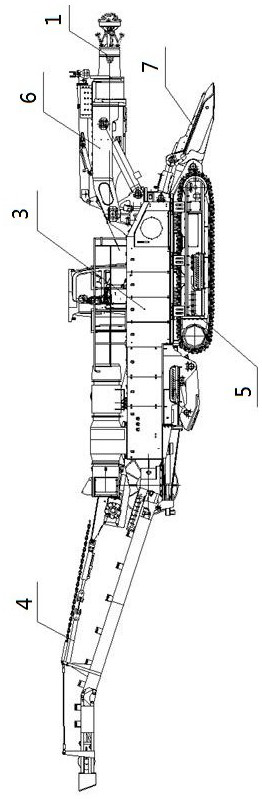

A cantilever boring machine and its construction method

A technology of cantilever roadheader and roadheader, which is applied in earthwork drilling, mining equipment, tunnels, etc. It can solve the problem that the cantilever roadheader cannot change the diameter of excavation, and achieve high excavation flexibility and applicability, and high promotion value , Guarantee the effect of excavation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

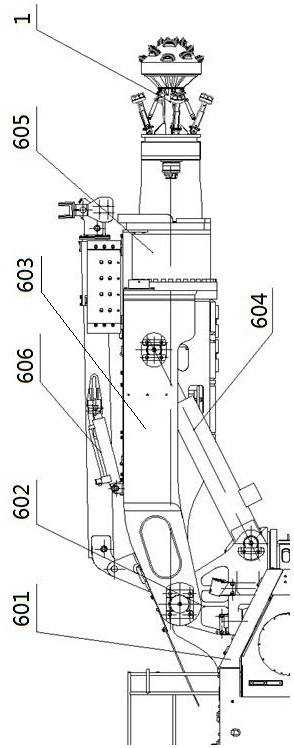

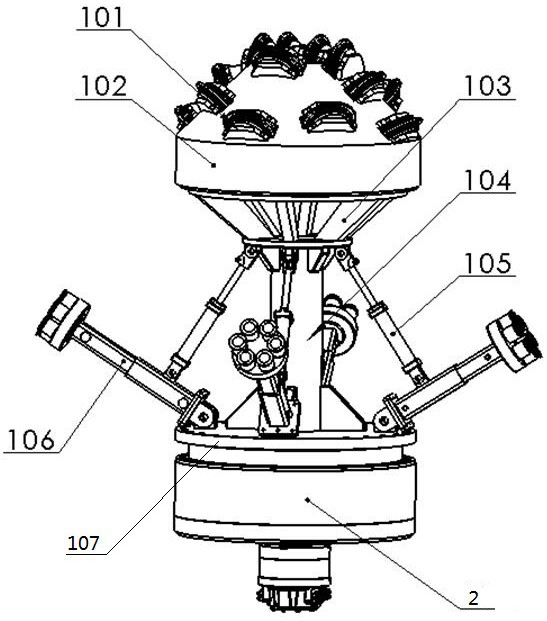

[0042] Embodiment 4: as Image 6 , 7 Shown, a kind of construction method of cantilever boring machine as described in embodiment 3, the steps are as follows:

[0043] S1: Adjust the position of the cantilever roadheader so that the cantilever roadheader is at an appropriate distance from the tunnel face, and fully shrink the telescopic cantilever arm 106 of the expanding and cutting device 1 to the rear of the central cutter head 102; The diameter of the telescopic cantilever arm is not greater than the maximum diameter of the central cutter head,

[0044] S2: The telescopic control cylinder 606 drives the telescopic arm 605 and the expanding and cutting device 1 to excavate along the face until the central cutter head 102 of the expanding and cutting device 1 is completely excavated into the face; that is, the main drive 2 passes through the support The disk 107 drives the combined excavation device 1 to excavate along the excavation surface, and the central cutterhead 102...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com