Sand mold hardness tester capable of realizing online automatic detection

A sand mold hardness and automatic detection technology, which is applied in the field of sand mold hardness testers, to eliminate positioning errors and achieve close contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings.

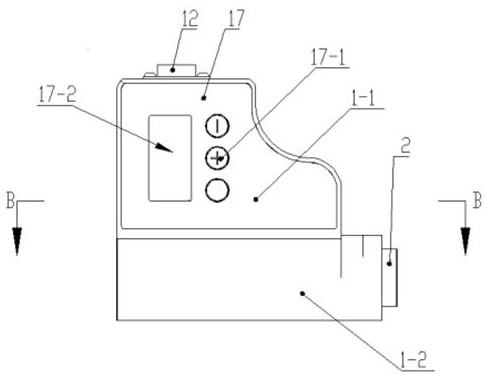

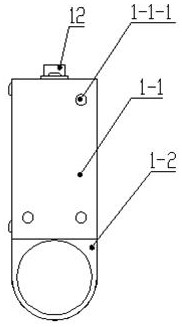

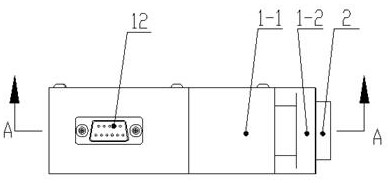

[0044] Such as Figure 1 to Figure 5 As shown, the technical solution adopted by the present invention includes an upper casing 1-1 and a lower casing 1-2, and the upper casing 1-1 and the lower casing 1-2 are fixed by first screws 23 and second screws 20 connection, a presser foot 2 and a displacement sensor 7 are installed in the lower housing 1-2, the presser foot 2 is a retractable presser foot, and a presser head 4 is installed in the retractable presser foot 2, and the presser head 4 The left end of the pressure head 4 is fixedly connected with the moving iron core of the displacement sensor 7, and the moving iron core of the displacement sensor 7 is driven by the movement of the pressure head 4 to move, and the left end of the pressure head 4 is equipped with a loading spring 10, and the retractable pressure foot 2 A presser foot return spring 6 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com