Method and system for locating equipment fault sound source

A technology for sound source localization and equipment failure. It is applied in localization, neural learning methods, radio wave measurement systems, etc. It can solve problems such as being susceptible to interference, low positioning accuracy, and poor real-time performance, avoiding iterative calculations and suppressing environmental noise. Interfere, reduce the effect of real-time requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

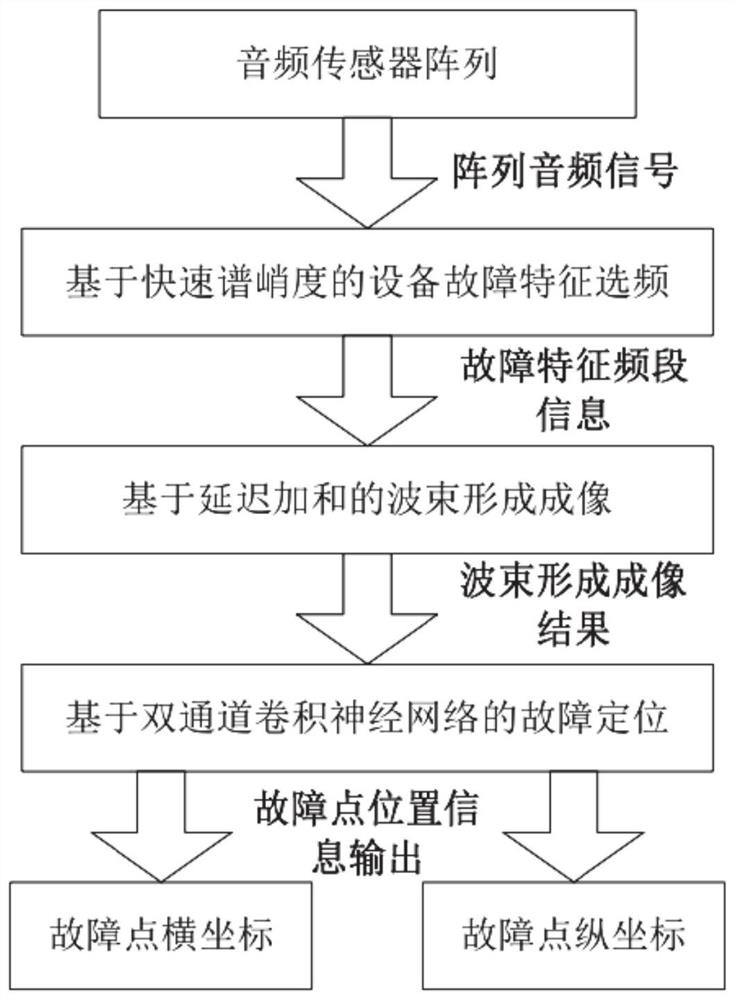

[0043] A sound source localization method for equipment faults based on fast spectral kurtosis beamforming and dual-channel convolutional neural network, such as figure 1 shown, including the following steps:

[0044] Step 1. Collect the audio signal of the device through the audio sensor array.

[0045]Through the audio sensor array, the audio signal during the operation of the equipment is collected. In order to facilitate the calculation of subsequent positioning results, the audio sensor array is usually arranged in a rectangular or square structure. During the training process, this signal is the sensor array audio signal of known multiple sound source positions. When actually locating the fault point of the equipment, this signal is the audio signal of the equipment collected by the sensor.

[0046] Step 2. Fault characteristic frequency selection based on fast spectral kurtosis algorithm.

