PCB element positioning method based on soldering point color distribution

A color distribution and positioning method technology, applied in image analysis, computer parts, image data processing, etc., can solve problems such as low efficiency and cumbersome positioning methods, and achieve the effect of accurately determining the position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

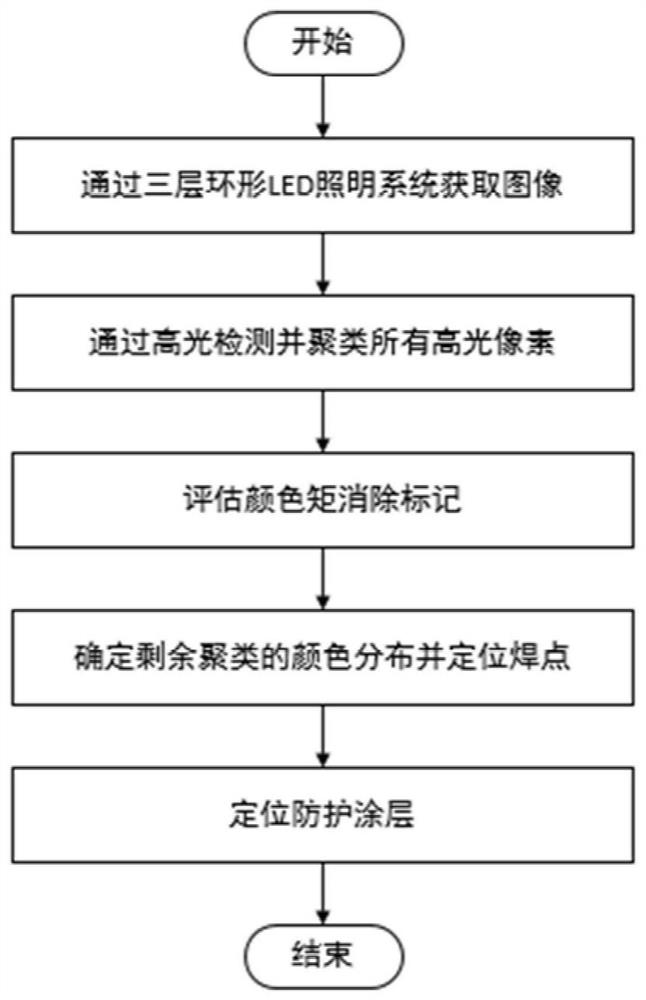

[0052] as attached figure 1 As shown, a kind of PCB component positioning method based on solder joint color distribution provided by the present invention comprises the following steps:

[0053] S01: Acquire the image of the PCB circuit board, extract the high-light pixels in the image, and cluster the high-light pixels according to the distance to form a high-light cluster; wherein, in the present invention, the PCB circuit board image is obtained through a three-layer ring LED lighting system. Specifically include:

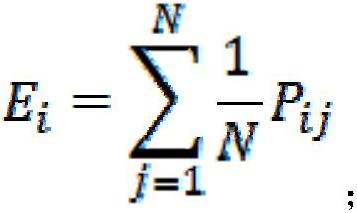

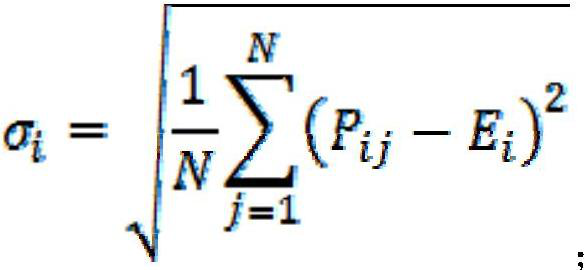

[0054] S011: reduce the brightness and contrast of the image; preprocess the image and reduce the brightness and contrast of the image by the following formula:

[0055]p'=[(p+(b+100)×1.27)-127]×[(c+100)×0.01]+127 (1)

[0056] where p is the original pixel, the brightness coefficient b∈(-100, 100), and the contrast coefficient c∈(0, 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap