AC side of the generator-side converter 130 is connected to the generator The stator of the machine 140 , the grid-side converter 110 and the machine-side converter 130 are connected together through the DC bus 120 to realize the flexible connection between the generator 140 and the grid 100 .

[0072] The electric energy generated by the wind power converter is integrated into the grid 100, which needs to meet the grid-connected guidelines and grid adapta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com