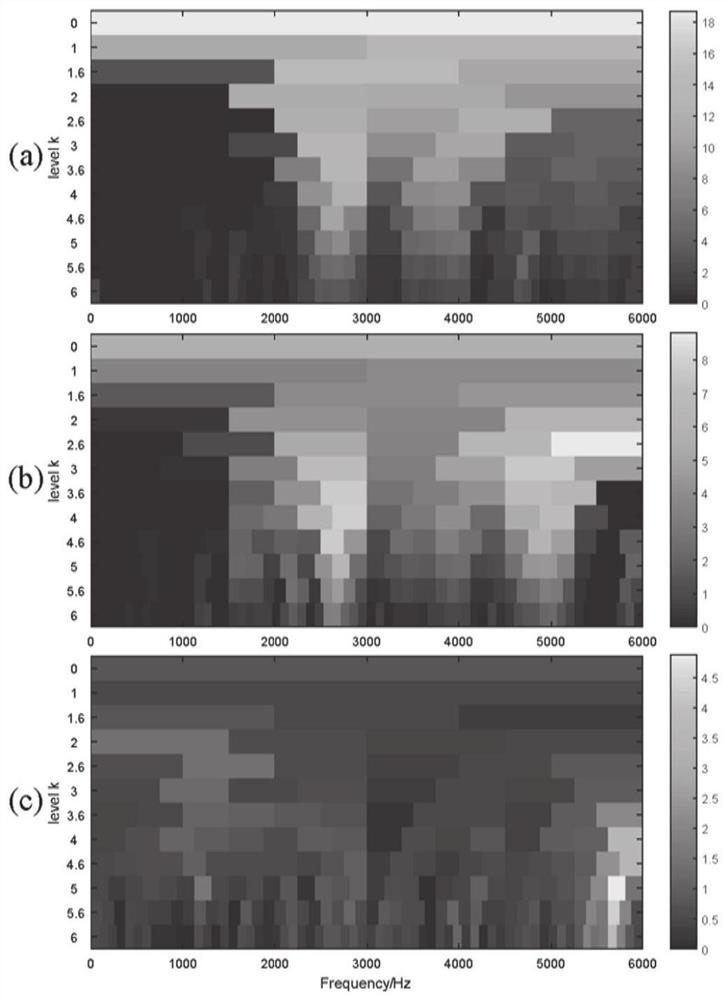

[0047] The specific steps of fault feature frequency selection based on fast...

Embodiment 2

[0094] A device fault sound source localization system, comprising:

[0095] an audio sensor array configured to collect audio signals during operation of the device;

[0096] The fault feature frequency selection module is configured to take the collected equipment sound signal as the signal to be analyzed, perform Fourier transform on the signal to be analyzed, calculate the fast spectral kurtosis index of the signal to be analyzed according to the transformation result, and determine according to the fast spectral kurtosis index Fault feature frequency selection results;

[0097] The beamforming imaging module is configured to calculate a cross-spectrum matrix and a delay sum steering response according to the frequency selection result of the fault feature and the signal to be analyzed, and obtain the delay sum beamforming imaging result of the fault frequency selection;

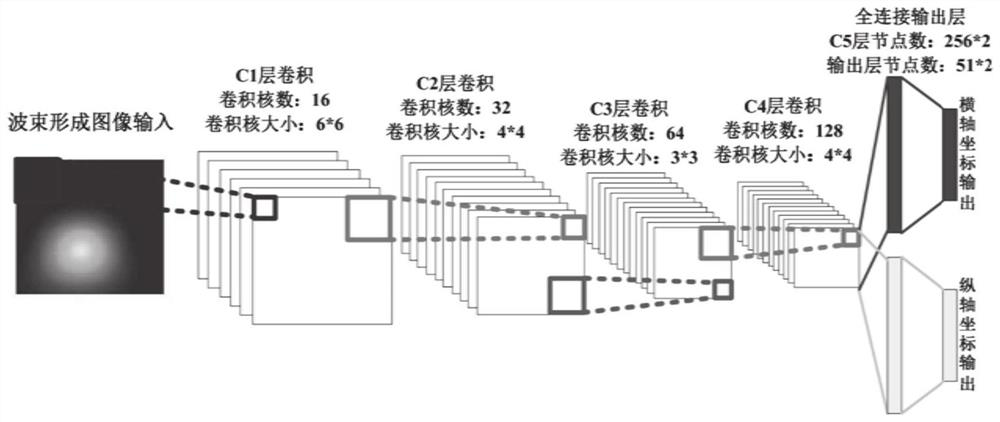

[0098] The sound source location module is configured to input the delay-sum beamforming imaging res...

Embodiment 3

[0100] A computer-readable storage medium, in which a plurality of instructions are stored, and the instructions are suitable for being loaded by a processor of a terminal device and executing the above-mentioned method for locating a sound source of a device failure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com