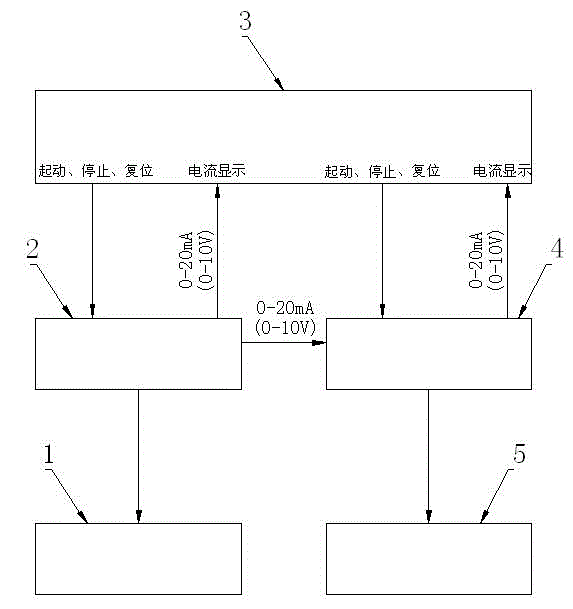

Automatic control system with double frequency converters

An automatic control system, dual frequency converter technology, applied in the direction of electrical program control, program control in sequence/logic controllers, etc., can solve the impact of equipment loss and utilization, equipment does not meet production requirements, motor or mechanical parts Damage and other problems, to achieve the effect of low equipment and production costs, saving production costs and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

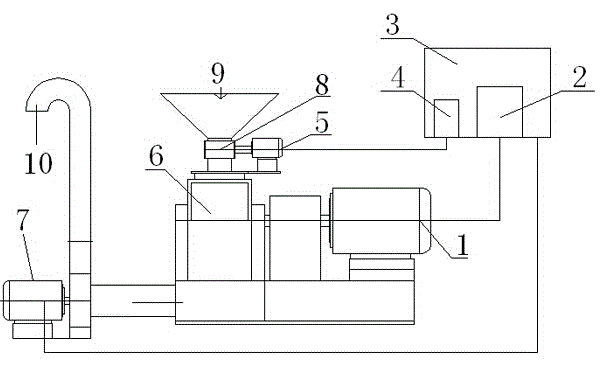

[0014] as attached figure 2 As shown, a pulverizer with an automatic control system with double frequency converters consists of a main machine motor 1, a main machine frequency converter 2, a control display table 3, a feeder frequency converter 4, a feeder motor 5, a pulverizer 6, and a fan 7 , feeder 8, feed port 9, and discharge port 10; wherein: the host motor 1 is controlled by the host inverter 2, and the host motor 1 drives the pulverizer 6 to rotate; the feeder motor 5 is controlled by the feeder inverter 4 Control, the feeder motor 5 drives the feeder 8 to rotate; the control display table 3 is equipped with a host frequency converter 2 and a feeder frequency converter 4, which are respectively connected to the host motor 1, the feeder motor 5 and the fan 7, and the feeding The port 9 is arranged above the feeder 8, and the discharge port 10 is connected to one side of the fan 7.

[0015] The working principle of this embodiment: after the power supply of 220-380V ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com