Fully automatic low headroom segment transporter and segment transport method based on binocular vision technology

A binocular vision and fully automatic technology, which is applied in earthwork drilling, shaft equipment, shaft lining, etc., can solve the problem that the main part of the transporter cannot be arranged on the same plane as the track mechanism, and cannot adapt to the industry trend of shield machine miniaturization, It is not suitable for problems such as low headroom operation occasions, so as to achieve the effect of realizing automatic operation, avoiding safety accidents and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

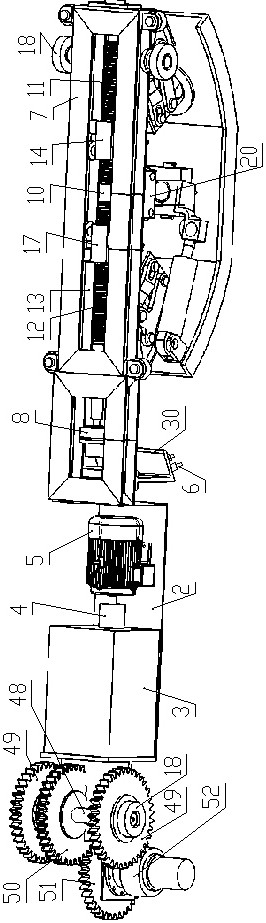

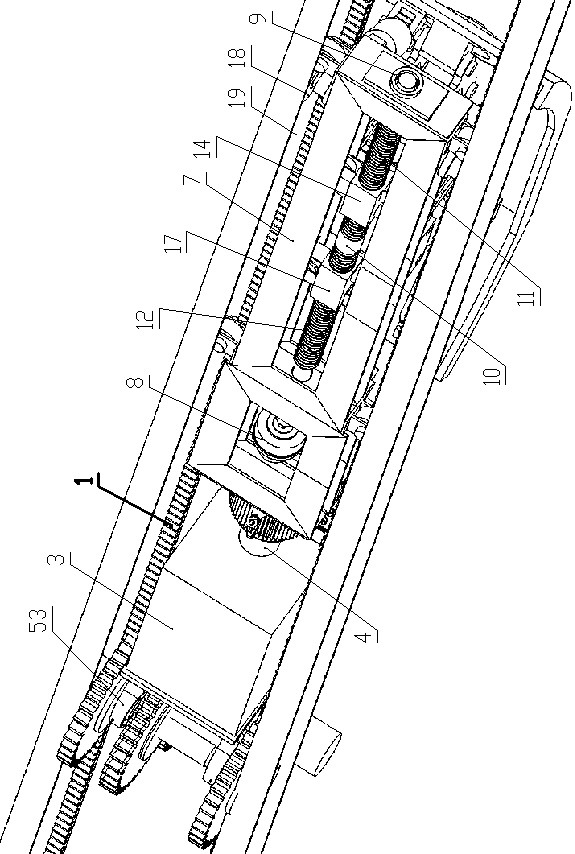

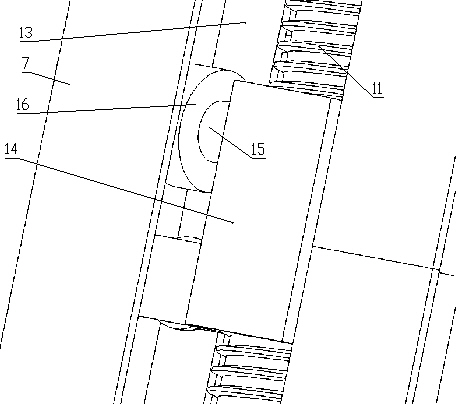

[0083] Such as Figure 1 to Figure 12 As shown, the fully automatic low-clearance segment conveyor based on binocular vision technology of the present invention is used in conjunction with the track arranged on the top of the constructed tunnel, and the track includes two racks 1 arranged parallel and side by side along the length of the tunnel; In the present invention, the width direction of the tunnel is the width direction, and the length direction of the tunnel is the front-rear direction.

[0084] It includes a traveling mechanism, a segment pick-and-place mechanism and a power mechanism for providing power for the travel mechanism and the segment pick-and-place mechanism. The power mechanism includes a fixed plate 2, and a hydraulic tank 3 is installed on the fixed plate 2, and the hydraulic tank 3 is connected to a A hydraulic pump 4 is provided, and the hydraulic pump 4 is connected with an electric motor 5 for driving the hydraulic pump 4, and the electric motor 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com