A re-entry and re-exit path planning method for an automated container terminal AGV with a buffer zone for quay cranes

A buffer zone and container technology, applied in the field of AGV re-entry and re-exit path planning in automated container terminals, can solve problems such as waste of time resources, impact on transportation links, etc., and achieve the effects of improving efficiency, improving work efficiency, and eliminating constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

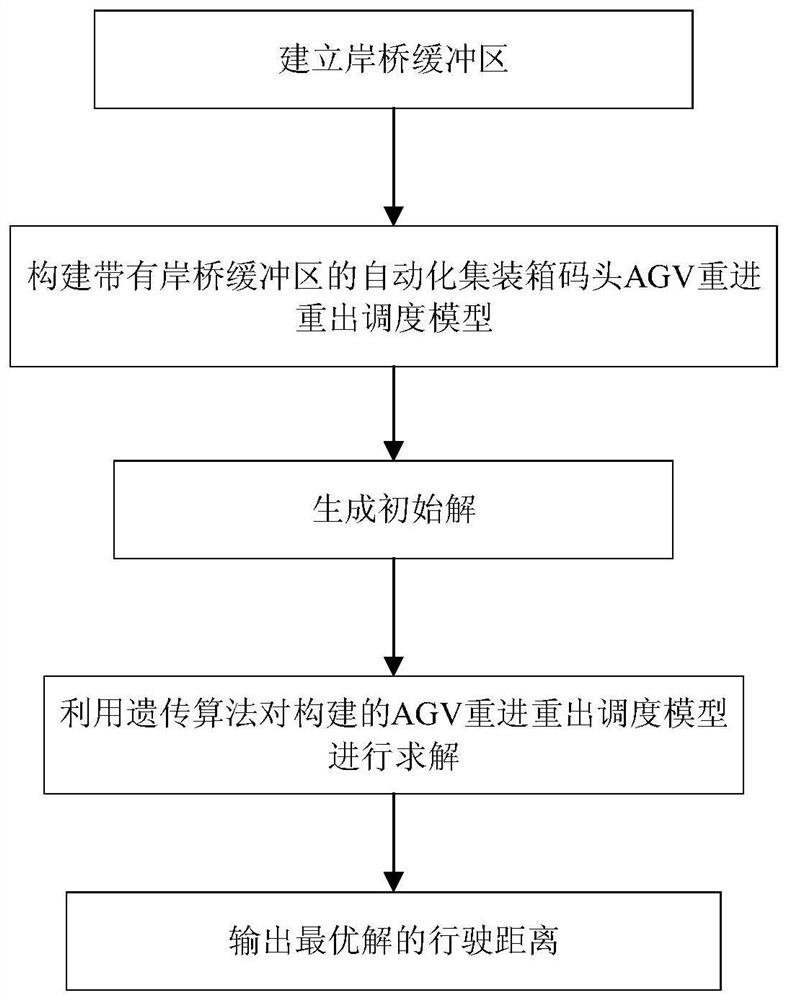

[0113] Such as figure 1 As shown, the first embodiment proposes an automated container terminal AGV with a shore bridge buffer, which is a path optimization method for re-re-re-re-reforming a single cargo vessel.

[0114] In the container terminal, the AGV task is to carry containers to the yard side from the shore bridge, uninstall the container back to the shore bridge, or carry the container carrier back the shore bridge after driving from the shore bridge.

