Expanding and supporting device and tyre mould

A technology of spreaders and support frames, applied in the field of spreaders and tire molds, can solve the problems of reducing labor intensity and high safety hazards, sliding and collapsing of supporting parts, and time-consuming safety factor, so as to reduce labor intensity and avoid The effect of scratching and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

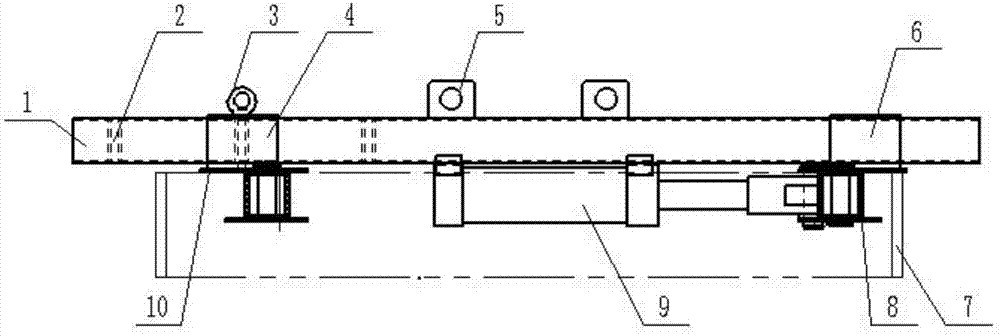

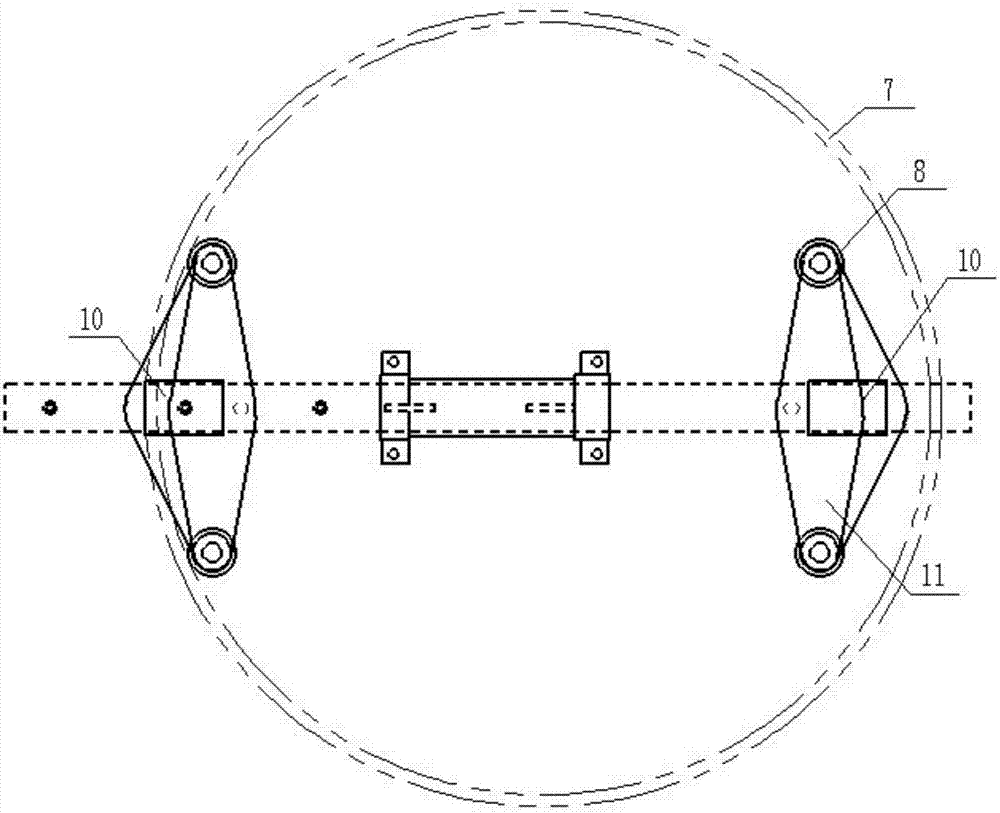

[0035] Such as figure 1 As shown, an expander includes an expansion device, and the expansion device is provided with a plurality of supporting legs 11. When expanding, the ends of the supporting legs 11 are in sliding contact with the inner wall of the ring body 7 to be expanded, so that the expansion process can be realized. The tonality contact avoids the accident of the support part slipping out and hurting people due to the constant change of the force angle when the support is expanded. In order to further ensure the stability of the sliding contact adjustment, the end of the supporting leg 11 is preferably provided with a certain radian, so that the end of the supporting leg 11 is in linear contact with the inner wall of the ring body 7 to be expanded, reducing the friction during the adjustab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com