Textile dust removal device and using method thereof

A technology of dust removal device and main body, applied in the direction of separation method, use of liquid separation agent, chemical instrument and method, etc., can solve the problems of low air filtration efficiency, achieve good filtration effect and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

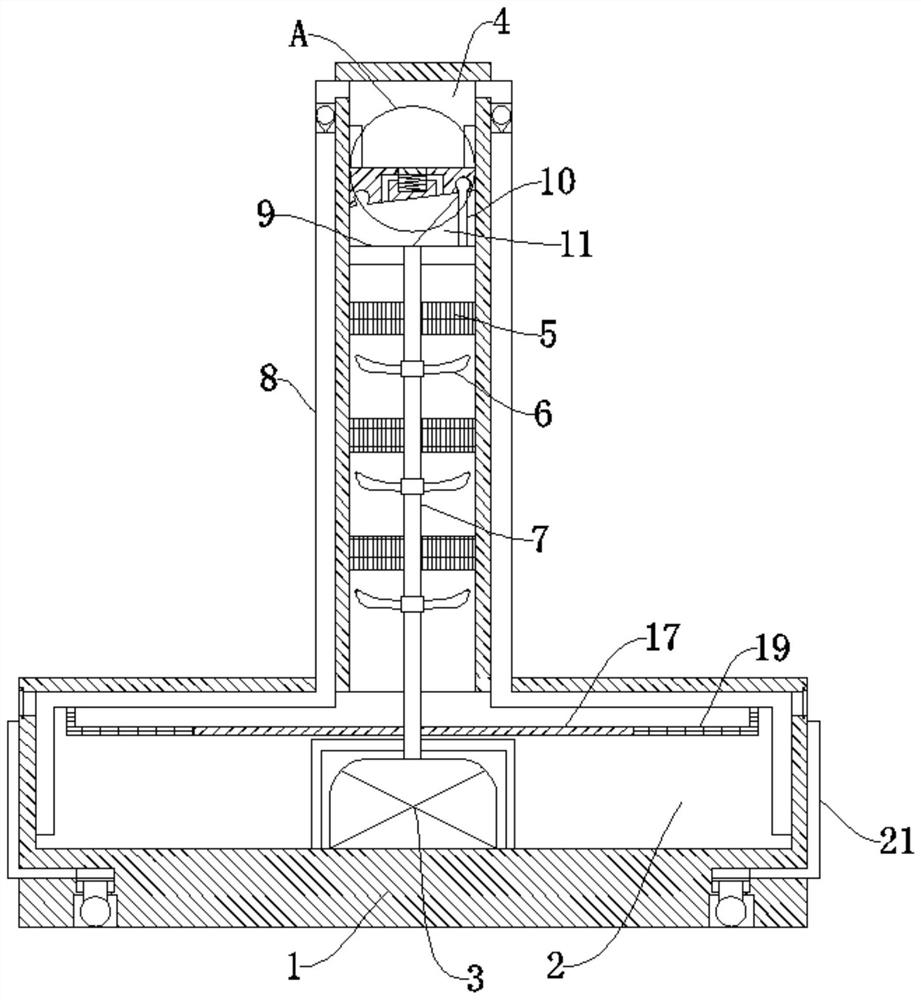

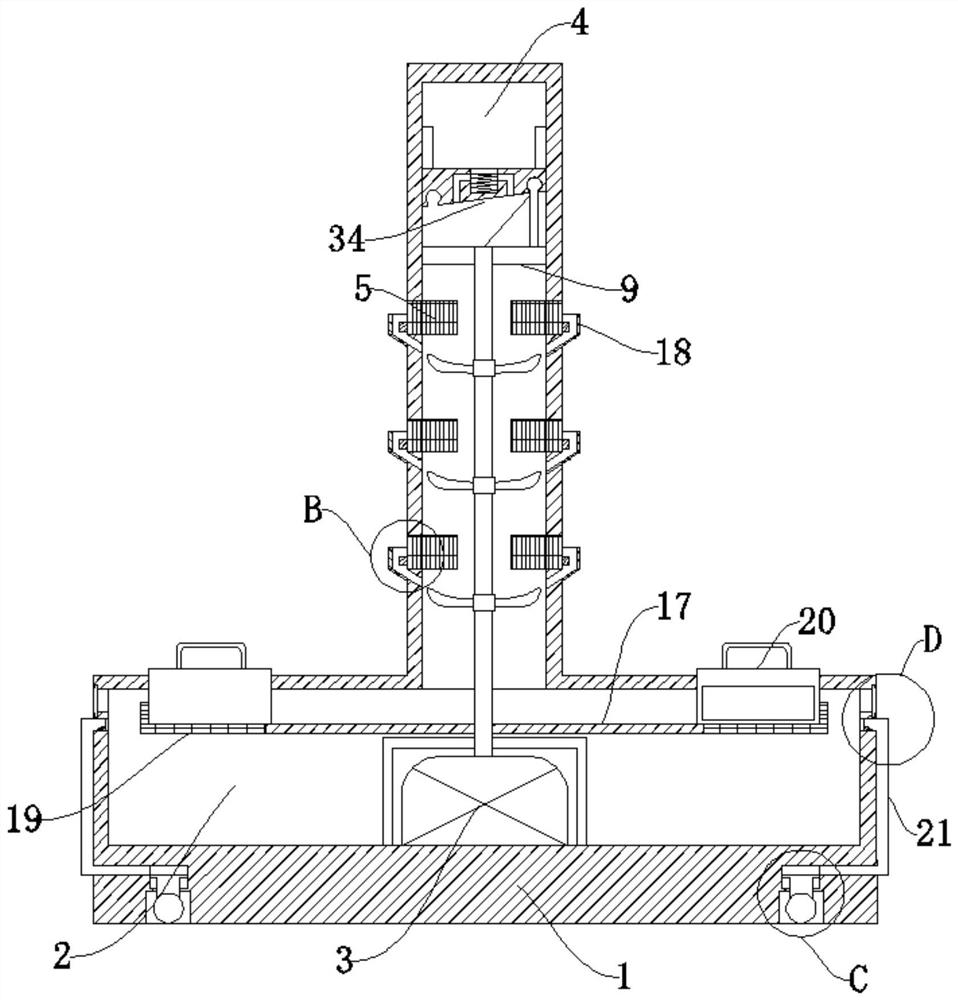

[0032] refer to Figure 1-10 , a textile dedusting device and its use method, comprising a main body 1, a water chamber 2 is provided at the lower end of the main body 1, a drive motor 3 is connected in the water chamber 2, a partition block 34 is slidably connected to the upper end of the main body 1, and the partition block 34 is connected to the main body 1 The upper end forms a suction chamber 4, and the suction chamber 4 is symmetrically connected with a water suction pipe 8, and the end of the water suction pipe 8 away from the water suction chamber 4 is connected with the water chamber 2, and the output end of the driving motor 3 in the water suction pipe 8 is fixedly connected with a rotating shaft 7, and the rotating shaft 7 is fixedly connected with multiple groups of rotating blades 6, and the main body 1 is connected with multiple groups of first filter screens 5, the first filter screen 5 is matched with the rotating blades 6, and the top of the rotating shaft 7 is...

