Patents

Literature

52results about How to "Constant effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ophthalmologic irrigation solutions and method

InactiveUS20040072809A1Good curative effectEliminate side effectsBiocideSenses disorderPupilMydriasis

Solutions for perioperative intraocular application by continuous irrigation during ophthalmologic procedures are provided. These solutions include multiple agents that act to inhibit inflammation, inhibit pain, effect mydriasis (dilation of the pupil), and / or decrease intraocular pressure, wherein the multiple agents are selected to target multiple molecular targets to achieve multiple differing physiologic functions, and are included in dilute concentrations in a balanced salt solution carrier.

Owner:OMEROS CORP

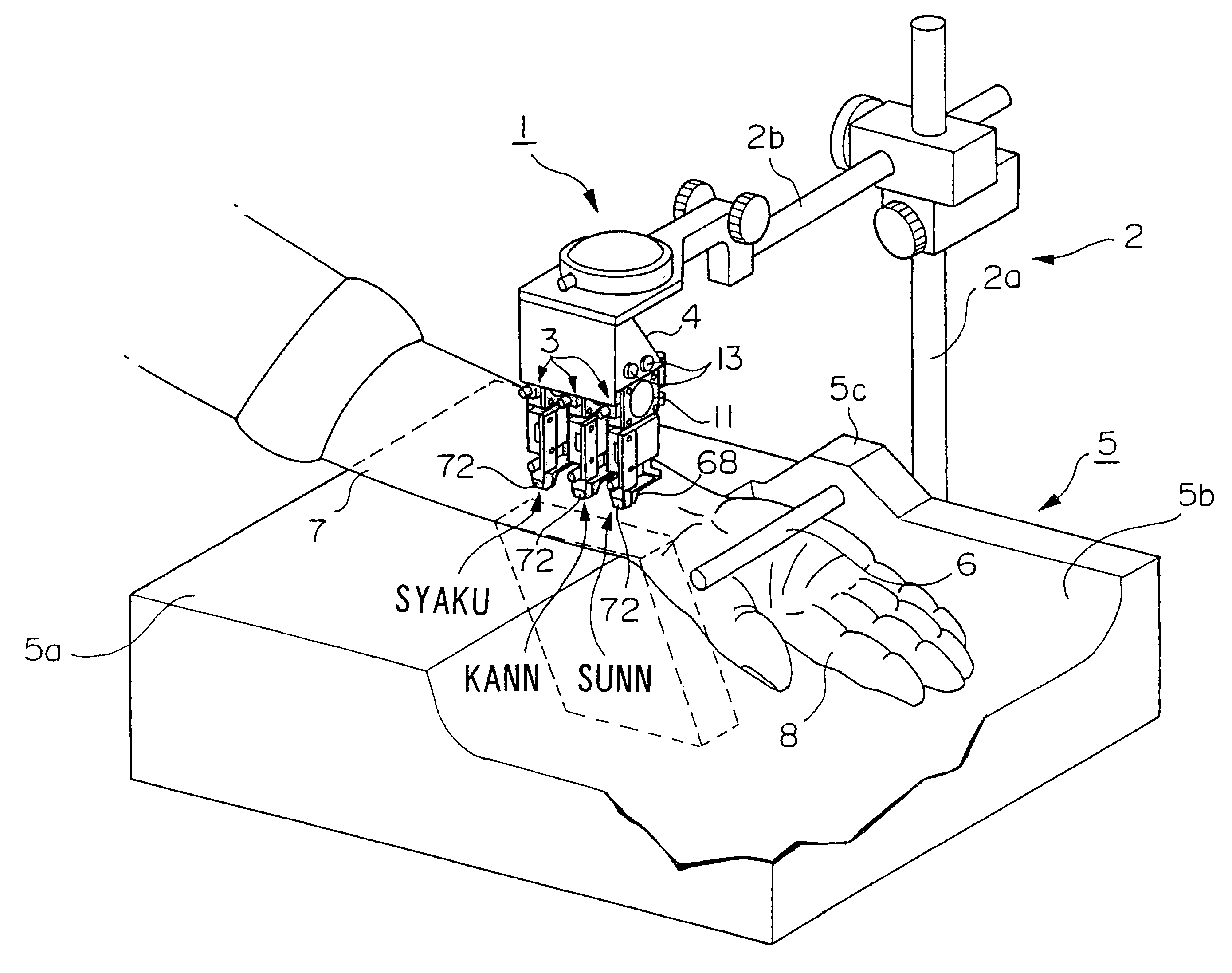

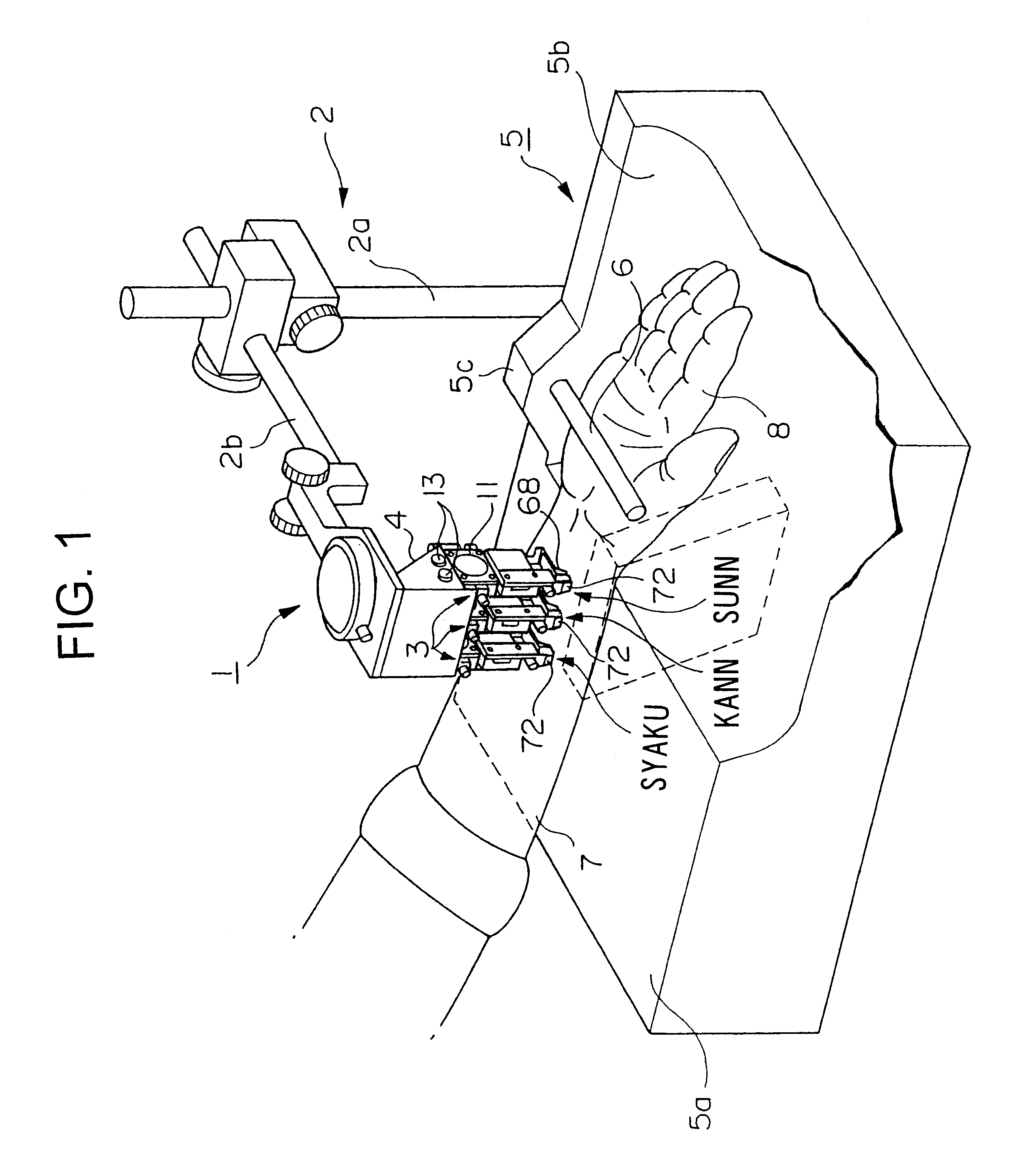

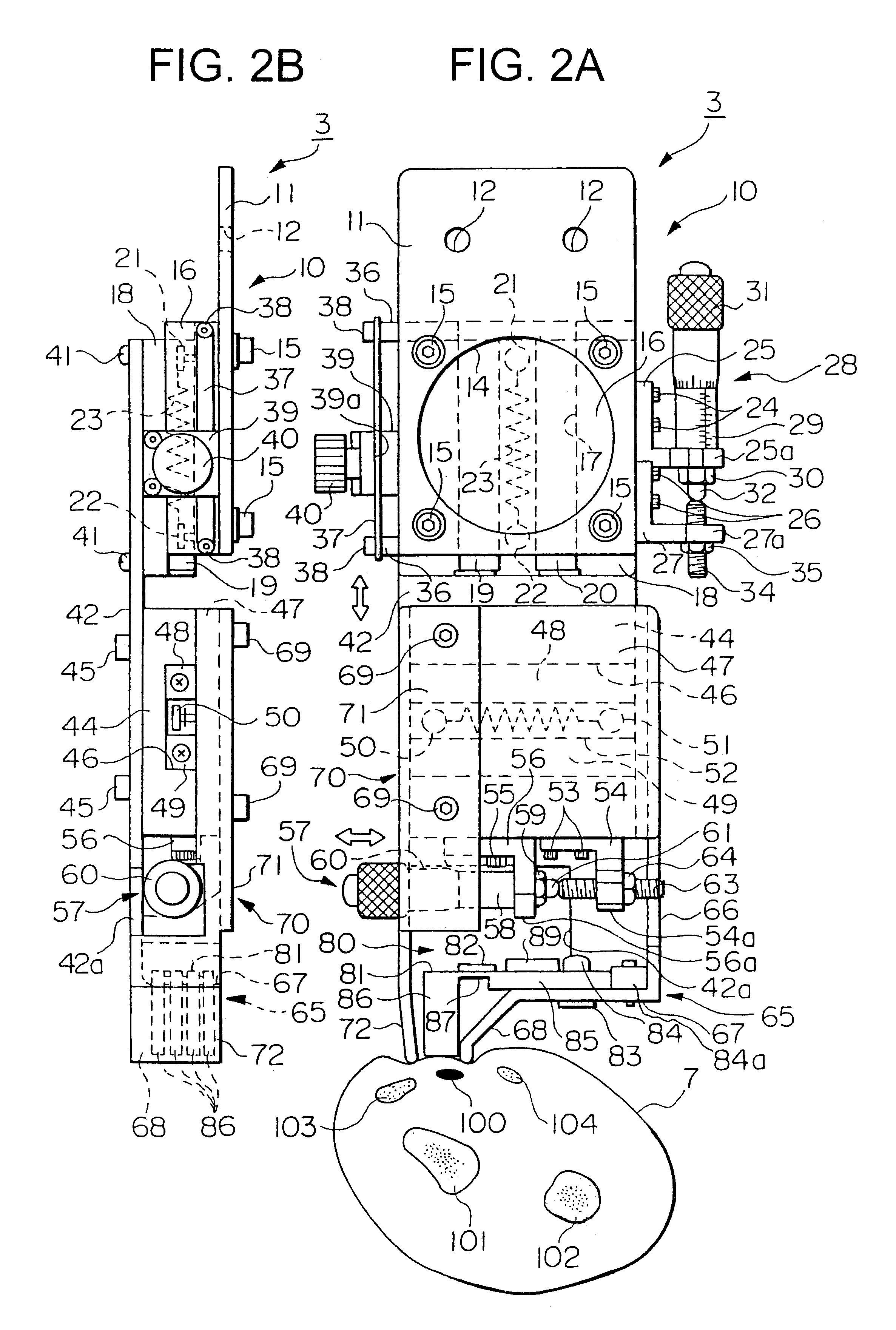

Blood pulse measuring device, pulsation measuring device, and pressure measuring device

A pulse wave measuring device is provided with a plurality of pulse wave measuring units. Each pulse wave measuring unit has a supporting member to which a beam of a pressure measuring device is attached. Contact portions at the distal end of the beam is in contact with the patient's arm, so that piezoelectric elements mounted on the beam measures the stress variation according to pulsation of the patient's radial artery. The supporting member has two pressing legs between which the contact portions of the beam are situated. The distal ends of the pressing legs are also pressed against the patient's arm. The pressing legs are harder than the radial artery. The interval between the pressing legs can be altered by handling a micrometer head. The contact portions are situated back from the distal ends of the pressing legs.

