Swing rod position calibration device, error elimination method thereof and shift-by-wire actuator

A calibration device and slide bar technology, applied in the direction of transmission control, toothed components, belts/chains/gears, etc., can solve problems such as front and rear interference jamming, motor stall, function failure, etc., to eliminate motion errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

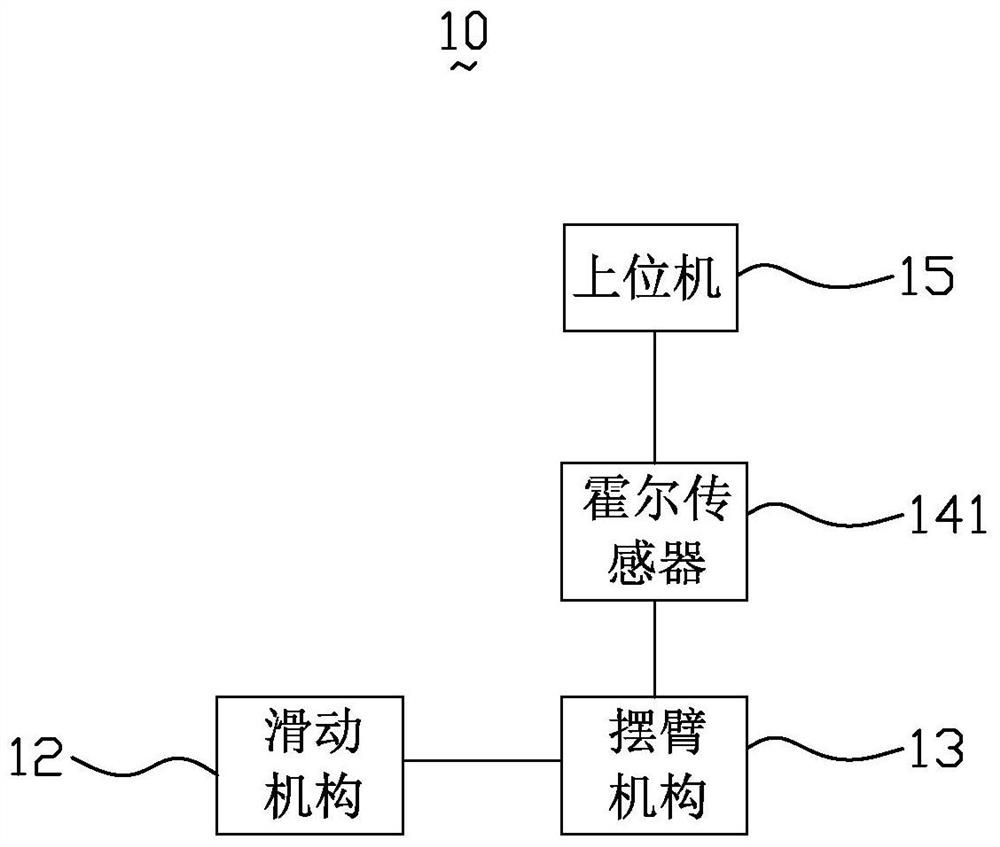

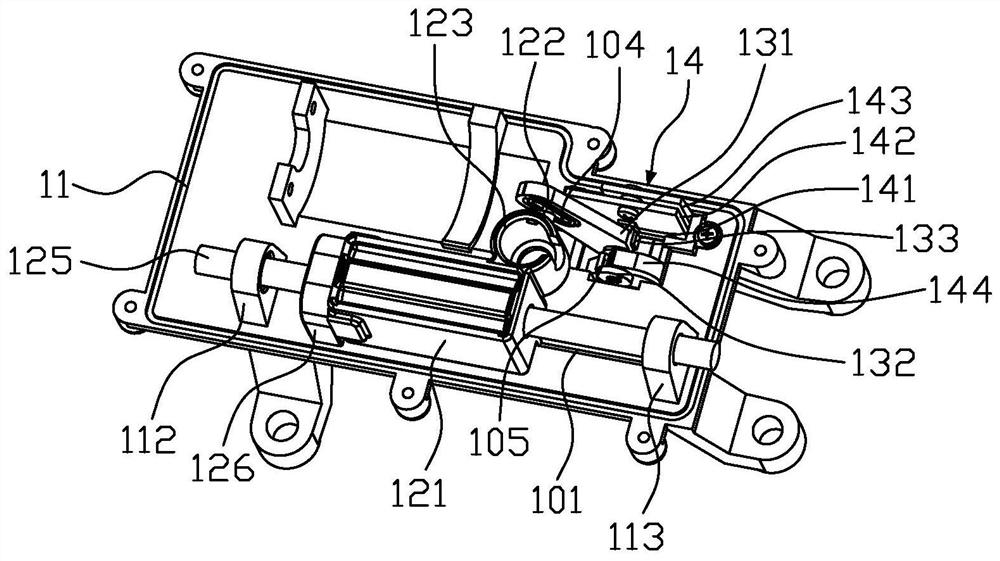

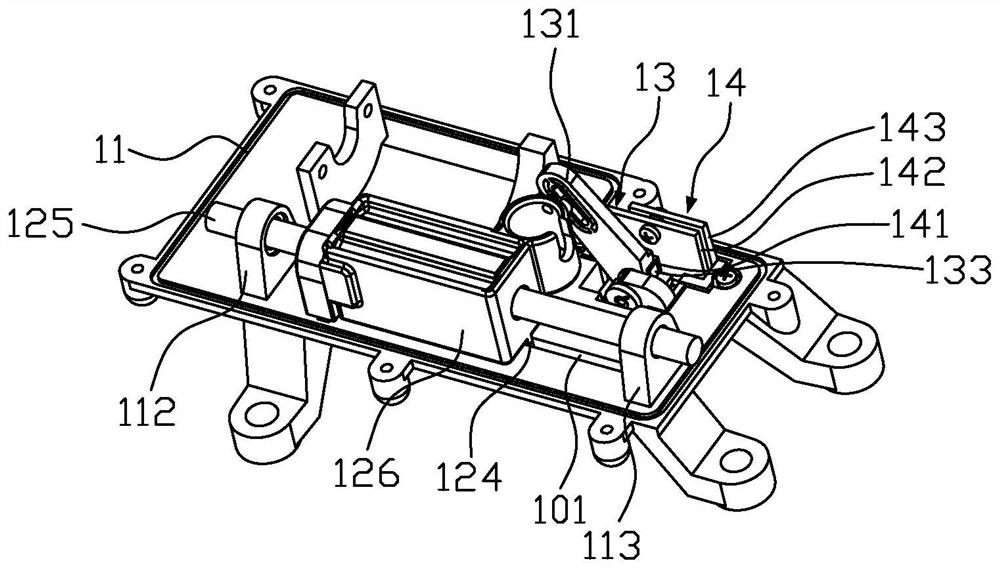

[0030] figure 1 is a schematic diagram of the pendulum position calibration device of the present invention, figure 2 is a partial structural schematic diagram of the pendulum position calibration device of the present invention, image 3 yes figure 2 The structural schematic diagram of the other direction of the pendulum position calibration device shown, Figure 4 yes figure 2 The schematic diagram of the side view structure of the pendulum position calibration device shown, Figure 5 It is a partial cross-sectional schematic diagram of the pendulum position calibration device of the present invention, please refer to Figure 1 to Figure 5 , The swing rod position calibration device 10 includes a frame 11 , a slide mechanism 12 , a swing arm mechanism 13 , a detection mechanism 14 and a host computer 15 .

[0031] The sliding mechanism 12 comprises a slide block 121, a slide bar 125 and a stop block 126, the slide bar 125 is arranged on the frame 11, the slide block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com