Stainless steel basin polishing equipment

A stainless steel and equipment technology, applied in the field of stainless steel basin polishing equipment, can solve problems such as low efficiency and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

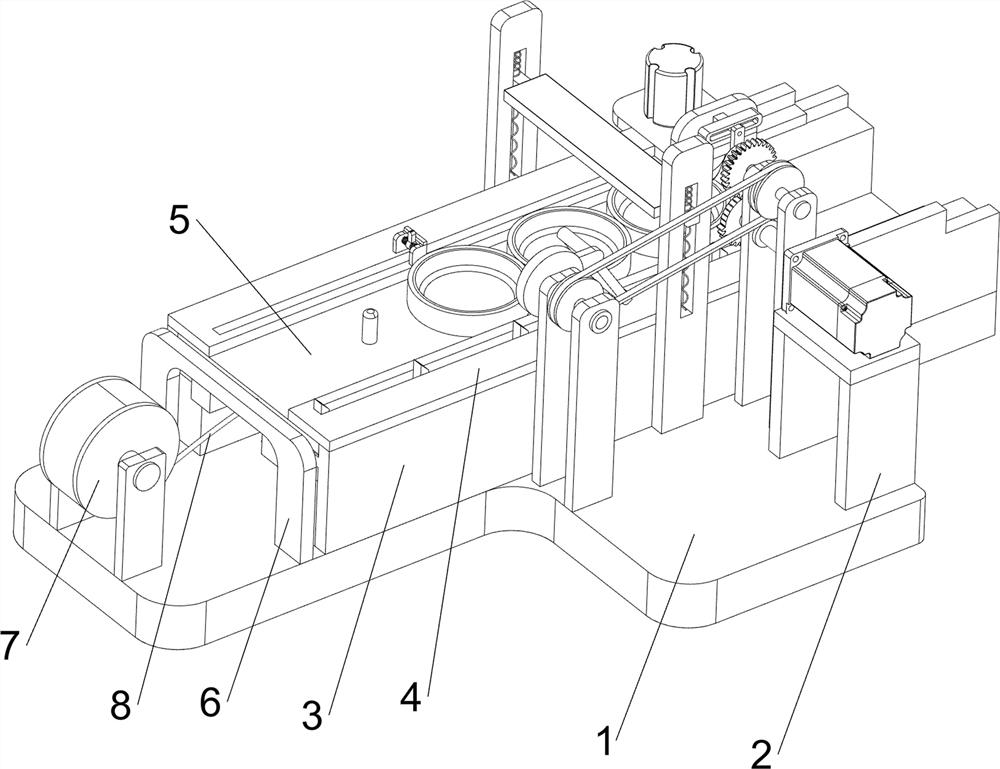

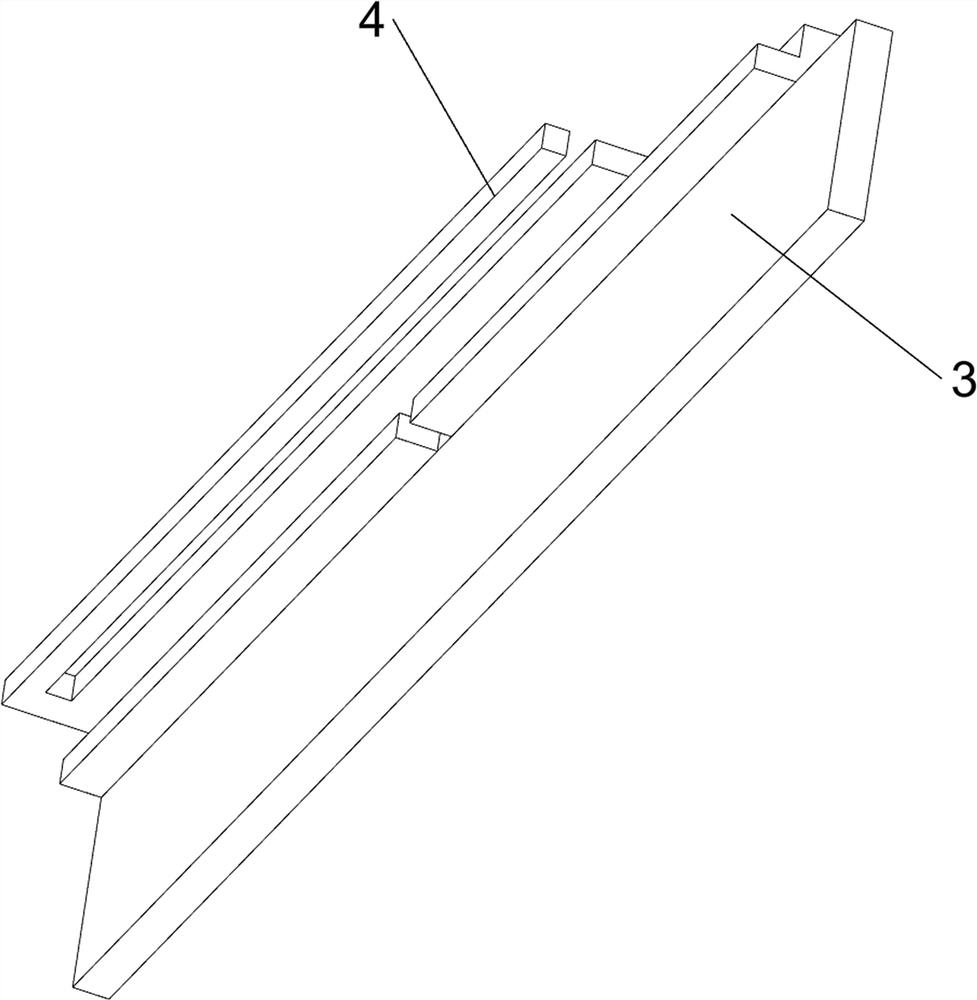

[0022] A stainless steel basin polishing equipment, such as figure 1 and Figure 4 As shown, it includes a base plate 1, a polishing mechanism 2, a support member 3, a first baffle plate 4, a propulsion mechanism 5, a second baffle plate 6, a take-up wheel 7 and a pull wire 8, and a polishing mechanism 2 is provided on the right front side of the upper part of the bottom plate 1. , the upper part of the bottom plate 1 is provided with a symmetrical front and rear supporting member 3, the supporting members 3 on the front and rear sides are respectively provided with a first baffle plate 4, the supporting members 3 on the front and rear sides are provided with a propulsion mechanism 5, and the left side of the upper part of the bottom plate 1 is provided with There is a second baffle plate 6, the second baffle plate 6 is located on the left side of the support member 3 on the front and rear sides, and a take-up wheel 7 is arranged in the middle of the left side of the upper par...