Owner:SEIKO EPSON CORP

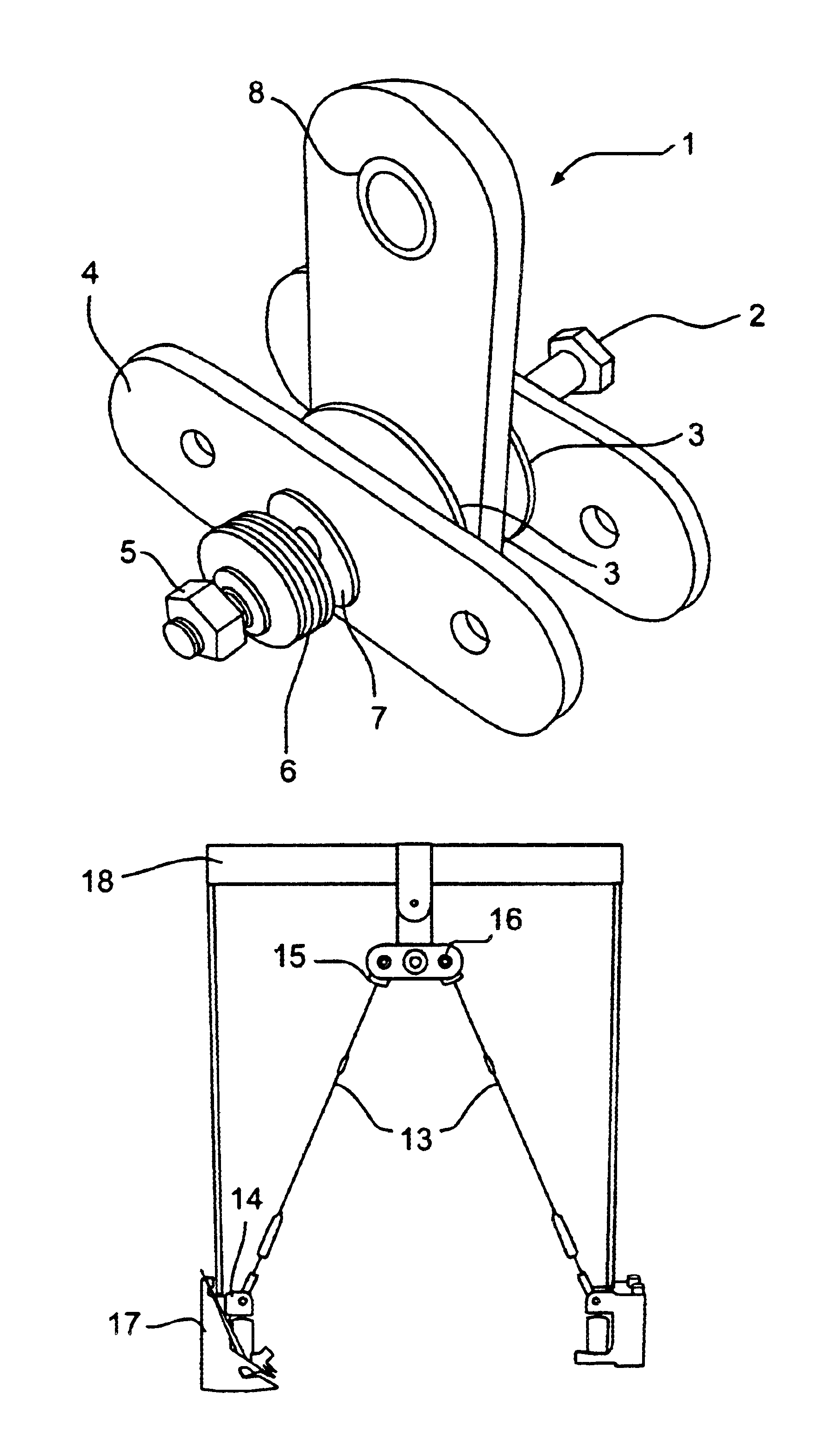

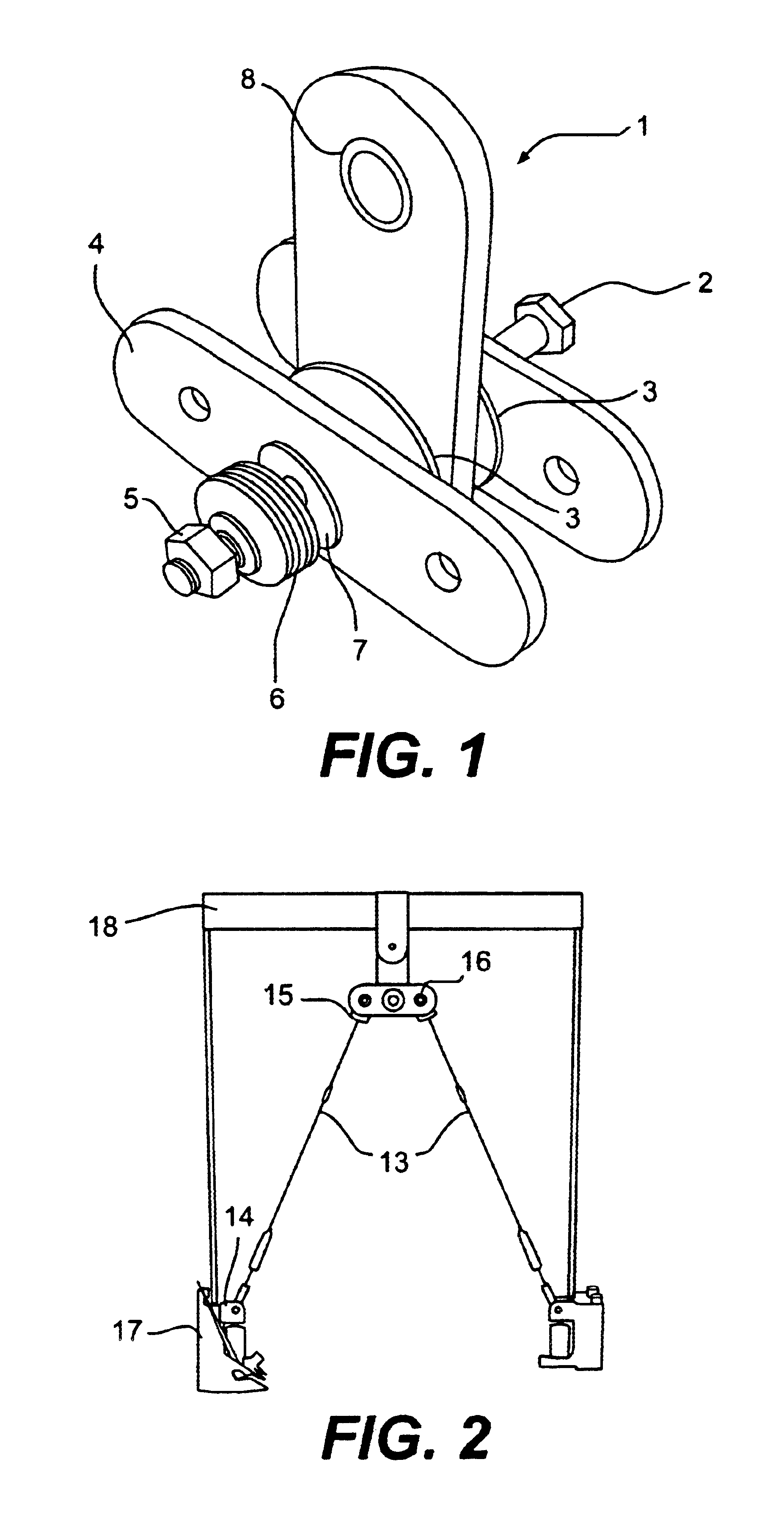

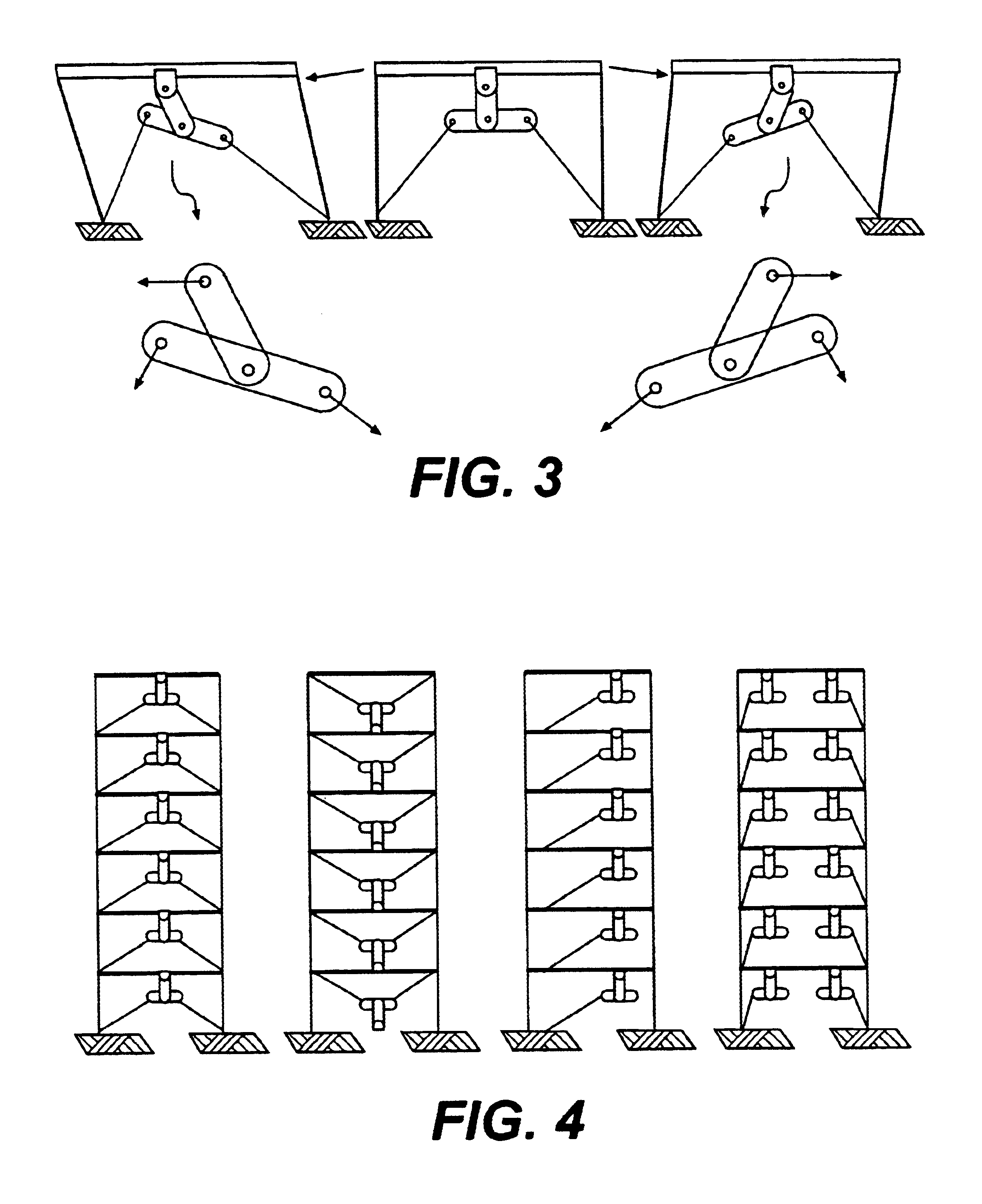

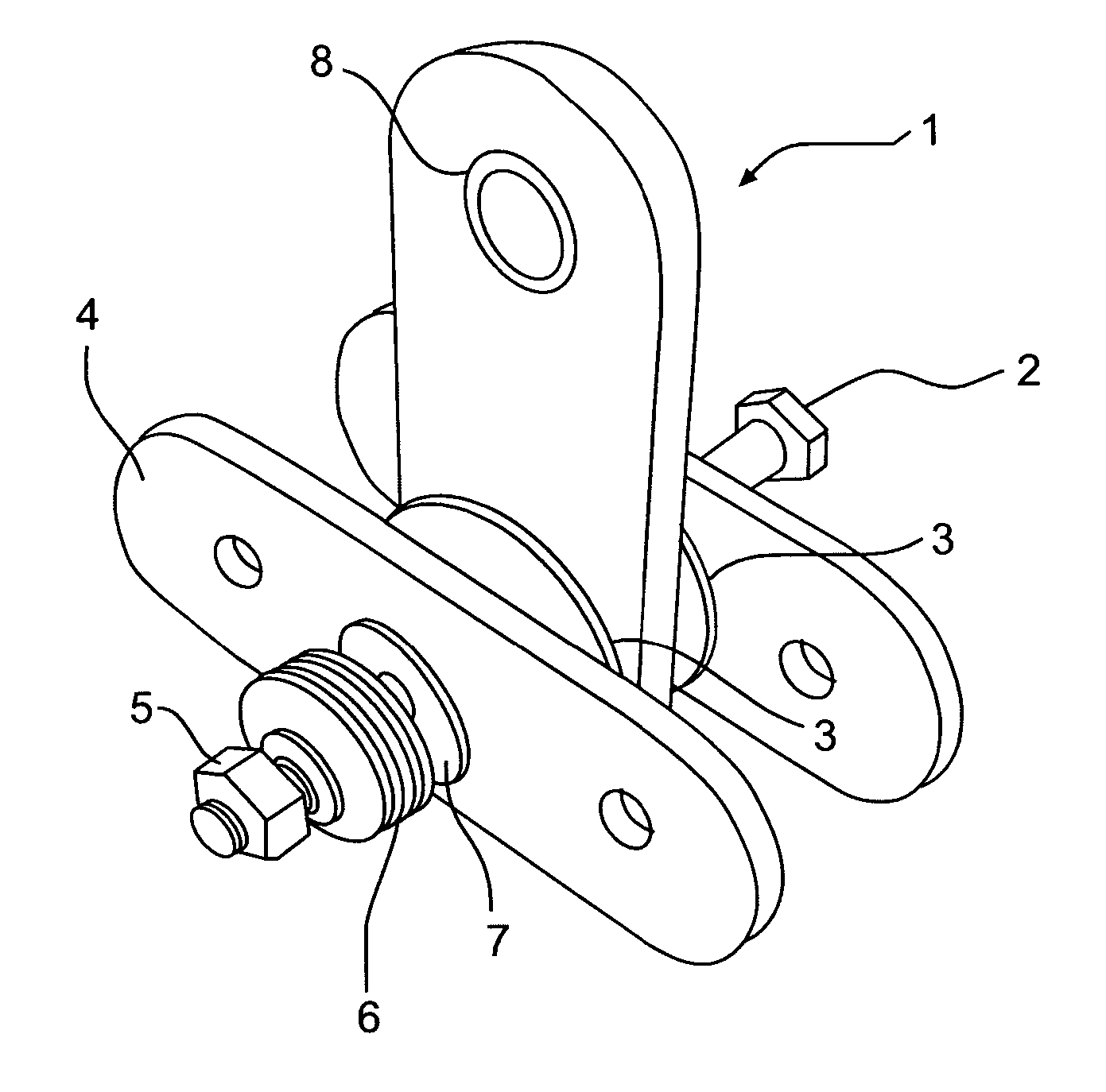

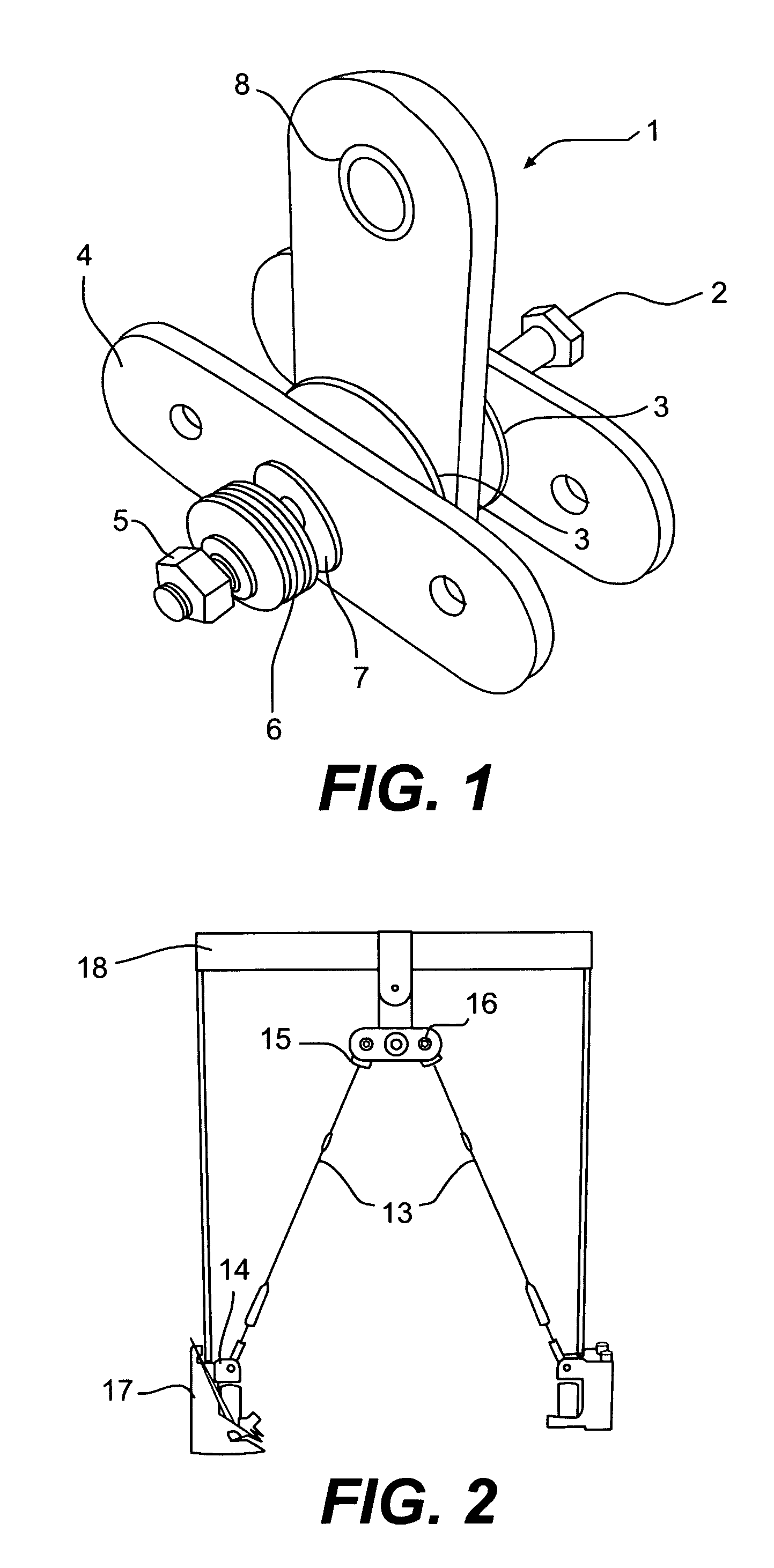

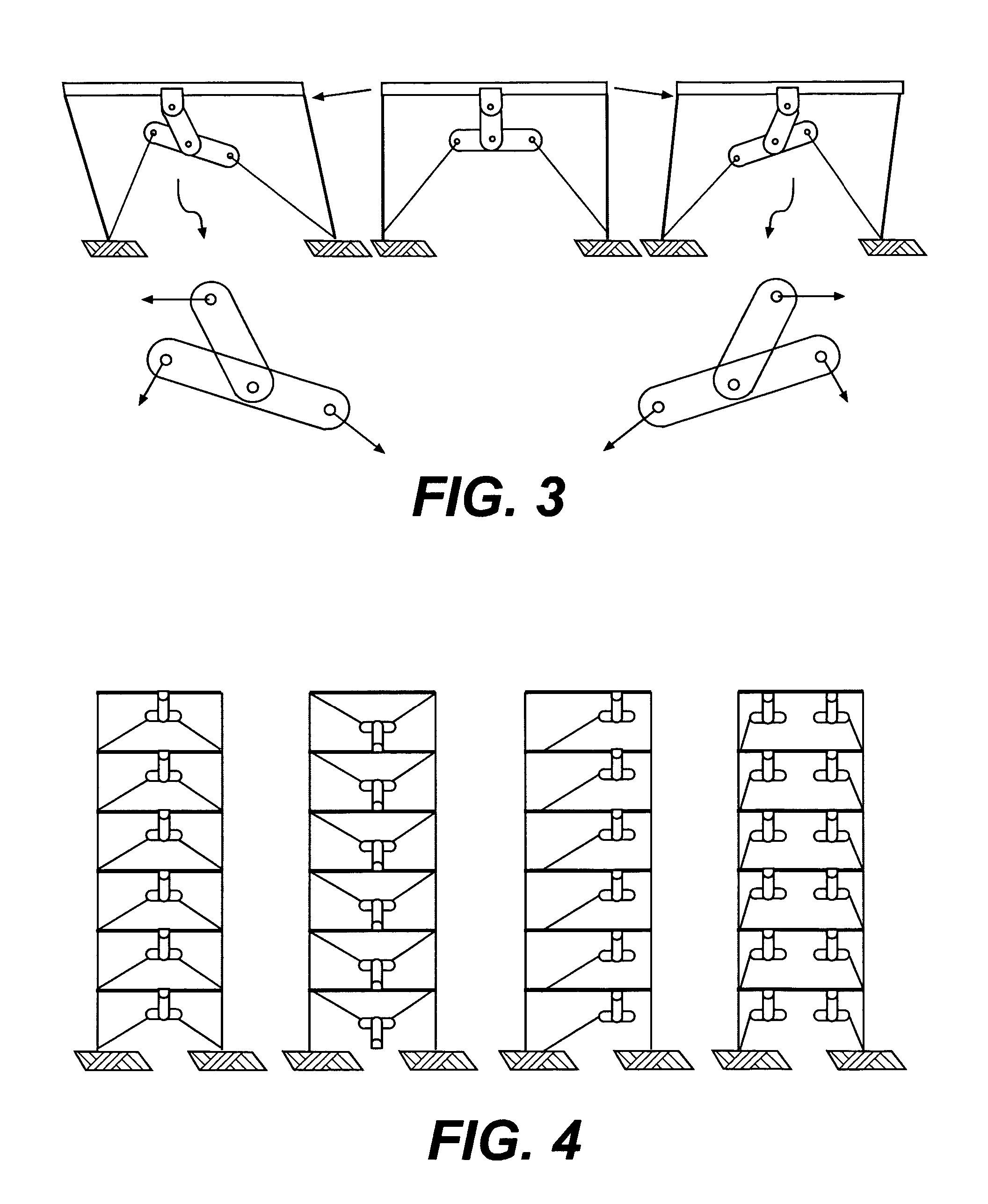

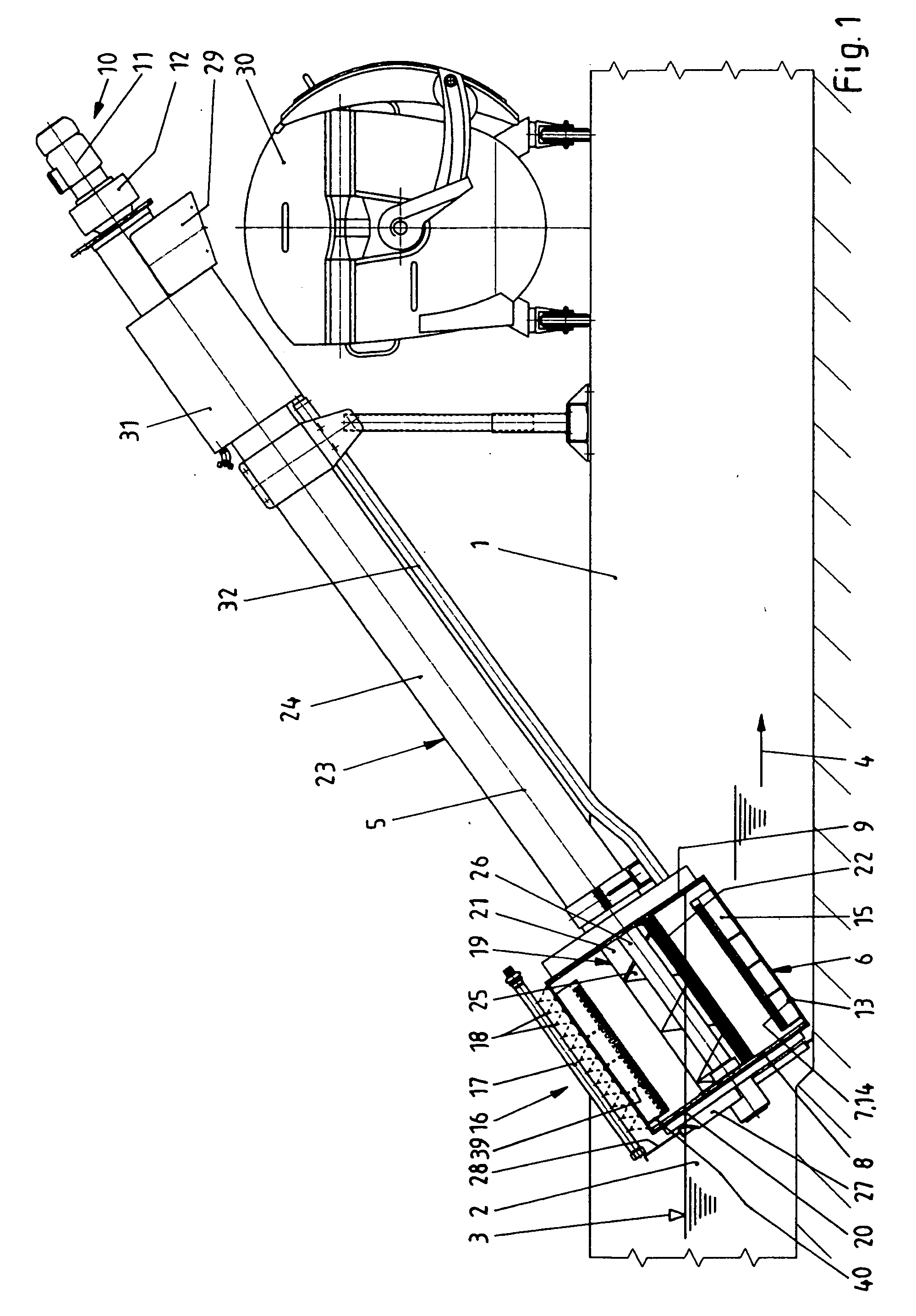

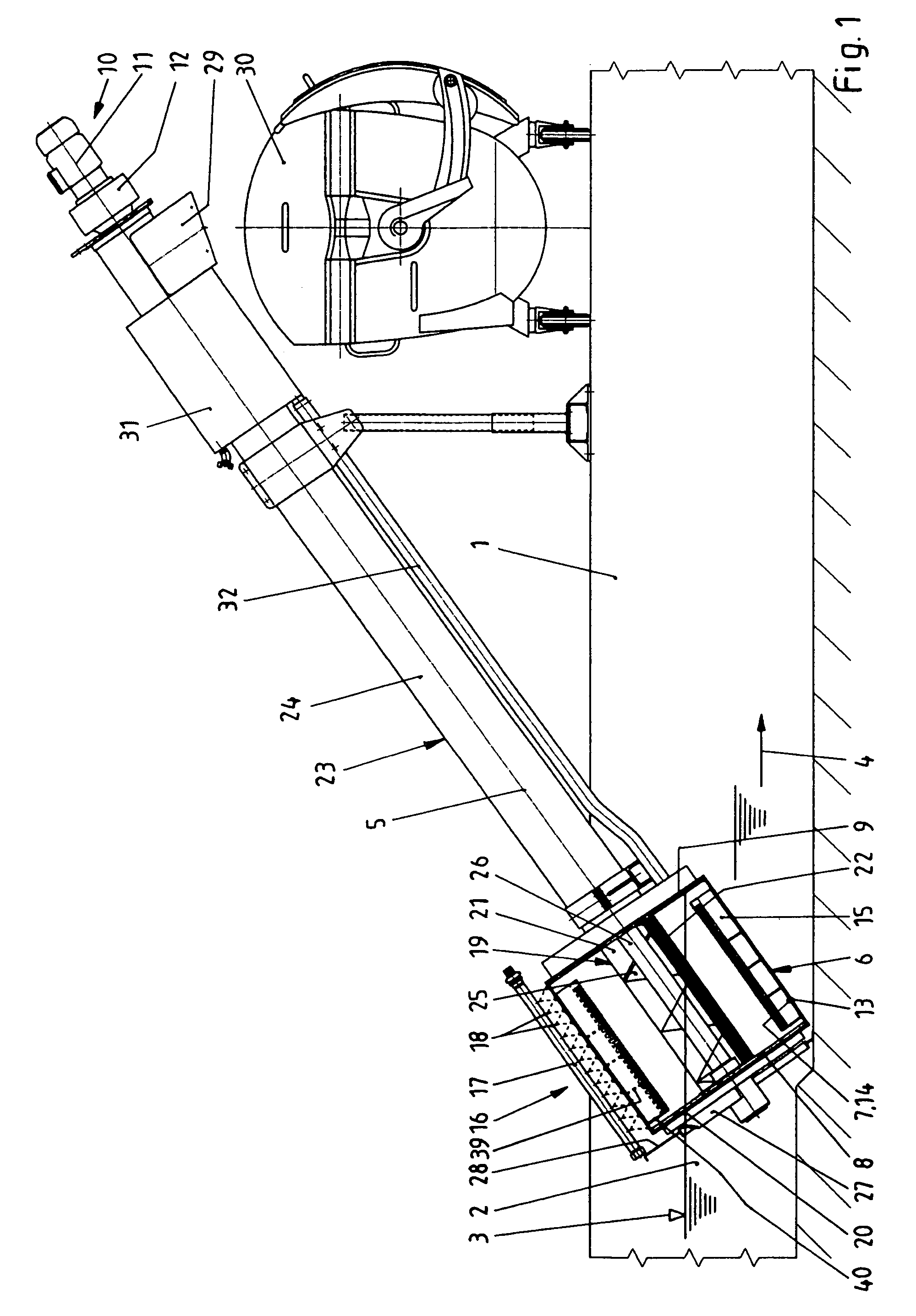

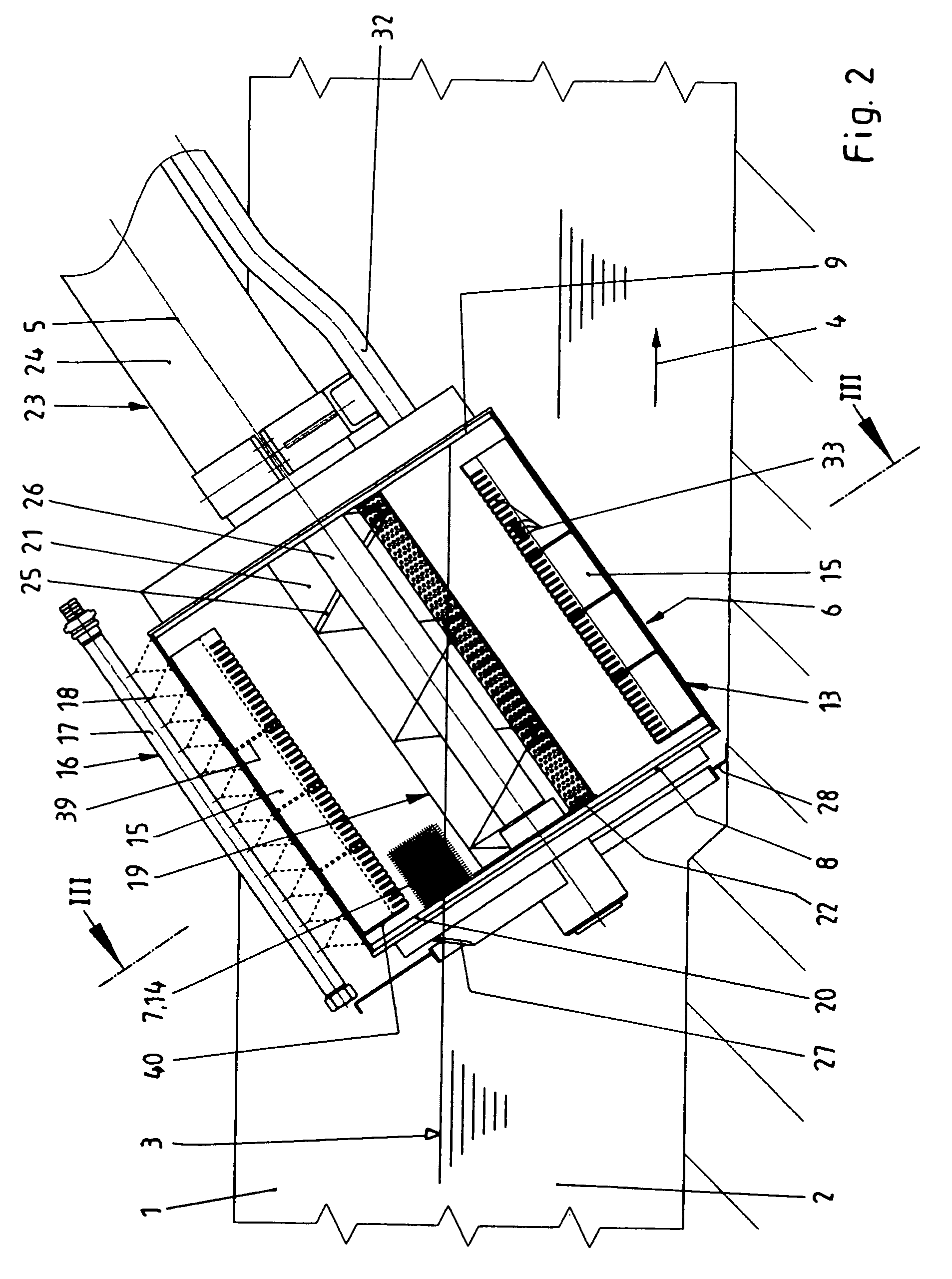

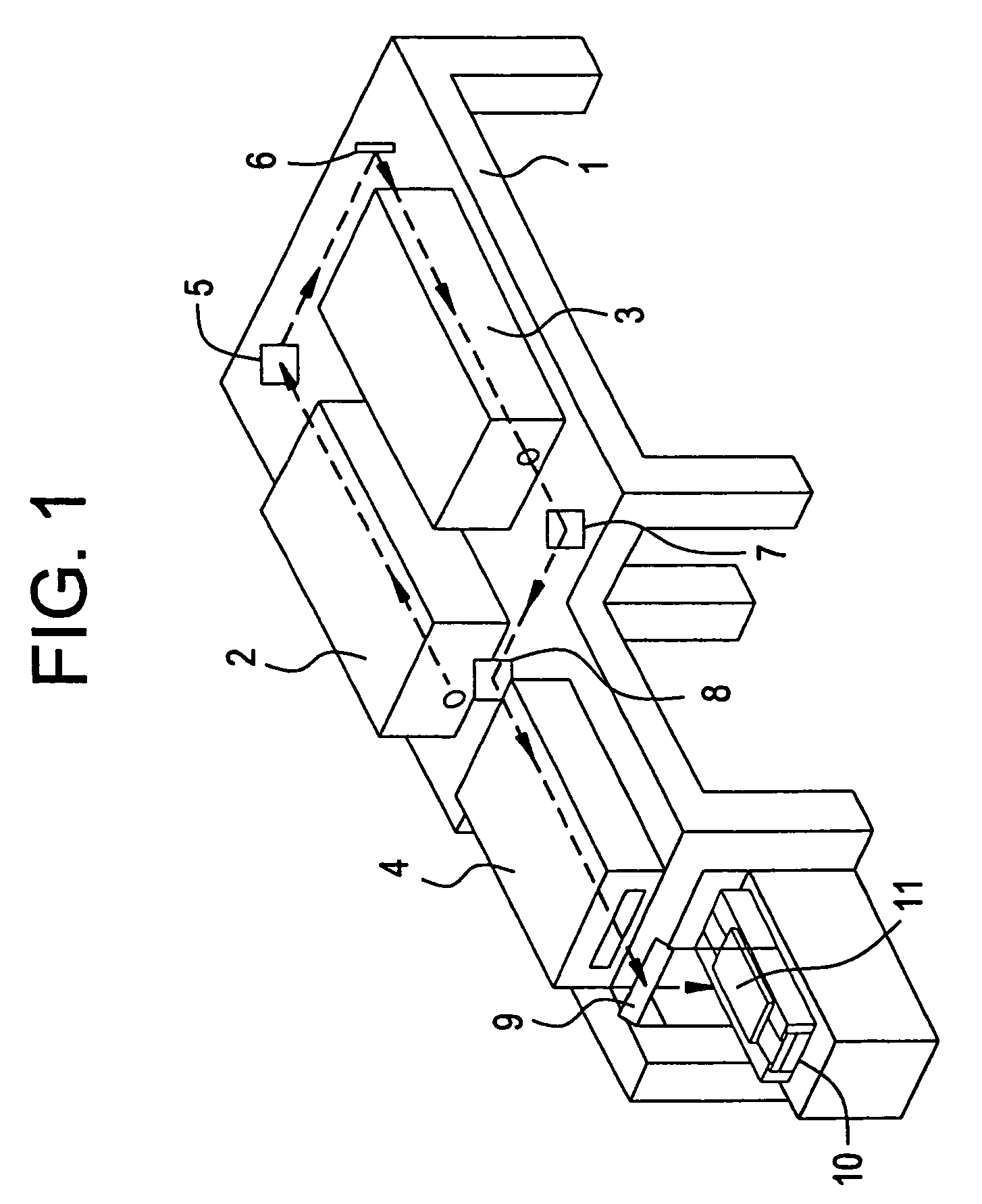

Device for damping movements of structural elements and a bracing system

InactiveUS6840016B1Constant damping effectPrice efficient and reliableProtective buildings/sheltersShock absorbersStructural systemStructural element

The invention relates to the protection of structural systems such as apartment houses against dynamic loading caused by earthquakes, wind, traffic etc. When a frame structure is excited by a horizontal external force, the girders starts to displace horizontally. If such displacements are large or if they occur periodically they may have serious impact on the conditions of the structure and may cause severe damages or even result in a collapse. The present invention relates to a very simply designed and easily produced damper