Device and method for multi-degree-of-freedom detection of workbench motion error

A technology of motion error and degrees of freedom, applied in the field of multi-degree-of-freedom detection devices for workbenches, can solve problems such as difficulty in achieving high precision, high installation requirements, complex structure, etc., to improve measurement accuracy and manufacturing accuracy, meet measurement requirements, Avoid feedback effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the implementation examples described here are only for illustration and explanation of the present invention, and are not intended to limit this invention.

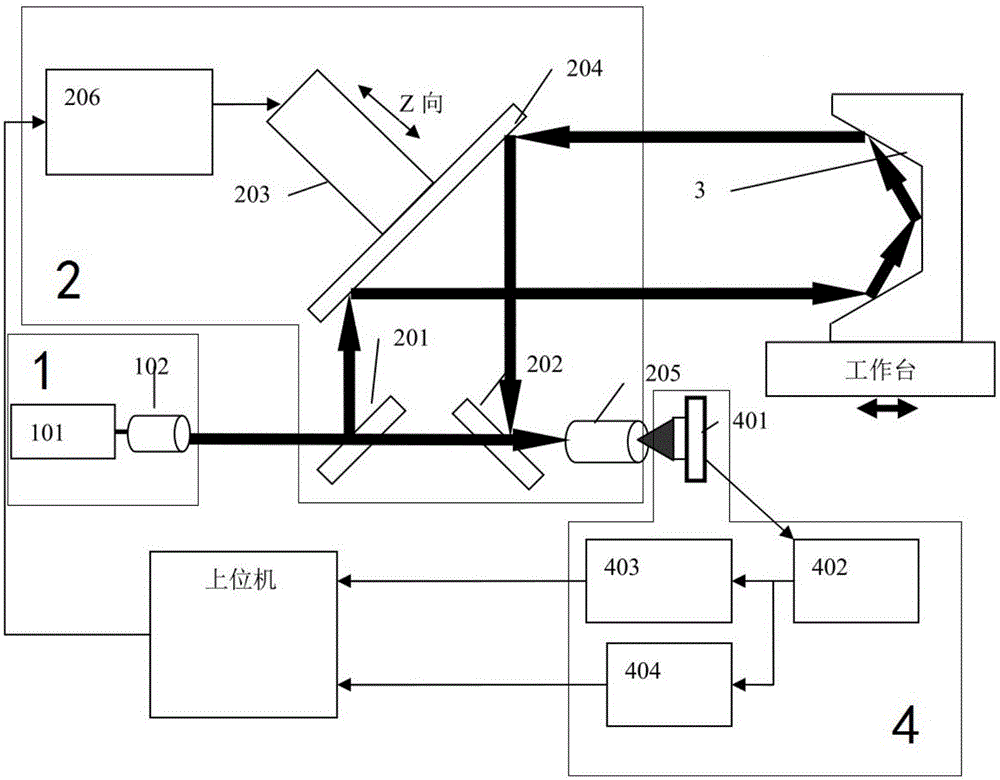

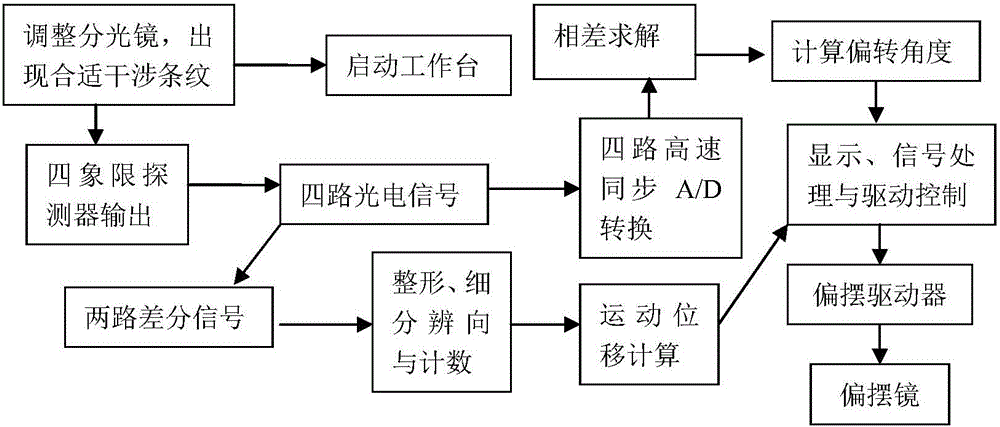

[0030] please see figure 1 , the technical solution adopted by the device of the present invention is: a device for multi-degree-of-freedom detection of workbench motion error, which is controlled by a host computer; includes a laser light source unit 1, a laser light path direction adjustment and interference modulation unit 2, and a three-sided mirror measurement The target surface unit 3 and the photoelectric receiving and converting unit 4; the laser light source unit 1 includes a high frequency stable laser 101 and a beam expander collimator 102, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com