Gravel roadbed backfilling construction method

A construction method and subgrade technology, which can be used in foundation structure engineering, roads, excavation, etc., can solve problems such as subgrade settlement easily, and achieve better anti-settling effect, better stability and anti-settling ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

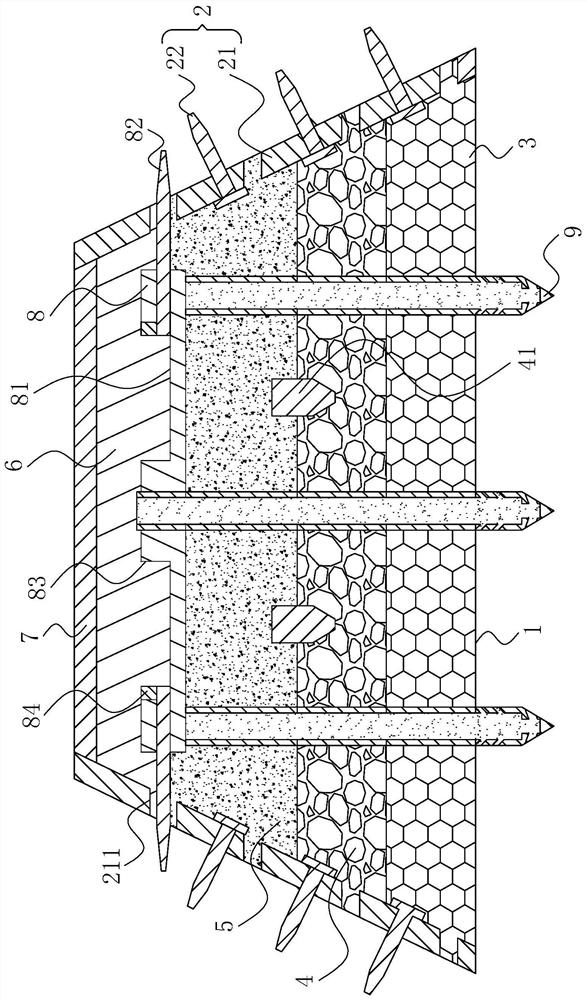

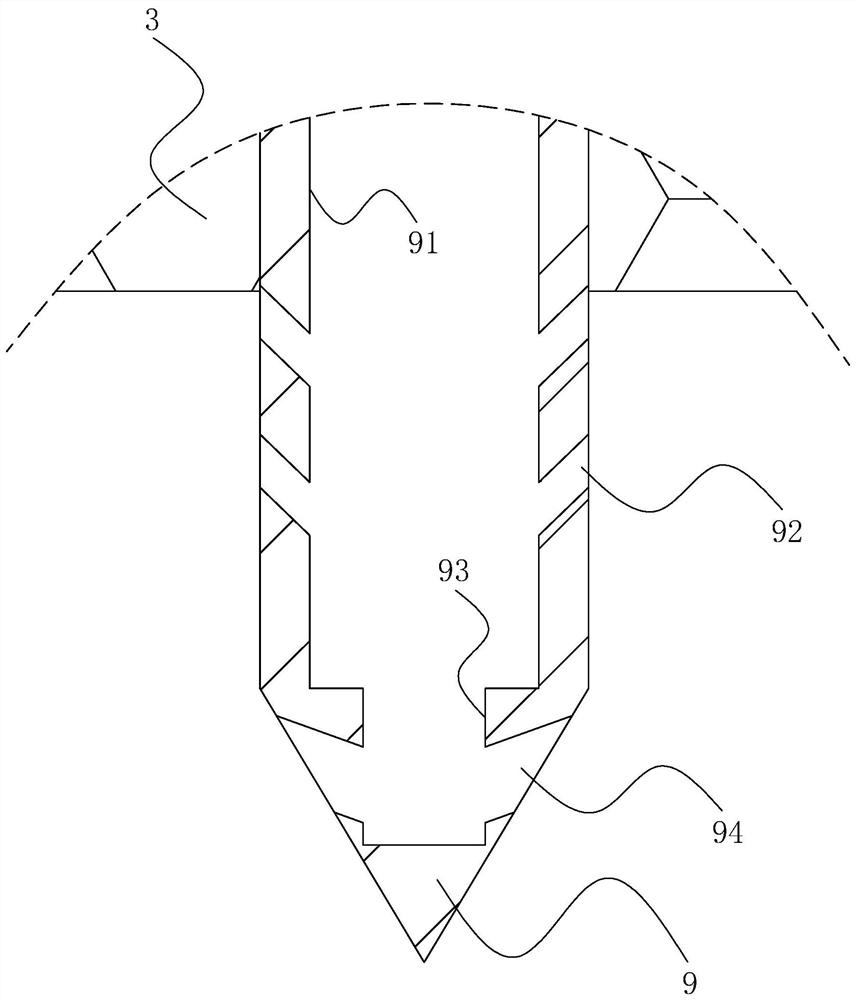

[0052] The following is attached Figure 1-2 The application is described in further detail.

[0053] The embodiment of the present application discloses a construction method for backfilling a gravel subgrade.

[0054] refer to figure 1 and figure 2 , a construction method for backfilling a gravel subgrade, comprising the following steps:

[0055] S1. Remove rubbish around the roadbed, and dig a foundation pit 1 on the ground. The side walls on both sides of the length direction of the foundation pit 1 are relatively inclined. The cross-sectional area of the foundation pit 1 gradually increases from top to bottom to ensure that the foundation pit Under the premise that the excavation of foundation pit 1 is smooth, the stability of the bottom of foundation pit 1 is improved;

[0056] S2. Compacting the bottom wall of the foundation pit 1 to a depth of not less than 10 cm, so that the soil at the bottom of the foundation pit 1 is more compact, and preliminary subgrade se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com