Operating platform for pulling piles, pile pulling device and pile pulling method

A technology for operating a platform and a pile extractor, which is applied in sheet pile walls, buildings, infrastructure engineering, etc., and can solve the problems of building damage, noise pollution, and high costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] The operation platform for the pull pile will be described below.

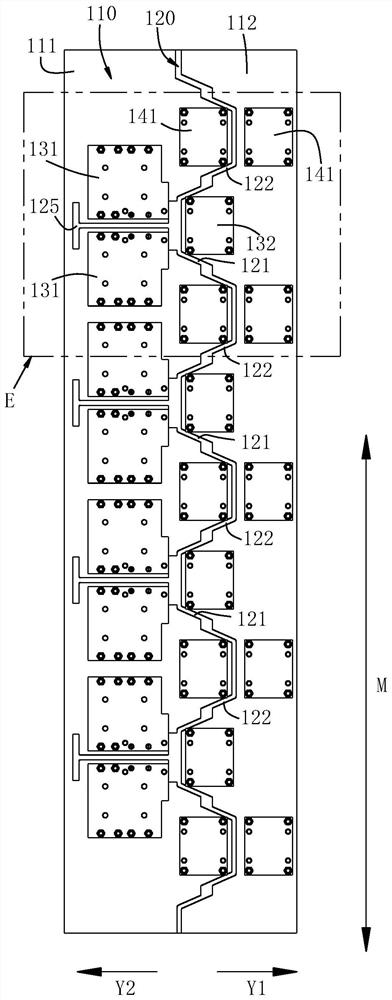

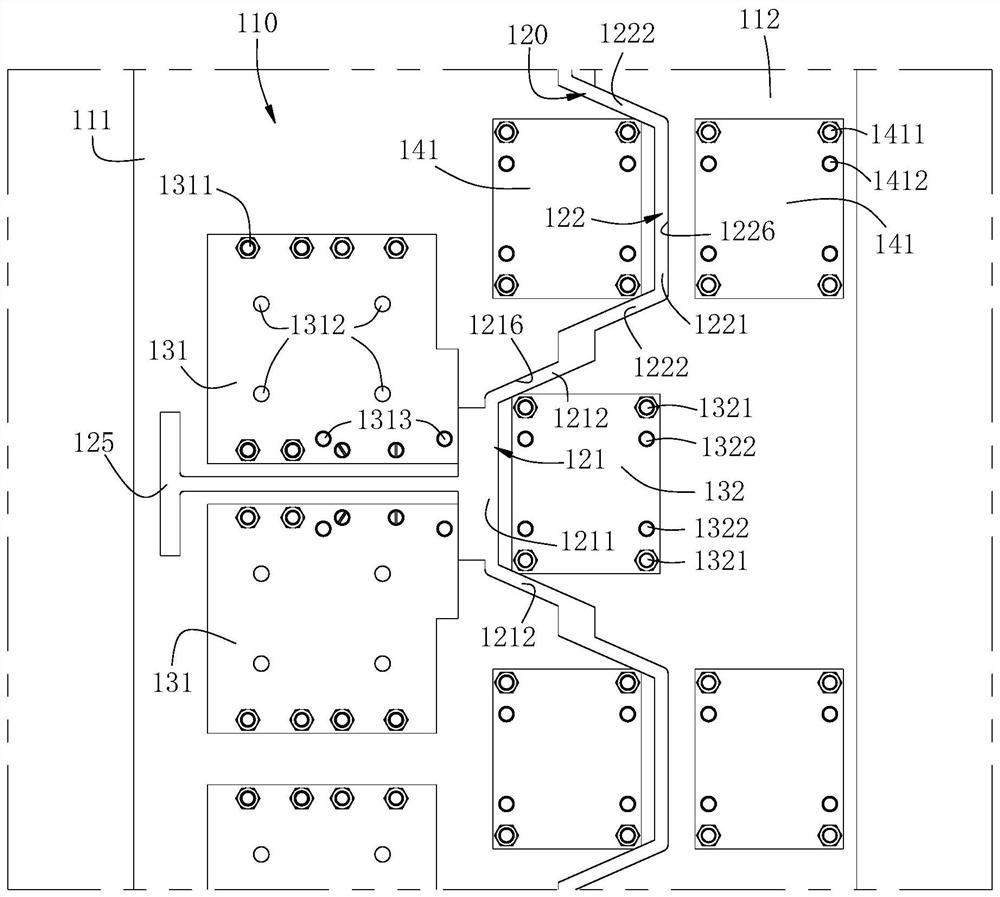

[0075] See Figure 1 - Figure 3 ,exist figure 1 In the arrow marked as m, the arrow indicates the M axis, the direction of the arrow Y1 is the first direction, and the direction of the arrow Y 2 is the second direction. The first direction and the second direction are opposite to the opposite direction, and each is perpendicular to the m axis.