with two members being interconnected in a rotational joint. By means of the arrangement of the damper in the structural system, displacement occurring in the system is transferred to the members being forced to rotate in relation to each other. Frictional resistance between the two members is dampening the rotational movement and thus the displacement in the system. The invention further relates to a device wherein the frictional resistance may be varied dynamically based on the displacements occurring in the system.

Owner:DAMPTECH AS

Ophthalmologic irrigation solutions and method

Solutions for perioperative intraocular application by continuous irrigation during ophthalmologic procedures are provided. These solutions include multiple agents that act to inhibit inflammation, inhibit pain, effect mydriasis (dilation of the pupil), and / or decrease intraocular pressure, wherein the multiple agents are selected to target multiple molecular targets to achieve multiple differing physiologic functions, and are included in dilute concentrations in a balanced salt solution carrier.

Owner:RAYNER SURGICAL (IRELAND) LTD

Device for damping movements of structural elements and a bracing system

InactiveUS20050115170A1Dampen grinding noiseSimple designProtective buildings/sheltersFriction dampersApartment houseStructural system

The invention relates to the protection of structural systems such as apartment houses against dynamic loading caused by earthquakes, wind, traffic etc. When a frame structure is excited by a horizontal external force, the girders starts to displace horizontally. If such displacements are large or if they occur periodically they may have serious impact on the conditions of the structure and may cause severe damages or even result in a collapse. The present invention relates to a very simply designed and easily produced damper with two members being interconnected in a rotational joint. By means of the arrangement of the damper in the structural system, displacement occurring in the system is transferred to the members being forced to rotate in relation to each other. Frictional resistance between the two members is dampening the rotational movement and thus the displacement in the system. The invention further relates to a device wherein the frictional resistance may be varied dynamically based on the displacements occurring in the system.

