Method for adjusting horn mouth of circle shears by applying orthogonal method

A technology of disc shears and bell mouths, which is applied in the field of orthogonal measurement and adjustment of the dimensional accuracy of cold-rolled disc shears and bell mouths. To achieve the effect of solving the problems of accurate measurement and accurate adjustment, reducing the amount of product waste and quality objections, and reducing the consumption of spare parts and expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

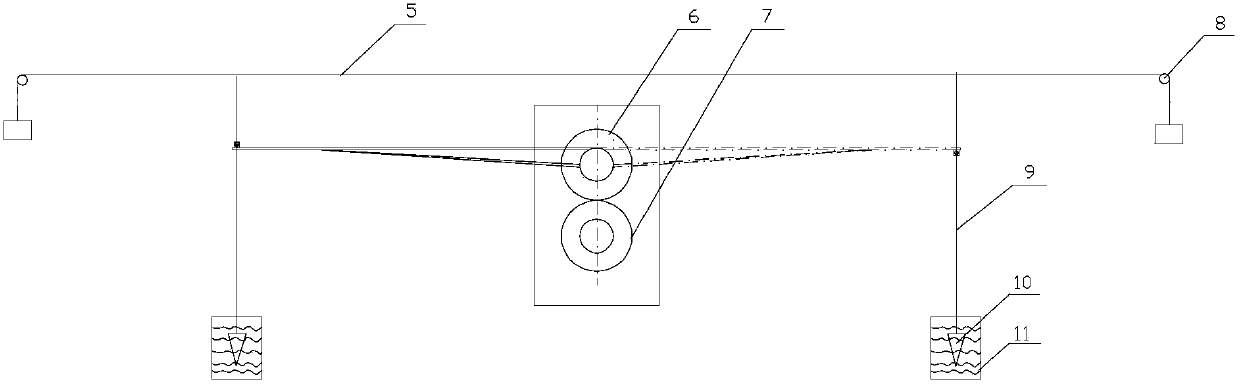

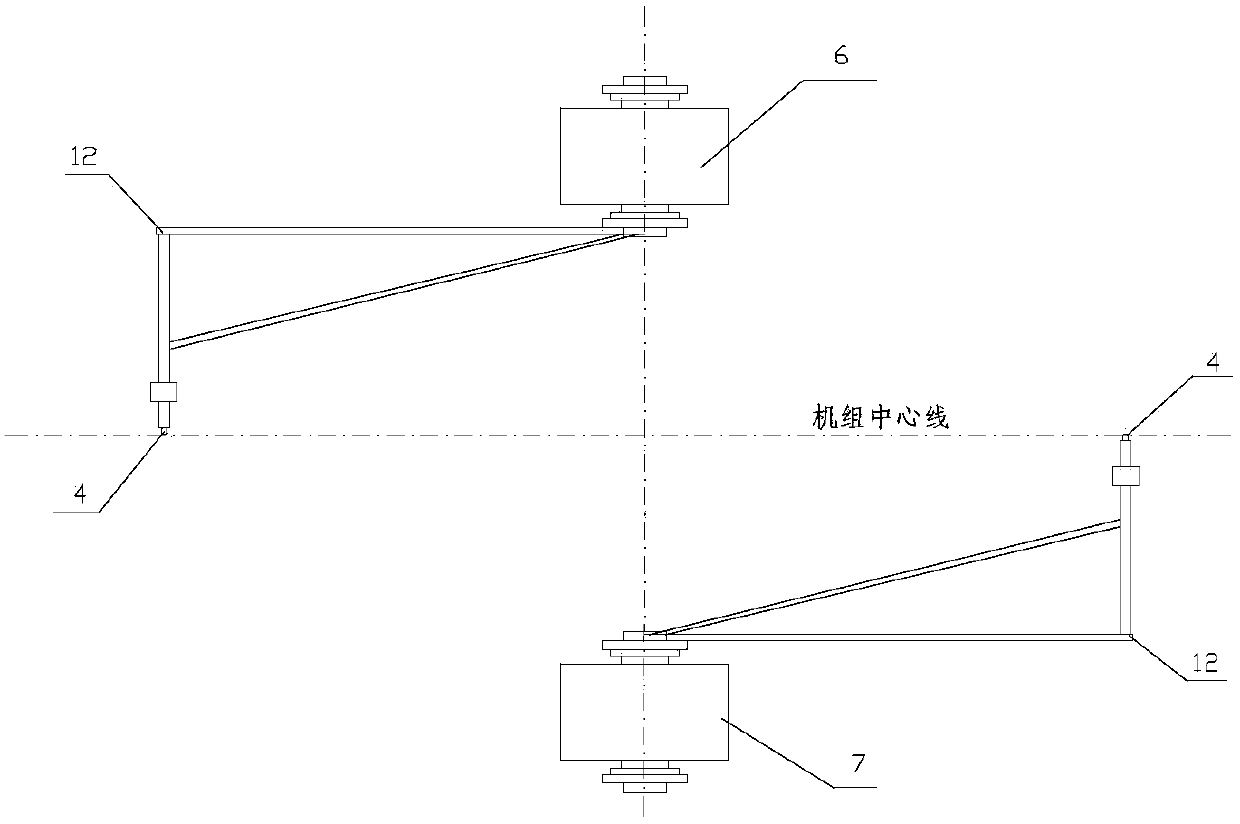

[0020] The method for adjusting the bell mouth of the disc shears by the orthogonal method of the present invention is mainly composed of a unit center line, two vertical lines 9 leading down from the center line, a pendulum 12 suitable for the detection conditions of the disc shears, and a The inner diameter micrometer 4 on the fork 12 realizes. Using the orthogonal method to amplify the measurement error value through the inner diameter micrometer 4, accurately and quickly measure and adjust the bell mouth state of the disc shears on both sides. Its specific method and steps are:

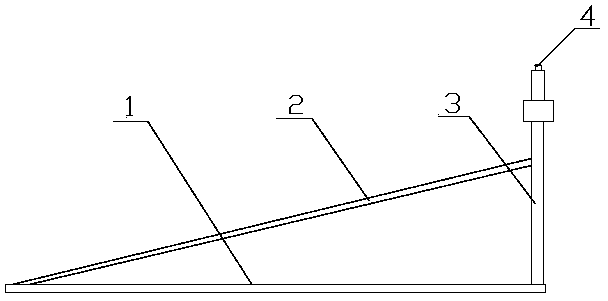

[0021] 1. Make a swing rod 12. The swing rod 12 is composed of a main rod 1 and a vertical rod 3. The length of the main rod 1 is 1.5 meters, and a reinforcing rod 2 is obliquely connected between the main rod 1 and the vertical rod 3 (see figure 1 ).

[0022] 2. Establish the center line of the unit, such as figure 2 As shown, the center wire frame 8 is welded with profiles, and the distance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com