Optical lens and imaging equipment

An optical lens and imaging surface technology, applied in optics, optical components, instruments, etc., can solve the problem that the imaging quality of the lens is greatly affected, and achieve the effect of improving the camera experience, realizing the balance of high pixels, and realizing miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

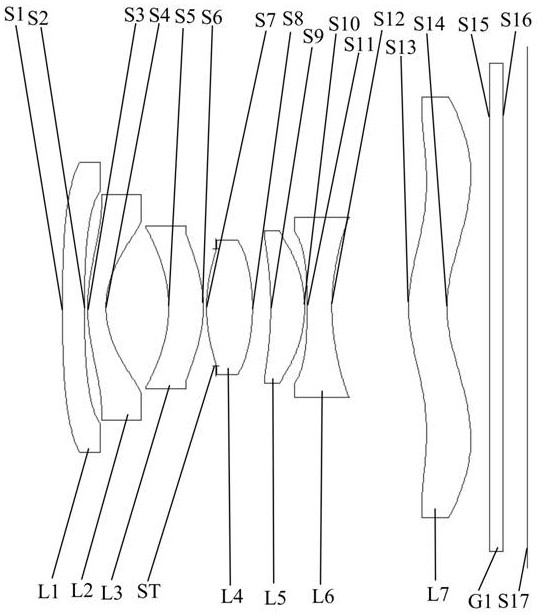

[0080] In the first embodiment of the present invention, the vertical distance between the inflection point of the object side S13 of the seventh lens and the optical axis is 1.935 mm, and the sagittal height relative to the center of the object side S13 of the seventh lens is 0.289 mm. The vertical distance between the inflection point of the image side S14 and the optical axis is 2.035 mm, and the sagittal height relative to the center of the image side S14 of the seventh lens is 0.371 mm.

[0081] Please refer to Table 1, the relevant parameters of each lens in the optical lens provided by the first embodiment of the present invention are shown in Table 1.

[0082] Table 1

[0083]

[0084] The surface coefficients of each aspheric surface of the optical lens provided by the first embodiment of the present invention are shown in Table 2.

[0085] Table 2

[0086]

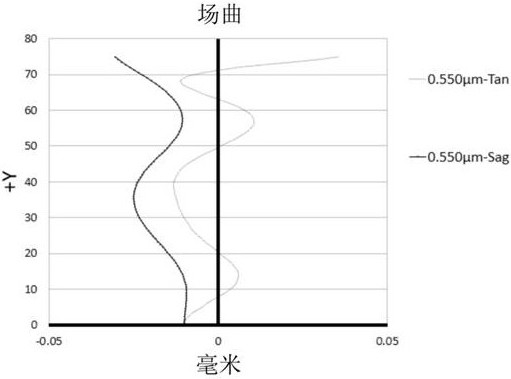

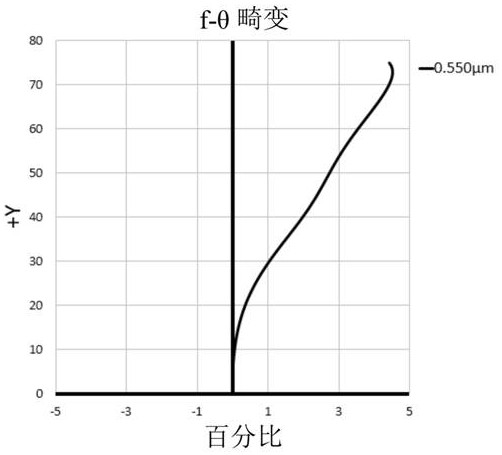

[0087] see figure 2 , image 3 , Figure 4 and Figure 5 , respectively show the field curvature ...

no. 2 example

[0093] The structure of the optical lens provided by the second embodiment of the present invention is substantially the same as that of the optical lens provided by the first embodiment, except that the curvature and material selection of each lens are different.

[0094] In the second embodiment of the present invention, the vertical distance between the inflection point of the object side S13 of the seventh lens and the optical axis is 1.835 mm, and the sagittal height relative to the center of the object side S13 of the seventh lens is 0.251 mm. The vertical distance between the inflection point of the image side S14 and the optical axis is 1.955 mm, and the sagittal height relative to the center of the image side S14 of the seventh lens is 0.336 mm.

[0095] Please refer to Table 3, the relevant parameters of each lens in the optical lens provided by the second embodiment of the present invention are shown in Table 3.

[0096] table 3

[0097]

[0098] The surface coe...

no. 3 example

[0107] The structure of the optical lens provided by the third embodiment of the present invention is substantially the same as that of the optical lens provided by the first embodiment, except that the curvature and material selection of each lens are different.

[0108] In the third embodiment of the present invention, the vertical distance between the inflection point of the object side S13 of the seventh lens and the optical axis is 1.795 mm, and the sagittal height relative to the center of the object side S13 of the seventh lens is 0.217 mm. The vertical distance between the inflection point of the image side S14 and the optical axis is 1.912 mm, and the sagittal height relative to the center of the image side S14 of the seventh lens is 0.298 mm.

[0109] Please refer to Table 5, the relevant parameters of each lens in the optical lens provided by the third embodiment of the present invention are shown in Table 5.

[0110] table 5

[0111]

[0112] The surface coeffi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com