Owner:MUALLA IMAD H

Stabilizing agent for peroxide-bleaching procedure and methods of bleaching a fiber material by using same

InactiveUS6120556AImprove bleaching effectImprove efficiencyOrganic/inorganic per-compounds compounding agentsBleaching apparatusFiberBleach

A stabilizing agent for peroxide-bleaching procedure includes (A) a component including a homopolymer or copolymer of alpha -hydroxyacrylic acid or water soluble salt or polylactone of the homo- or co-polymer, (B) a component including a homopolymer or copolymer of acrylic acid, methacrylic acid and / or maleic acid and water-soluble salt of the homo- or co-polymer, (C) a component including DTPA, TTHA or water-soluble salt thereof and optionally (D) a component including a water-soluble inorganic Mg salt and is used to pretreat a fiber material with a pretreating liquid containing the stabilizing agent before bleaching with peroxide, or to bleach the fiber material by a bleaching liquid containing a peroxide bleaching agent and the stabilizing agent.

Owner:NIPPON PEROXIDE

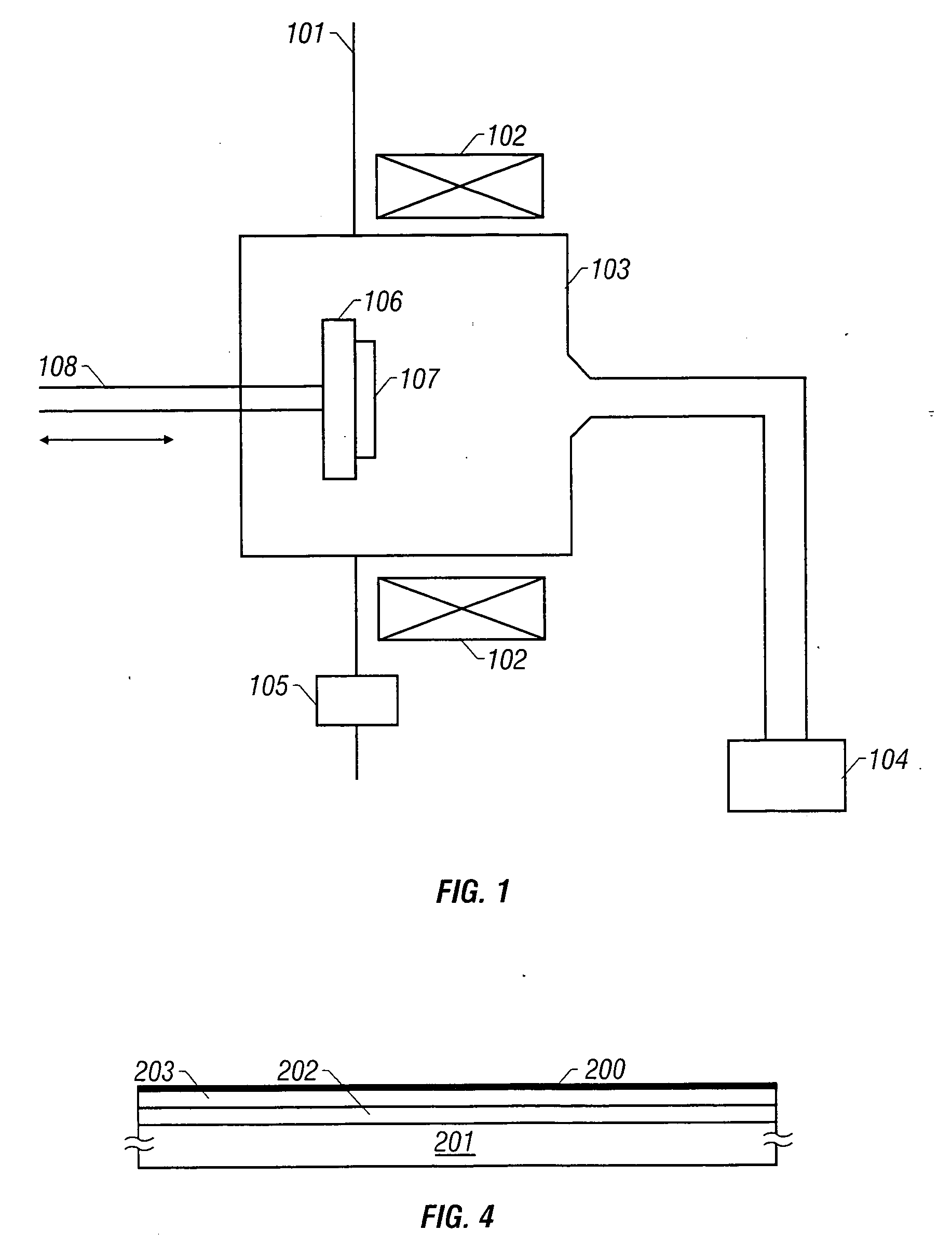

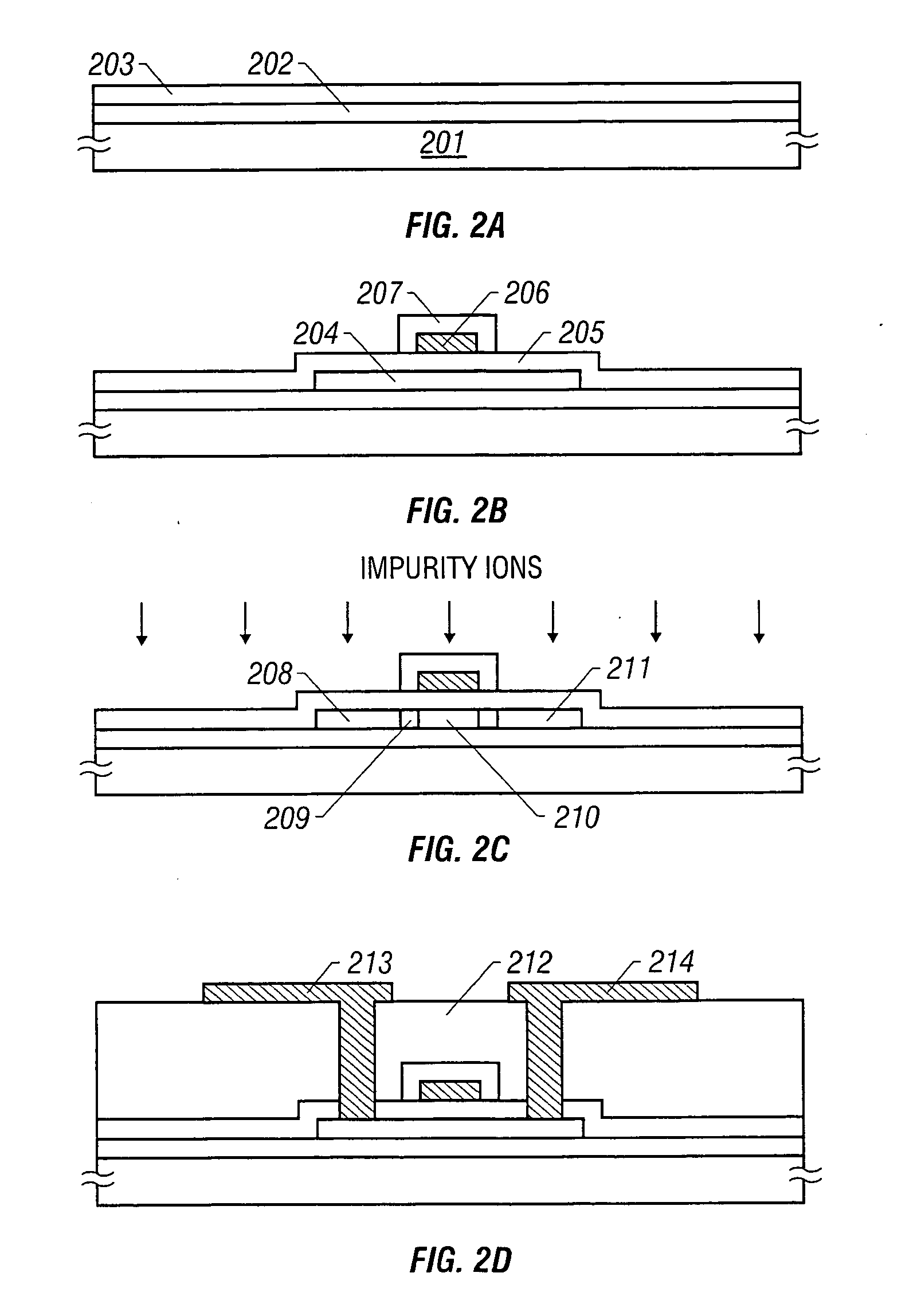

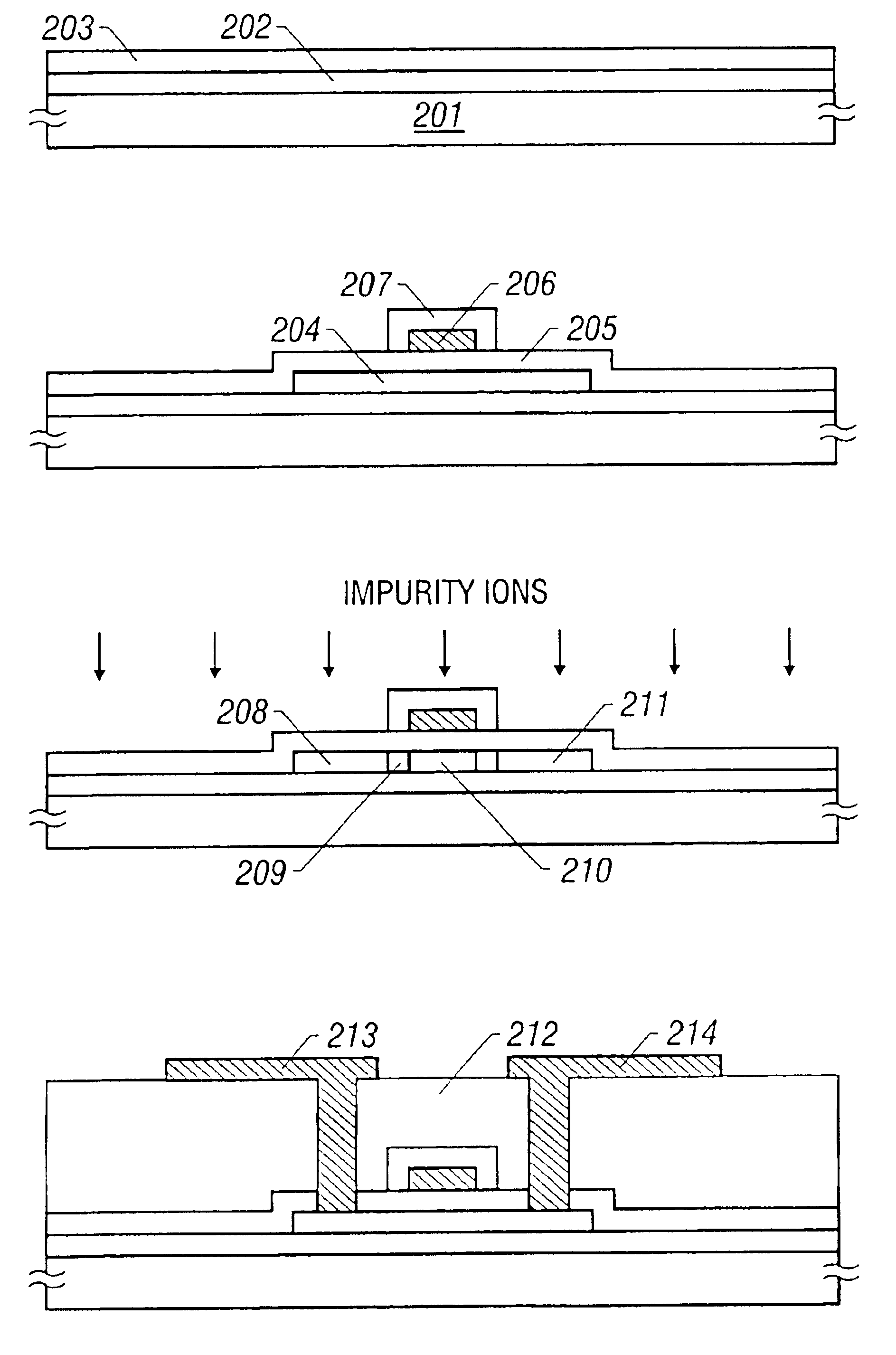

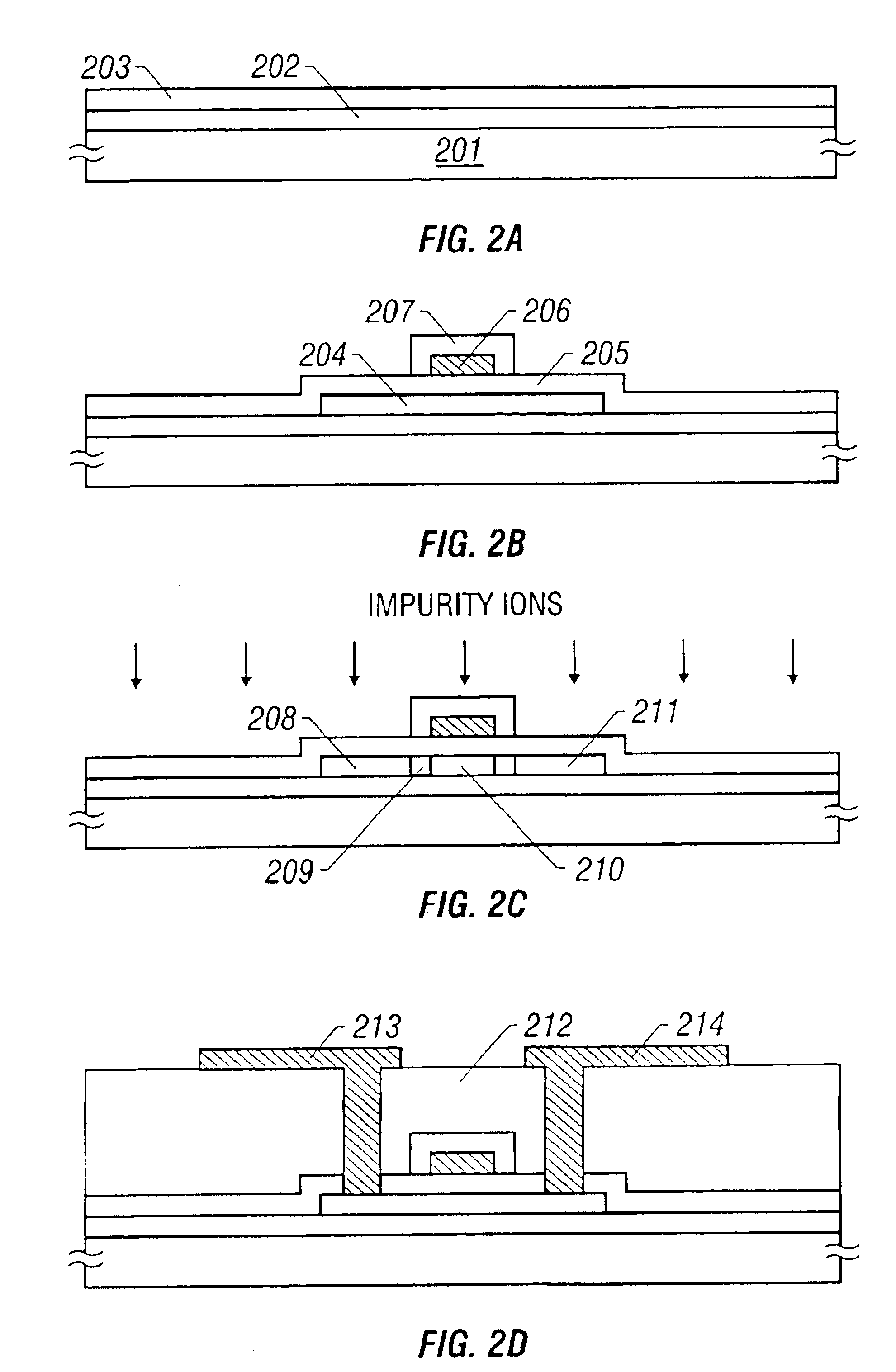

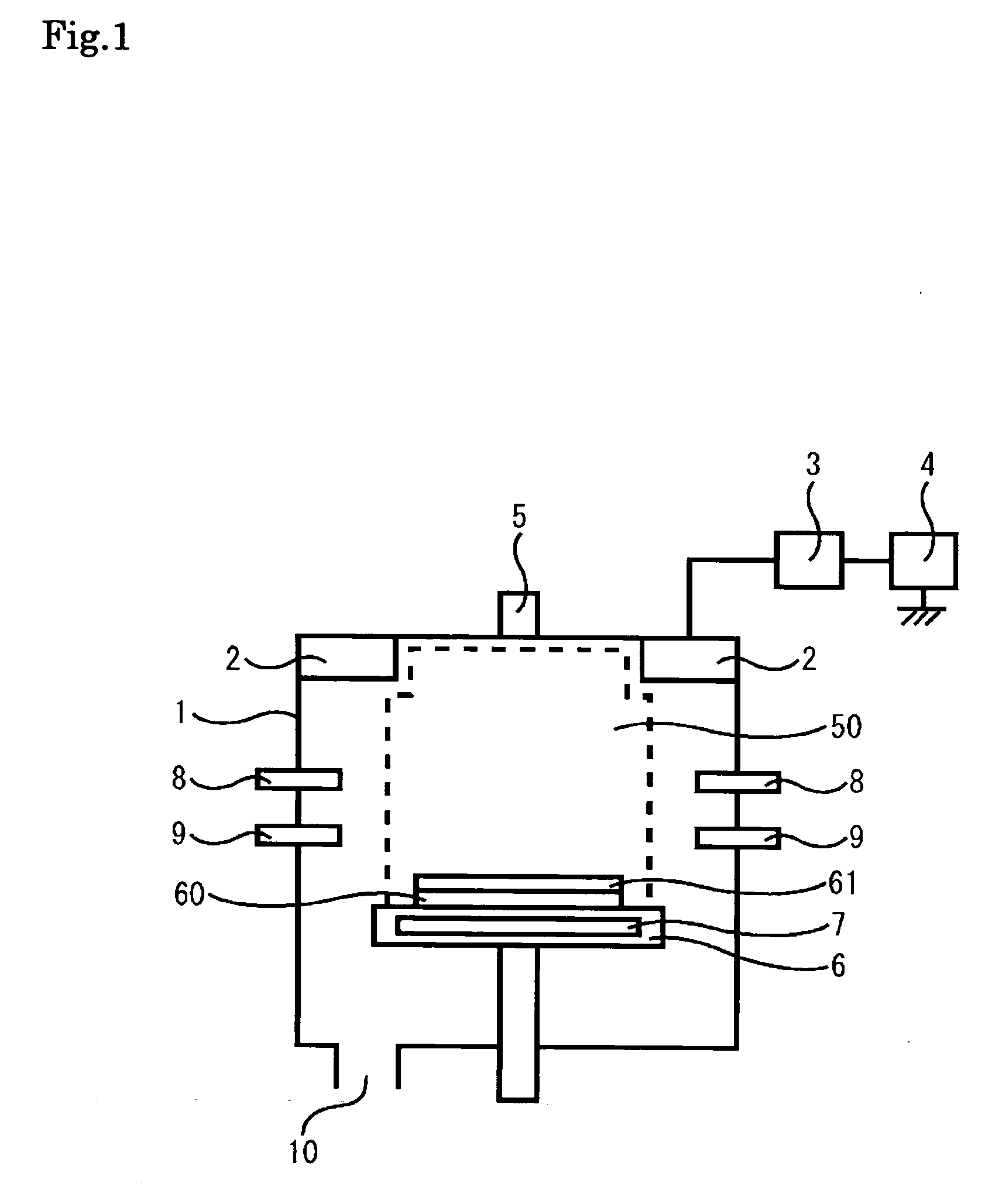

Method of manufacturing a semiconductor device and manufacturing system thereof

InactiveUS20050208714A1Efficient processConstant effectTransistorSolid-state devicesHydrogenDevice material

A method of manufacturing a semiconductor device, comprises the steps of: forming an amorphous silicon film on a substrate having an insulating surface; processing said amorphous silicon film by plasma of a gas that mainly contains hydrogen or helium; and giving an energy to said amorphous silicon film.