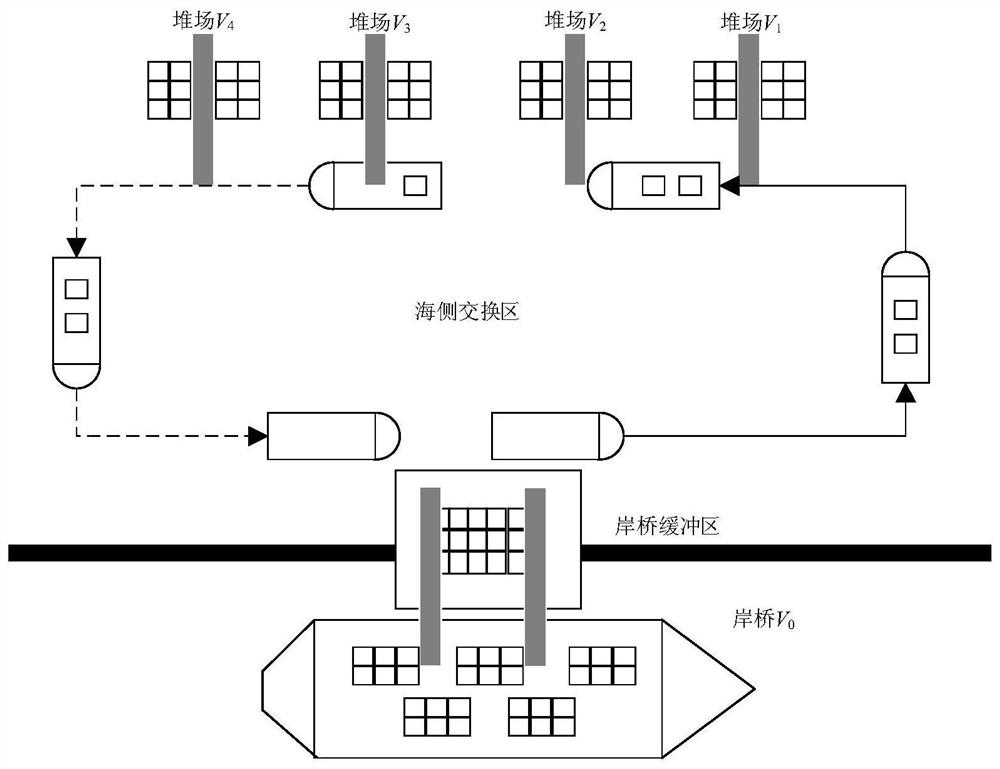

[0115]The re-retransmission mode proposed in this Example 1 refers to the addition of the container after the AGV is completed, and the two-way container carrying between the shore bridge and the yard, such as figure 2 Indicated.

[0116] The goal of the path optimization method of this embodiment is to complete all container transportation in the shortest distance, and the total distance of all AGV trains is shorter.

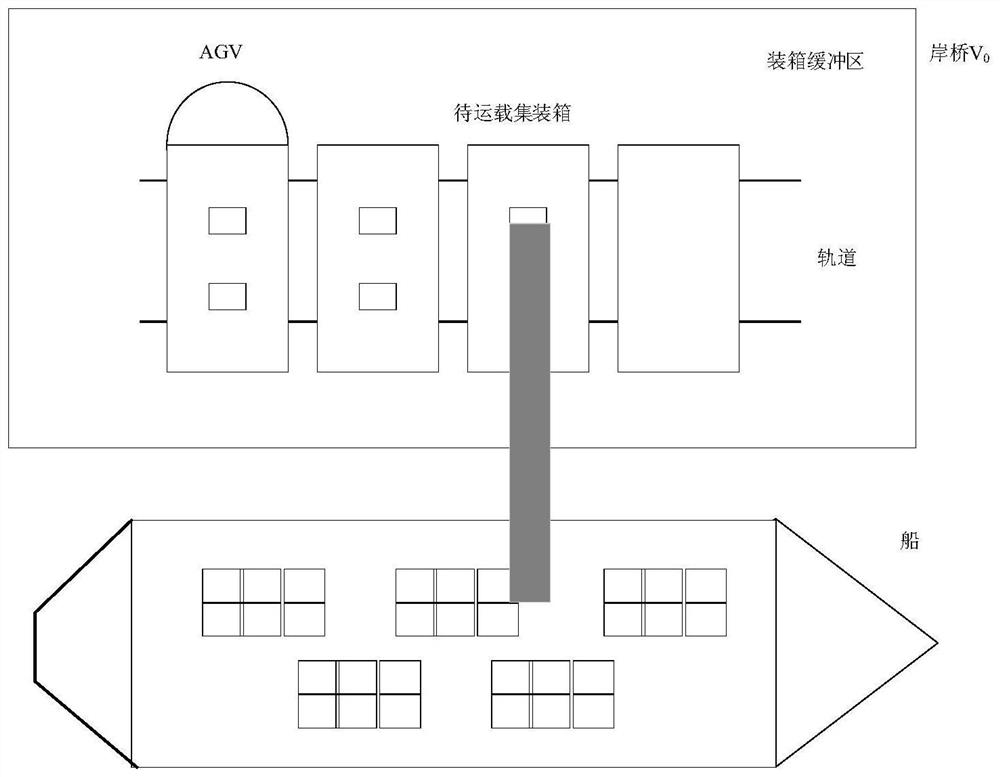

[0117] In this Example 1, by increasing the shore bridge buffer, facilitating the low coupling between t...

Embodiment 2

[0236] Such as Figure 5 As shown, the second embodiment also describes an automated container terminal AGV in-strait bridge buffer, which includes the following steps:

[0237] I. Create a shore bridge buffer that includes a box buffer and a unloading buffer.

[0238] II. Constructing an automated container terminal AGV with a shore bridge buffer Terminal AGV re-retransmission scheduling model.

[0239] III. Generate the initial solution, by screening the same task point in the process of generating the initial solution to reduce the mixed particle group algorithm to reduce the spatical space scale search for the mixed particle group algorithm.

[0240] IV. Solution of the automated container terminal AGV in the automated container terminal by mixed particle group algorithm.

[0241] It should be noted that the process of step I-III in this Example 2 is exactly the same as that of the first embodiment, and the present embodiment is no longer disclosed, and the solution process of ...

Embodiment 3

[0270] Such as Image 6 As shown, the third embodiment also describes an automated container terminal AGV re-feed returning path planning method with a shore bridge buffer, which includes the following steps:

[0271] I. Create a shore bridge buffer, including packing buffers, and unloading buffers.

[0272] II. Constructing an automated container terminal AGV with a shore bridge buffer Terminal AGV re-retransmission scheduling model.

[0273] Iii. To generate the same task point in the process of generating initial solutions to reduce the simulated annealing algorithm to reduce the solution space scale search for an annealing algorithm.

[0274] IV. Solving the Automated Container Terminal AGV Reburses the Solution of Automated Container Terminal.

[0275] It should be noted that the process of step I-III in the present embodiment is exactly the same as that of the first embodiment, and the present embodiment is no longer disclosed, and the solution process of the annealing algori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com