Embodiment 2

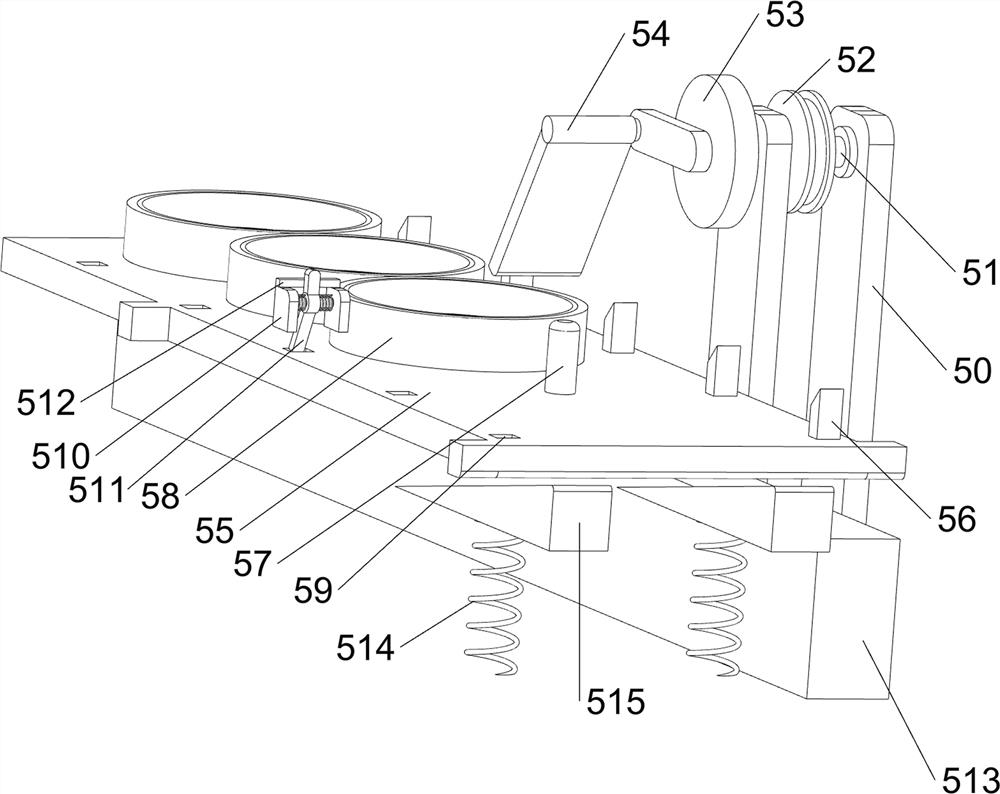

[0025] On the basis of Example 1, such as Figure 2-3 As shown, the polishing mechanism 2 includes a support frame 20, a first servo motor 21, a first bearing seat 22, a missing gear 23, a first rotating shaft 24, a full gear 25, a first rotating rod 26, a connecting block 27, and a guide block 28 , the first spring 29, the lifting rod 210, the connector 211, the second servo motor 212 and the grinding block 213, the upper right side of the base plate 1 is provided with a support frame 20, the support frame 20 top is provided with the first servo motor 21, the base plate 1 top The front and rear sides of the right side are symmetrically provided with a first bearing seat 22, and the first bearing seats 22 on the front and rear sides are located on the rear side of the support frame 20, and the output shaft of the first servo motor 21 passes through the first bearing seats 22 on the front and rear sides. The output shaft of the first servo motor 21 is provided with a missing ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com