Device for improving purity of discard tobacco and multi-stage impurity-removal method for discard tobacco

A technology of purity and shredded tobacco, which is applied in the field of tobacco, can solve the problems of difficult to meet the quality requirements of recycled shredded tobacco, manual picking, etc., and achieve the effect of improving purity and use value, high automation level, and high yield of shredded tobacco

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0062] Example 1

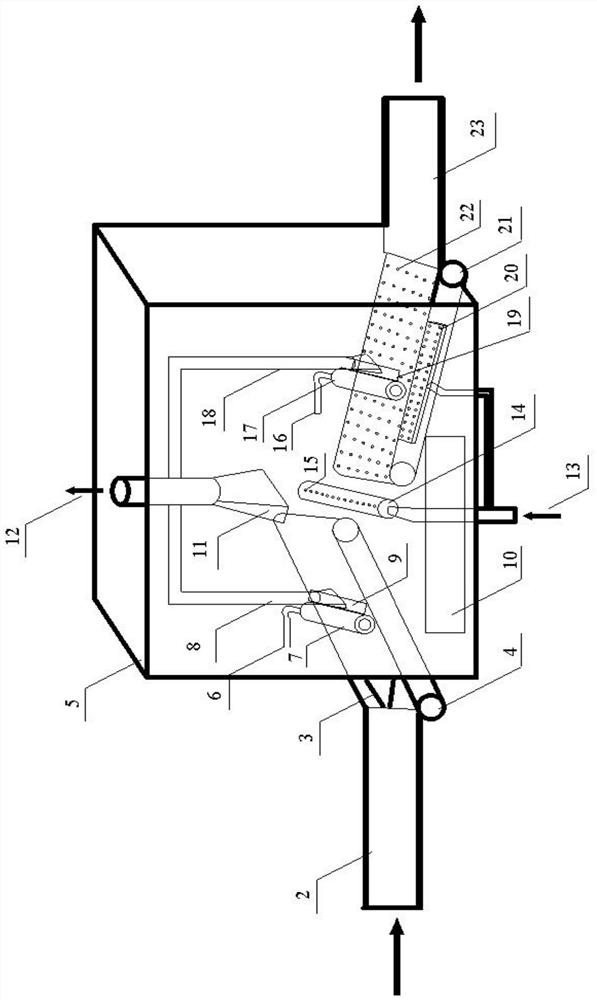

[0063] like figure 1 As shown, Embodiment 1 is a device for improving the purity of waste tobacco shredded tobacco, including:

[0064] Inlet shredded tobacco conveyor belt 2, outlet shredded tobacco conveyor belt 23, shredded tobacco thinning device 3, uphill variable frequency vibration transmission device 4, first electrostatic roller 7, second electrostatic roller 17, first synchronous toothed belt 6, second synchronous toothed Belt 16, first negative pressure shredding device 8, second negative pressure shredding device 18, first scraper 9, second scraper 19, positive pressure adjustable blowing device 14, negative pressure dust removal device 11, Downhill vibration transmission device 21, dust cover 5, heavy debris collection box 10, negative pressure dust removal gas pipe 12, positive pressure blowing gas pipe 13, gas distributor 20;

[0065] Wherein, the shredded tobacco thinning device 3 is arranged on the front end of the up-slope variable-freque...

Example Embodiment

[0079] Example 2

[0080] A multi-stage impurity removal method for waste tobacco cut tobacco. The waste tobacco cut tobacco mixture contains tobacco cut and non-tobacco sundries, the non-tobacco sundries include scraps of paper, dust and other sundries lighter than cut tobacco, and also includes tow, Metals, rubber blocks and other impurities heavier than shredded tobacco; the multi-stage impurity removal method is carried out using the device for improving the purity of waste tobacco shredded tobacco described in Example 1, including the following steps:

[0081] A. Thinning process of waste tobacco shredded tobacco

[0082] The waste tobacco shredded tobacco mixture is transported to the shredded tobacco thinning device 3 through the inlet tobacco shredded conveyor belt 2, and the shredded tobacco thinning device 3 acts smoothly and quickly to transition to the up-slope variable frequency vibration transmission device 4, so that the mixture of waste tobacco shredded tobacco...

Example Embodiment

[0091] Example 3

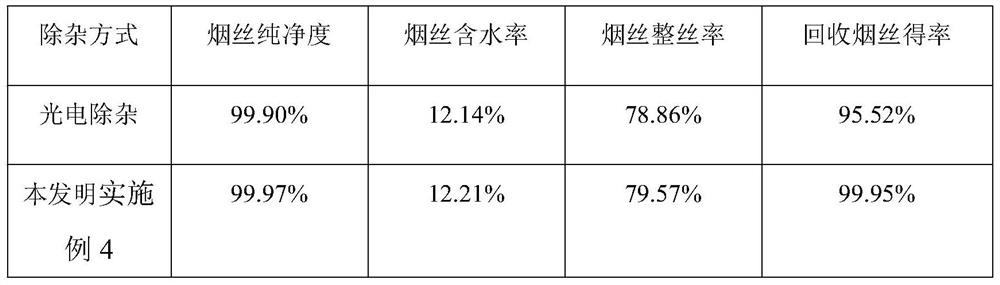

[0092] The experimental object is a waste cigarette processing line with a material flow rate of 2000kg / h in a cigarette production plant. The cigarette waste cigarettes are a certain thin cigarette with a processing capacity of 4000kg. The standard requirement for the purity of shredded tobacco for the recycled shredded tobacco is 99.90%. The waste tobacco treatment amount of the thin cigarettes of this specification is divided into two equal parts, and the waste tobacco cut tobacco is purified and impurity-removed by manual sorting and the impurity-removing method of Example 2 of the present invention.

[0093] Table 1 Comparative analysis of the results after manual sorting and the impurity removal treatment of Example 2 of the present invention

[0094]

[0095] As can be seen from Table 1, two kinds of impurity removal methods have no obvious influence on the cut tobacco quality index cut tobacco moisture content and the whole cut tobacco rate after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com