[0076] The operating platform is used to pull out the steel pile in the combined steel plate pile wall. The operating platform includes a support table 110 having an upper surface and a lower surface of the opposite side, and a continuous seam 120 penetrates the upper surface and the lower surface, and the support table 110 is cut into a first partition 111 and the second. Division 112, the continuous seam 120 extends in the direction of the m axis, and through the opposite sides of the support table 110, the M axis parallel to the upper surface.

[0077] The upper s...

Embodiment 2

[0090] A pilot device comprising an operational platform in Example 1, and a first pushing machine and a second piler.

[0091] The first pile driver will be described below.

[0092] See Figure 7 - Figure 12 In the present application, the axial direction refers to the extending direction of the axis, for example, the first axis direction refers to the extended direction of the first axis, and the second axis direction refers to the extended direction of the second axis, and is pushed.

[0093] The first pile driver is used to unplug the H steel pile, which includes a support frame 60 including a rectangular force frame 61 and a support plate mounted at the bottom of the force frame 61. 62. The top of the force frame 60 is open, and a steel pile aisle 65 for use in the h-steel pile 800 is formed on the support plate 62; two first first in the inner cavity 63 of the support frame 60; The clip pile jack 70, the two first clip pile jack 70 is located on both sides of the steel pile ...

Embodiment 3

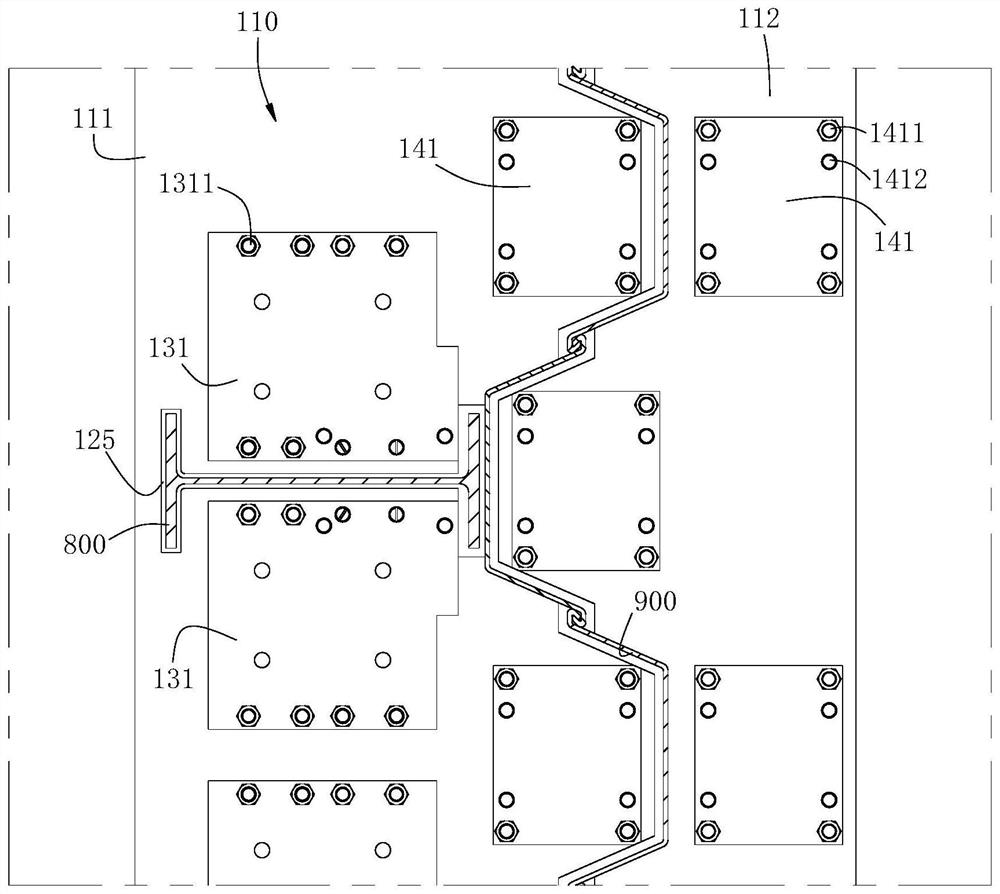

[0120] A method for extraction of a combination of steel sheet piles, piles using pulling apparatus embodiment is performed, comprising the steps of:

[0121] (1) recovering steel pile H:

[0122] See Figure 1 - Figure 17 Firstly the first pile drivers supported on the platform, the first lift jack on each side of the web of the H steel piles, steel piles and H is inserted into the channel steel piles, a steel pile above the ground in H the body defines an end portion of the pile hole.

[0123] Adjusting the first lift jack A second extension length of the piston rod, the inner and outer Pile Holes Pile Holes and Piles body facing, with pin holes through the outer pull the pile, the pile body and the inner hole Pile Holes the steel piles H hanging on the lifting member and the second elongate rod a, H steel piles driven upwardly until the maximum elongation a second piston rod, after, removal of the pin, so that departing from the steel pile H lifting members.

[0124] A second pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com