Owner:SEMICON ENERGY LAB CO LTD

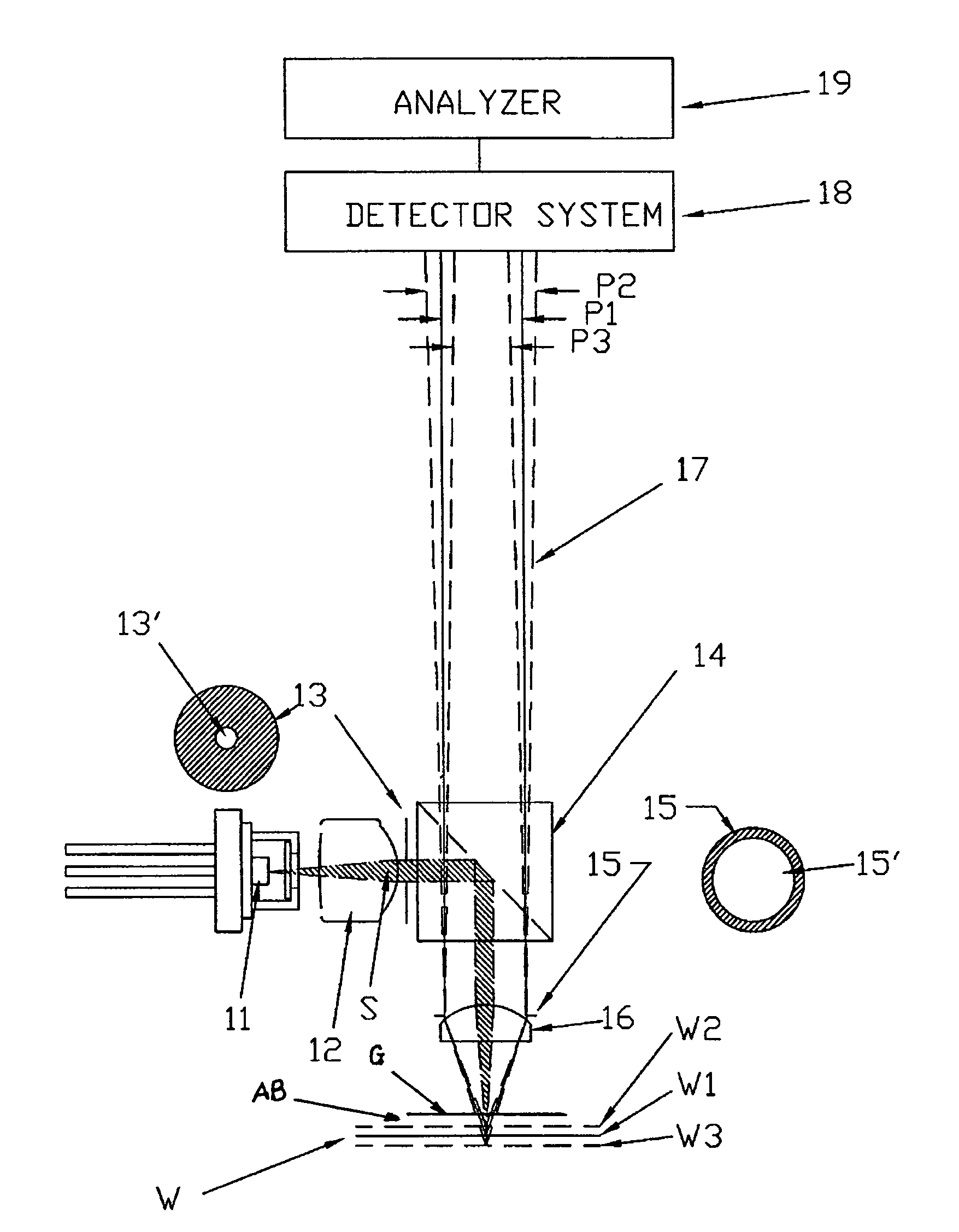

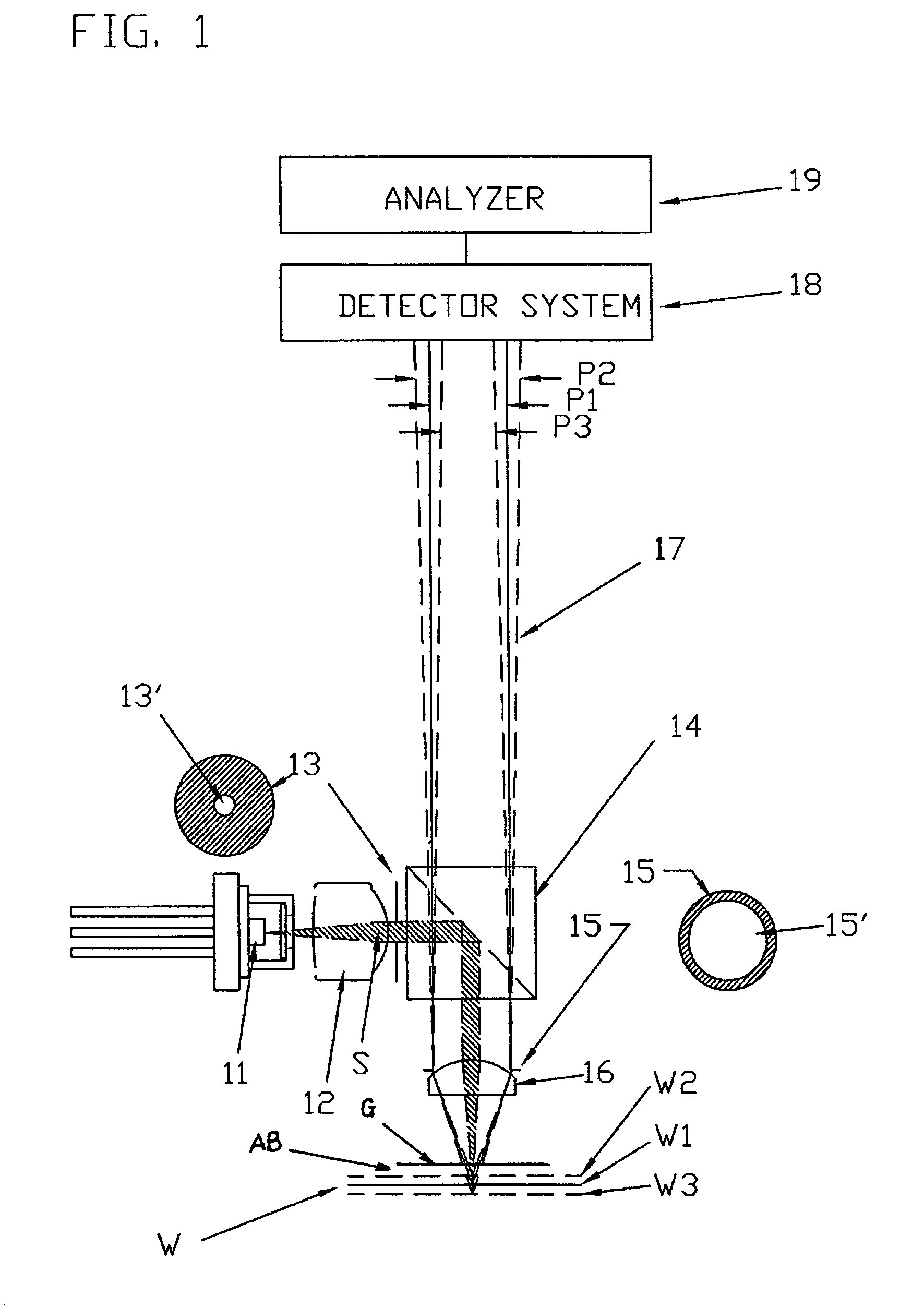

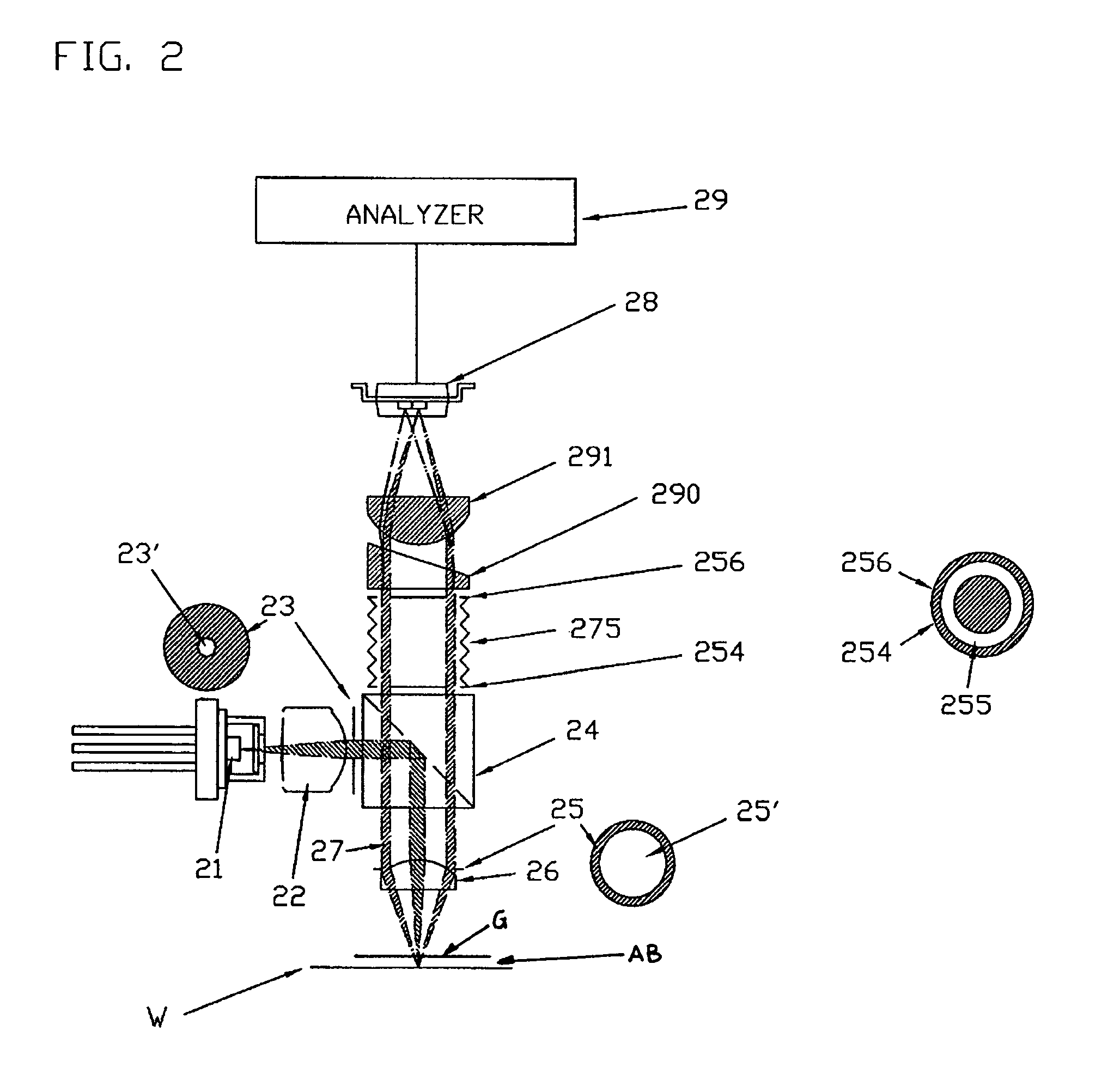

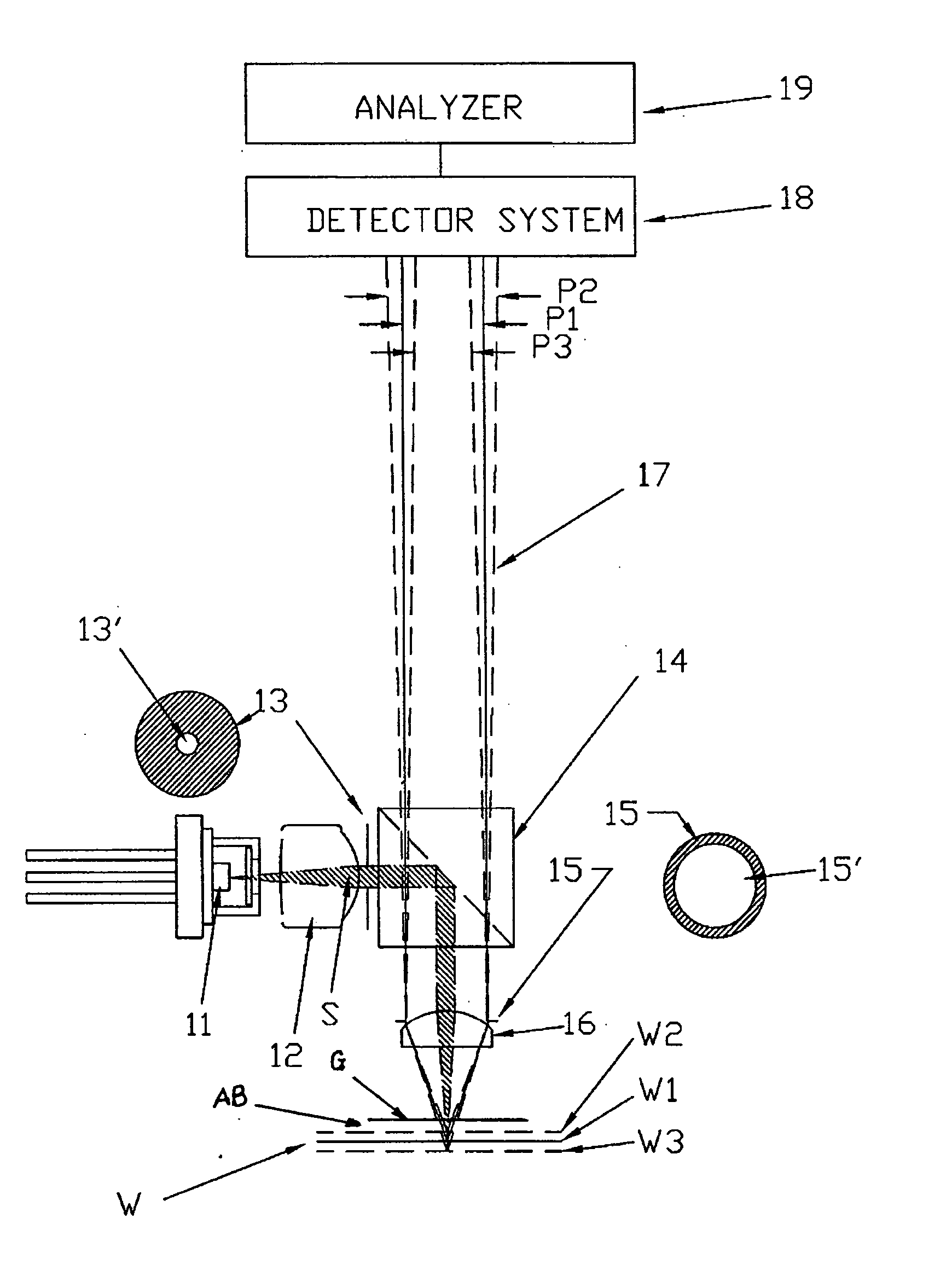

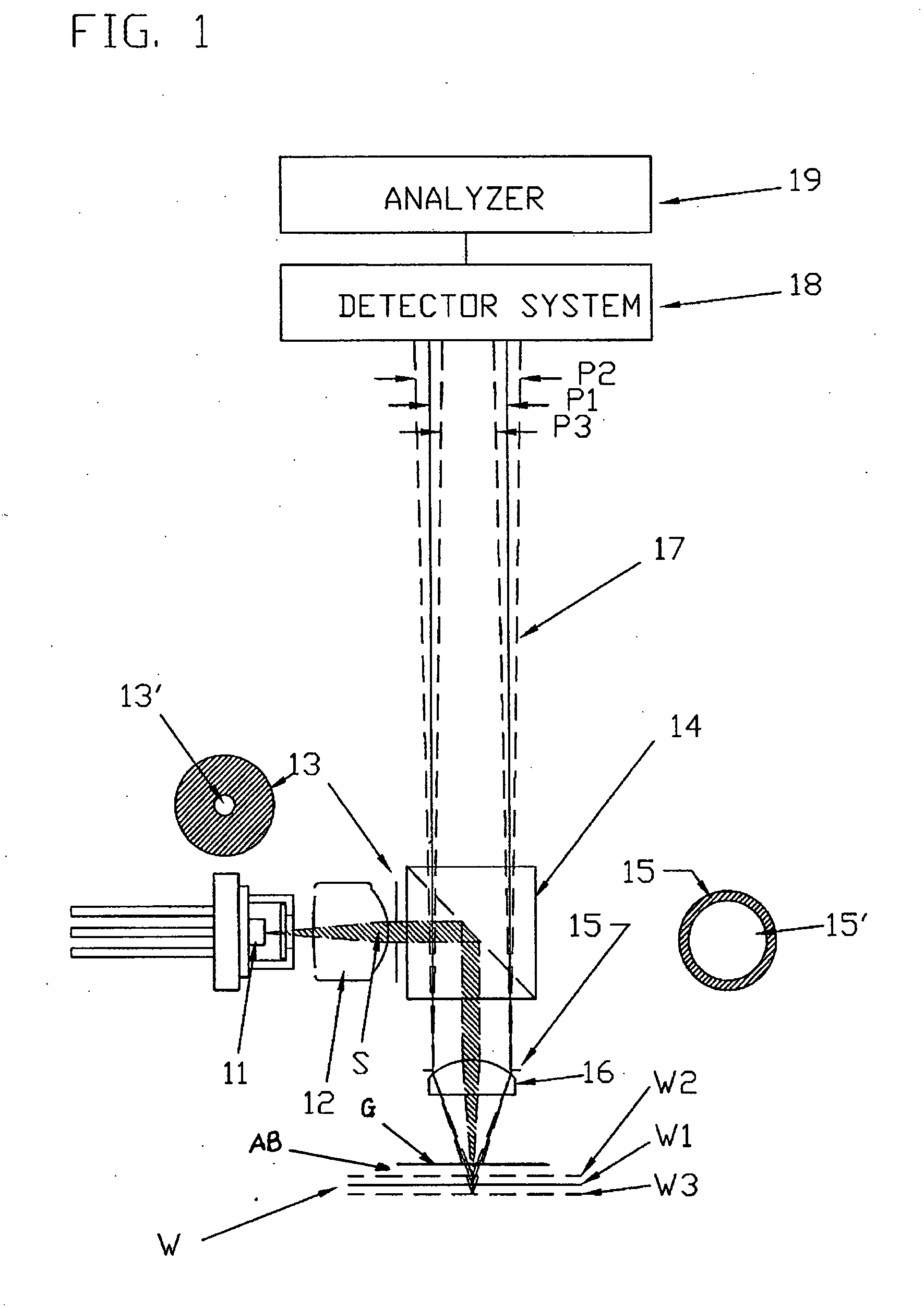

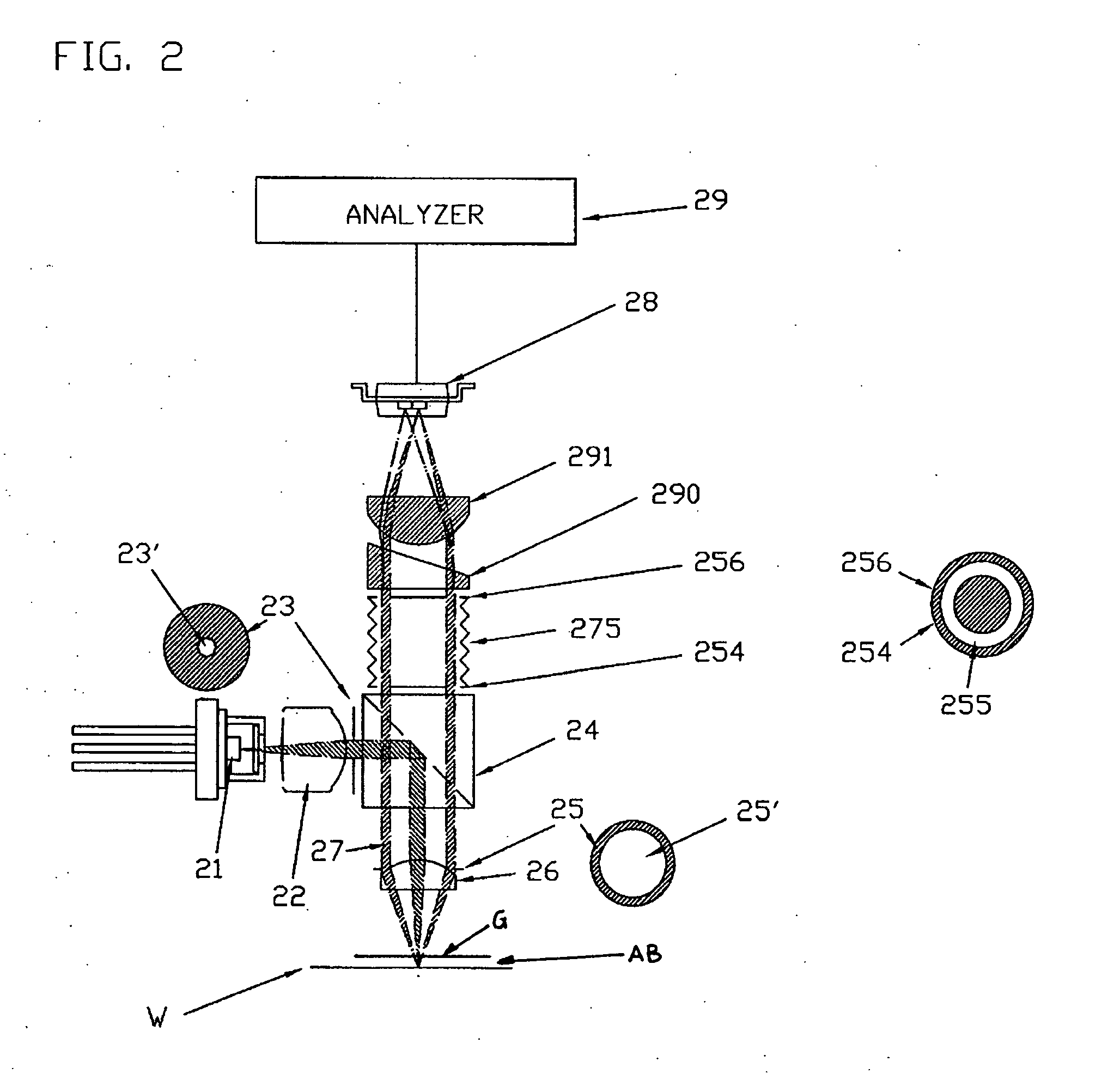

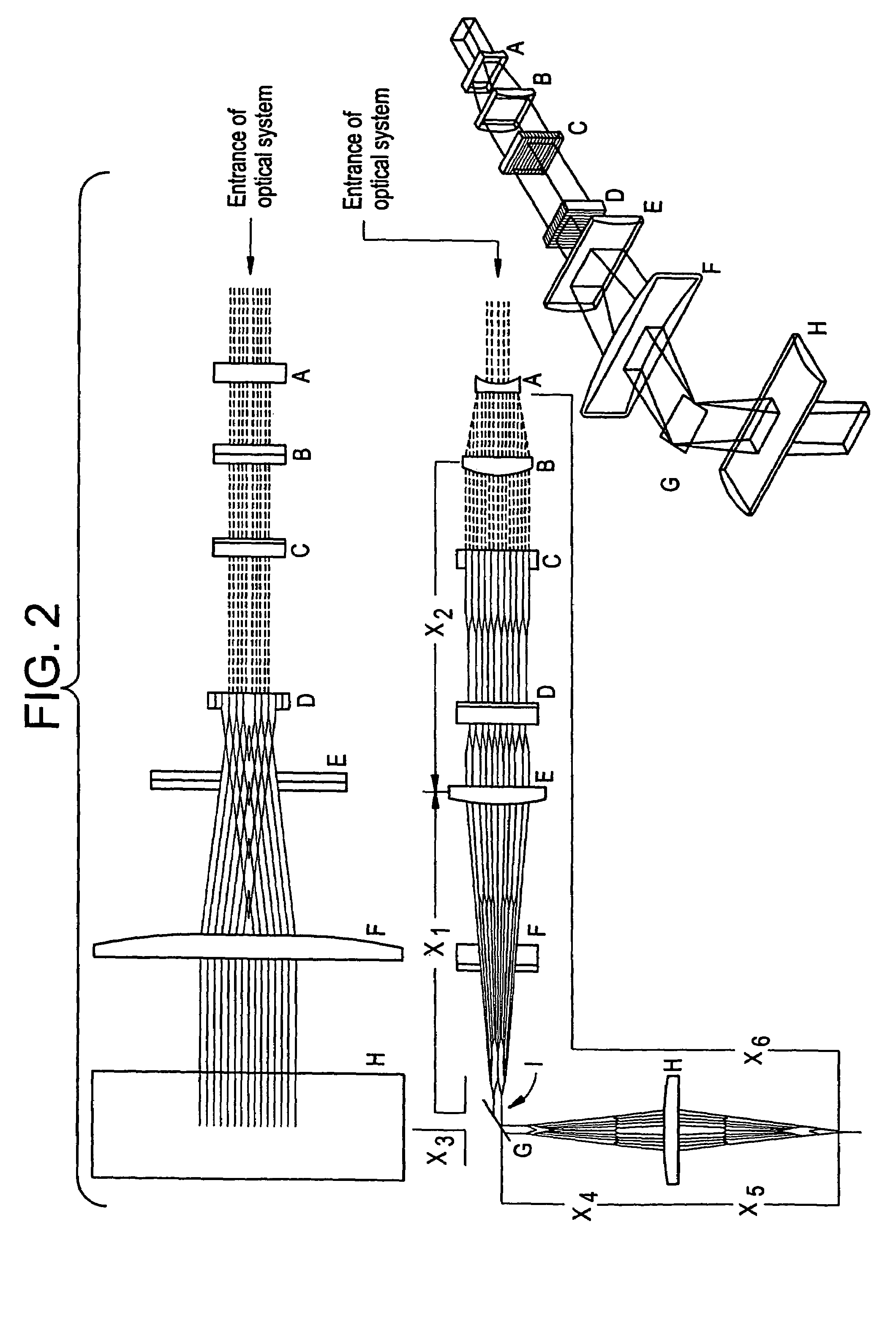

Device and process for optical distance measurement

InactiveUS7768629B2Constant effectAvoid disturbing influenceOptical rangefindersUsing optical meansObject basedLight beam

Device and process for determining a distance to an object. The device includes a low coherence light source, at least one lens arranged to focus light from the low coherence light source onto the object and to collect light reflected and scattered from the object, and a window arranged between the lens and the object. An apertured element includes a circular aperture structured and arranged to form a circular light beam from the reflected and scattered light, and a detector system is structured and arranged to receive the circular light beam. The detector system is sensitive to light beam diameter. Further, a determining device is structured and arranged to determine a distance to the object based upon signals from the detector system.