Embodiment 2

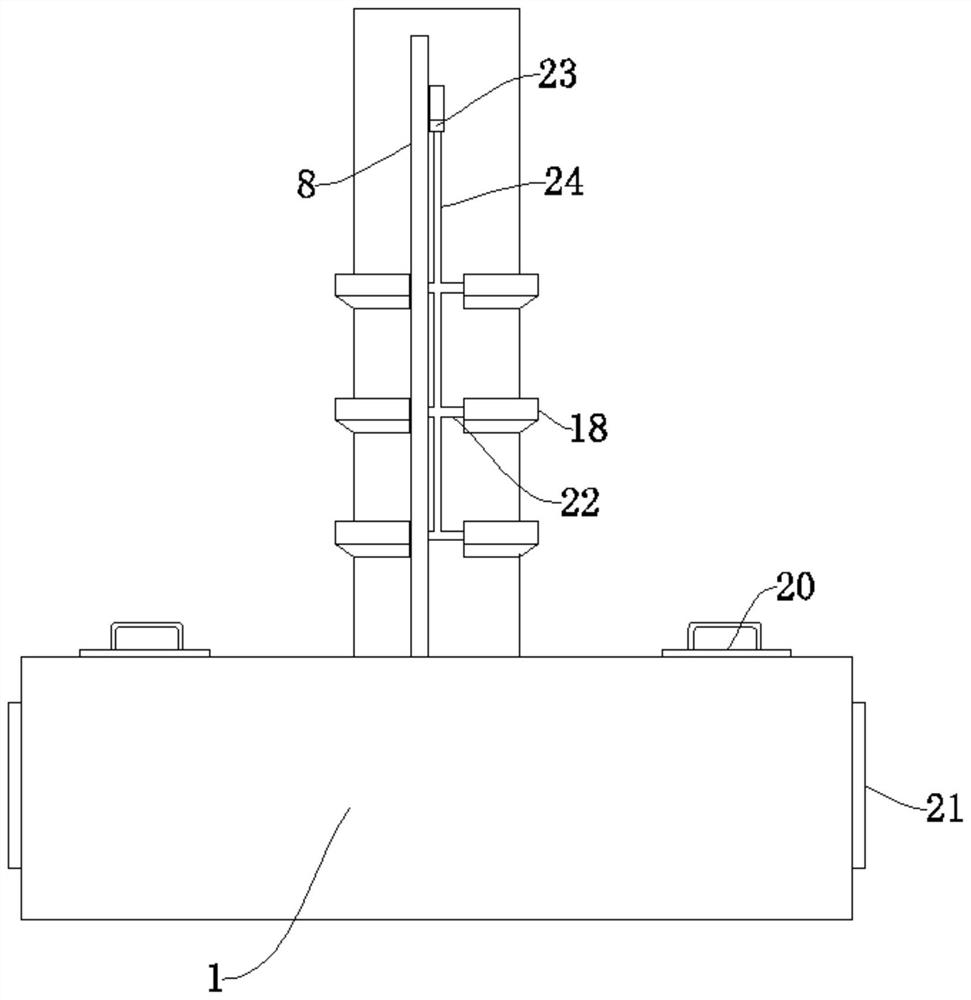

[0036] refer to Figure 1-10 , a textile dedusting device and its use method are basically the same as in Embodiment 1, furthermore: the main body 1 is fixedly connected with multiple sets of first baffles 18 near the first filter screen 5, and the outer wall of the upper end of the main body 1 is slidably connected There are multiple groups of scraping bars 22, the scraping bars 22 are matched with the first baffle plate 18 and the first filter screen 5, the partition block 34 is symmetrically fixedly connected with a slider 23, the slider 23 is slidably connected with the main body 1, and the slider 23 The lower end is fixedly connected with a pull rod 24, and the pull rod 24 is fixedly connected with the scraper rod 22. When the partition block 34 moves up and down, the slider 23 is driven to move up and down, and the pull rod 24 is used to move the scraper rod 22 up and down, and the first filter screen 5 is moved up and down. Sticky textile fibers are scraped into the fir...

Embodiment 3

[0038] refer to Figure 1-10 , a textile dedusting device and its use method are basically the same as in Embodiment 1, furthermore: the lower end of the rotating shaft 7 is fixedly connected with a rotating disc 17, and the side of the rotating disc 17 away from the rotating shaft 7 is fixedly connected with a second filter screen 19 , the main body 1 is slidably connected with a collection box 20, the collection box 20 is attached to the second filter screen 19, the used water falls on the rotating disk 17, and due to the rotation of the rotating disk 17, the rotating disk 17 will be rotated under the action of centrifugal force. The water and impurities on the filter are thrown into the second filter screen 19, and the water leaks into the water chamber 2 from the second filter screen 19. Since the collection box 20 is attached to the second filter screen 19, the water on the second filter screen 19 is Impurities are scraped into the collection box, so that the impurities i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com