Reentry and reexit path planning method for automatic container wharf AGV with time window

A container and time window technology, applied in the field of AGV re-entry and re-exit path planning in automated container terminals, can solve problems such as low AGV utilization and affecting the efficiency of terminal transportation links.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0095] Before describing the method of the present invention, first introduce the AGV re-entry and re-exit model with a time window.

[0096] In the actual dispatching of the port, because the containers on the ship are of different weights, in order to ensure the stability of the transportation during transportation, the heavier containers will be placed at the bottom and the lighter containers will be placed at the top.

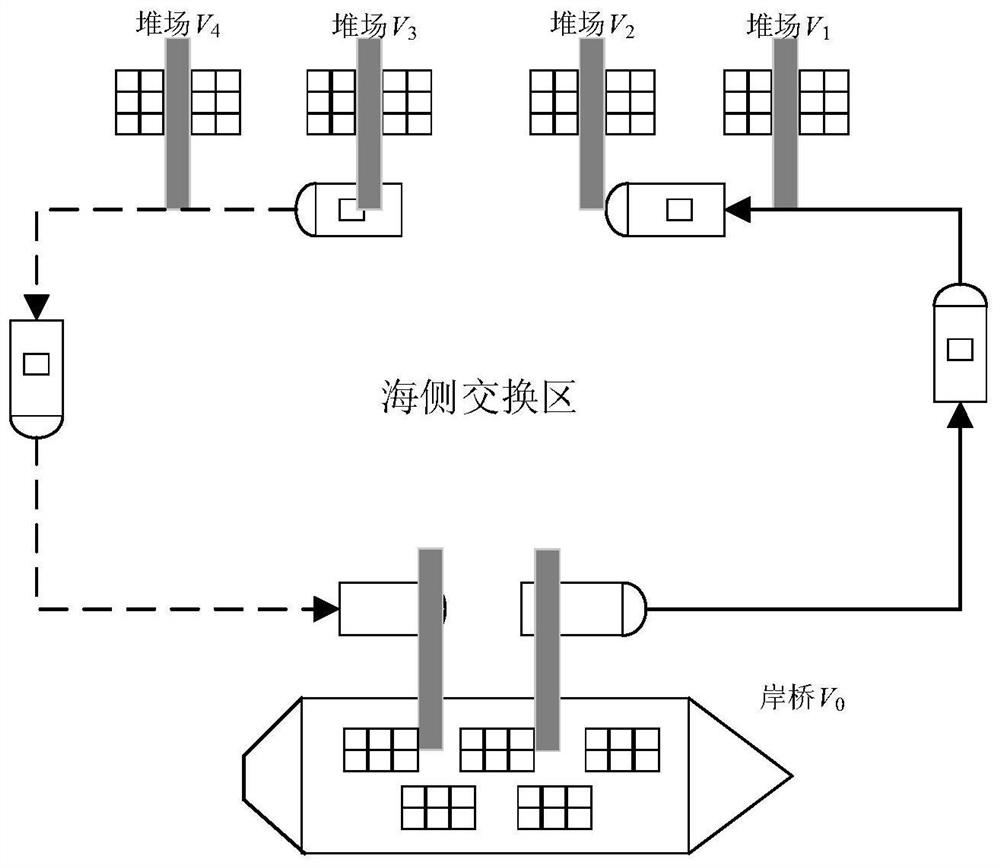

[0097] Therefore, in actual situations, containers will have a loading and unloading sequence. The method of the present invention uses the time window to describe the sequence of loading and unloading of each container, and the re-entry and re-exit scheduling scenario based on the time window is as follows: figure 2 shown.

[0098] Suppose the number of cargo ships is one, there are multiple AGVs, and there are multiple containers to be carried. Each AGV carries one container at a time. The container needs to be transported from the terminal to the yard ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com