Paper-plastic cup

A paper-plastic cup and inner cup technology, applied in the field of paper cups, can solve problems such as not easy to observe, and achieve the effects of long hot beverage retention time, not easy to run off, and enhanced anti-scalding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

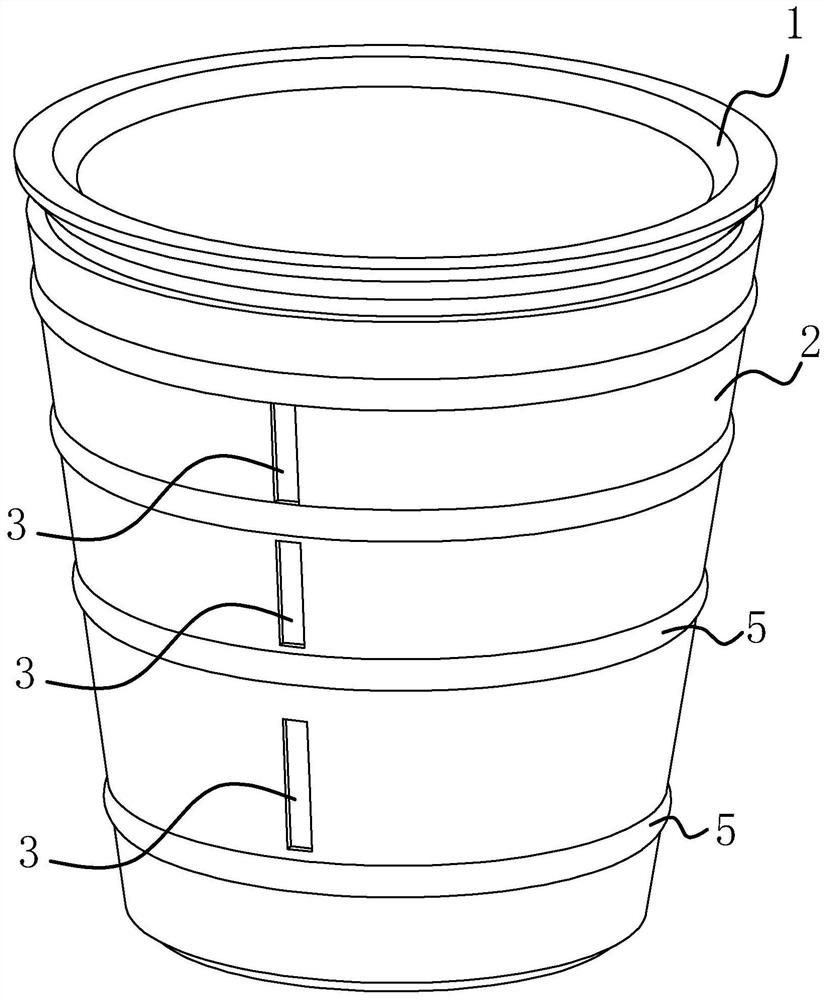

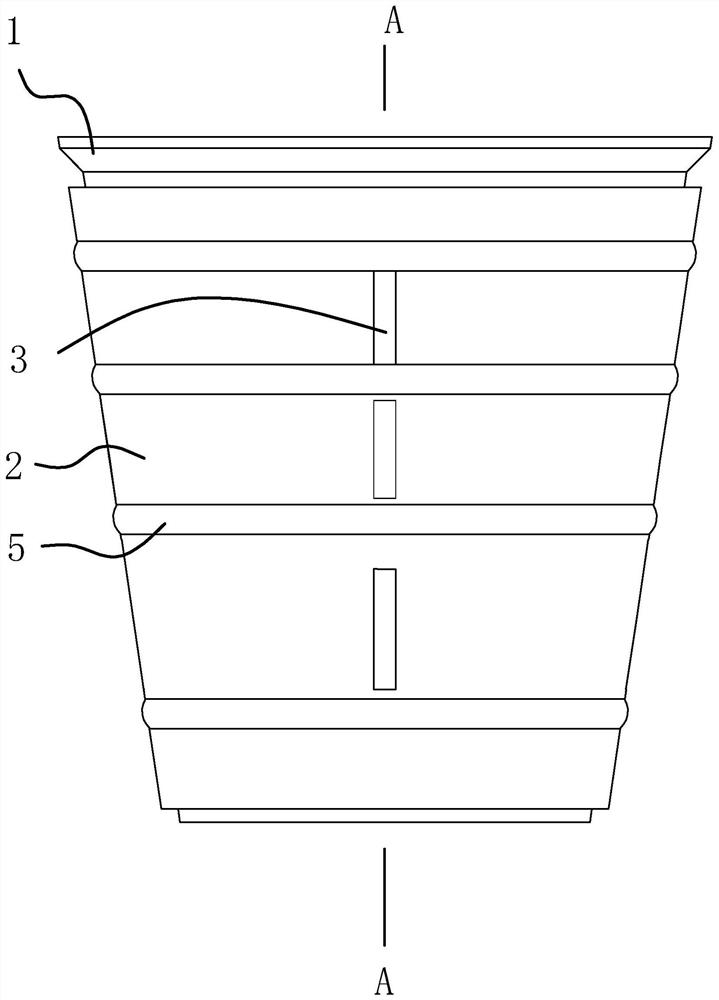

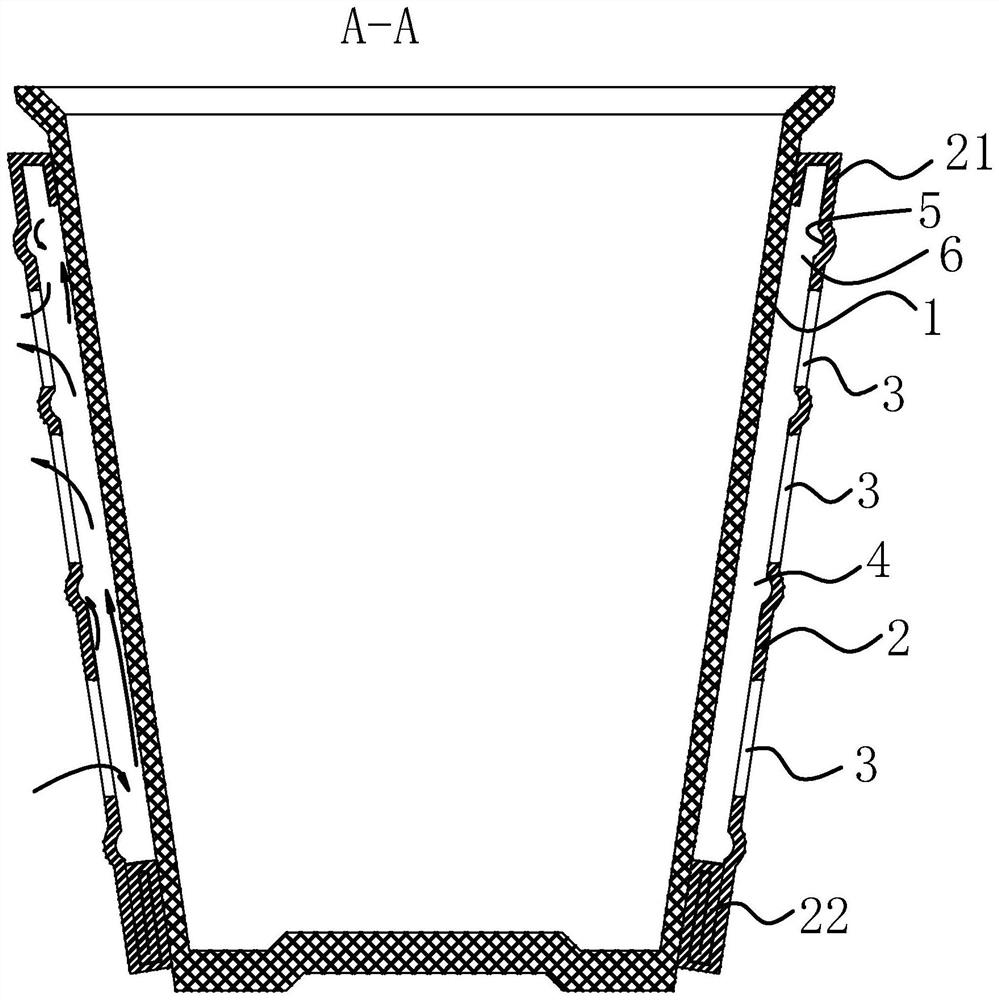

[0022] Such as figure 1 , figure 2 and image 3 As shown, the paper-plastic cup includes an inner cup 1 made of transparent plastic and a cylindrical jacket 2 outside the inner cup 1. The inner cup 1 and the cylindrical jacket 2 form a double-layer anti-scald structure. On the basis, Observe the condition of the inner cup 1 by setting linearly arranged strip-shaped holes 3, and form suitable air convection through one or two linearly arranged strip-shaped holes 3 and other structures, so as to keep the upper part of the paper-plastic cup to maintain heat. The lower section improves scald protection. details as follows:

[0023] The inner cup 1 is made of transparent plastics such as PP or PE, and its shape can be a general cup with a taper.

[0024] The cylindrical jacket 2 is made of paper material, and its upper and lower ends have curling structures that increase the distance from the inner cup 1 wall. Between the outer walls of the inner cup 1 there are heat insulati...

Embodiment 2

[0029] The content of embodiment 2 is basically the same as that of embodiment 1, the difference lies in the shape of the inner cup 1 . In this example, the side wall of the inner cup 1 is a straight cylinder side wall, and the cylindrical outer casing 2 is tapered, and the diameter of the upper end is larger than that of the lower end. Increasing the heat insulation gap 4 and the straight side wall can speed up the flow of hot air and prevent the block of air flow on the outer wall of the inner cup 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com