Owner:VOITH PATENT GMBH

Device and process for optical distance measurement

InactiveUS20070263203A1Constant effectAvoid disturbing influenceOptical rangefindersUsing optical meansObject basedLight beam

Device and process for determining a distance to an object. The device includes a low coherence light source, at least one lens arranged to focus light from the low coherence light source onto the object and to collect light reflected and scattered from the object, and a window arranged between the lens and the object. An apertured element includes a circular aperture structured and arranged to form a circular light beam from the reflected and scattered light, and a detector system is structured and arranged to receive the circular light beam. The detector system is sensitive to light beam diameter. Further, a determining device is structured and arranged to determine a distance to the object based upon signals from the detector system.

Owner:VOITH PATENT GMBH

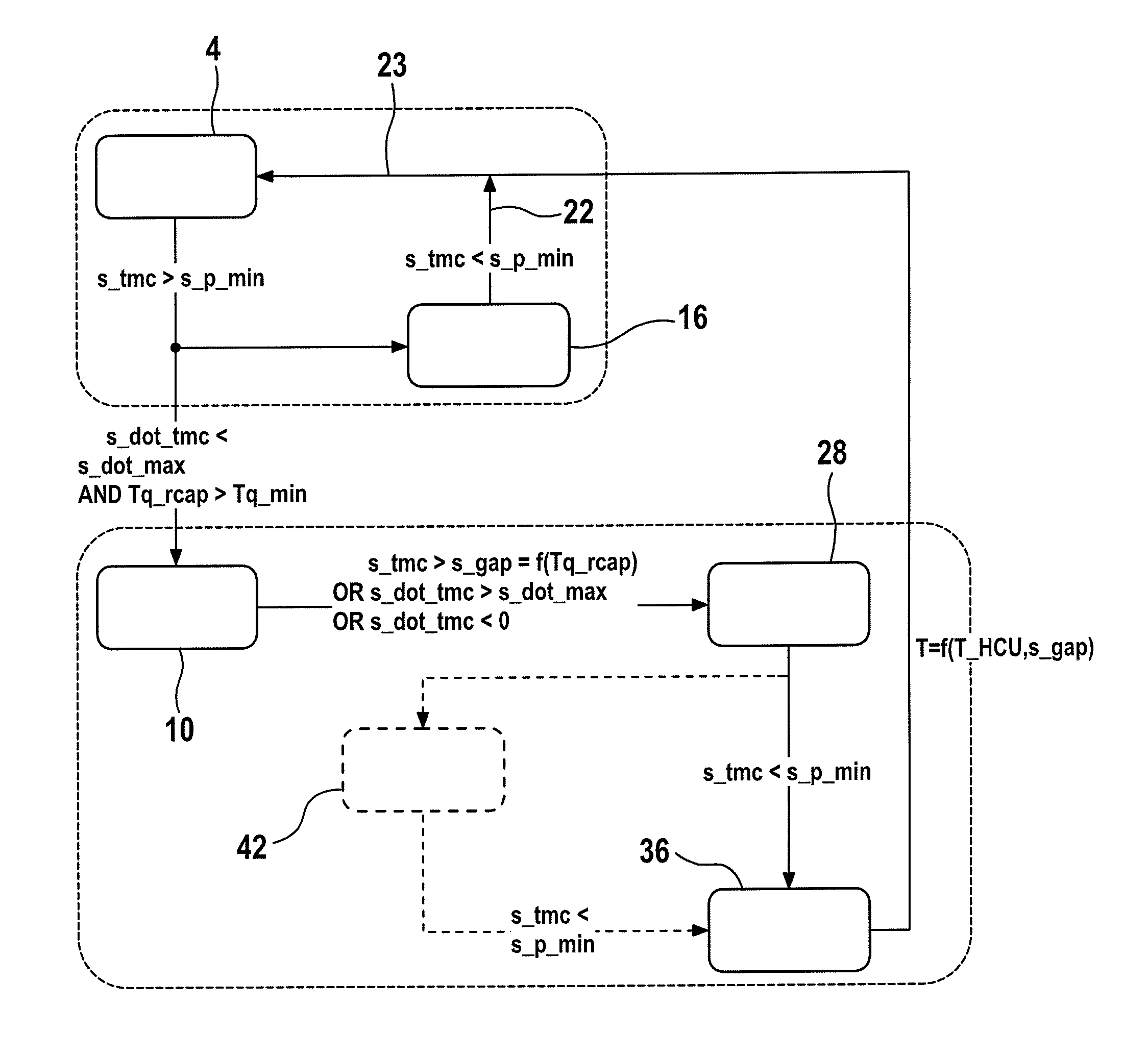

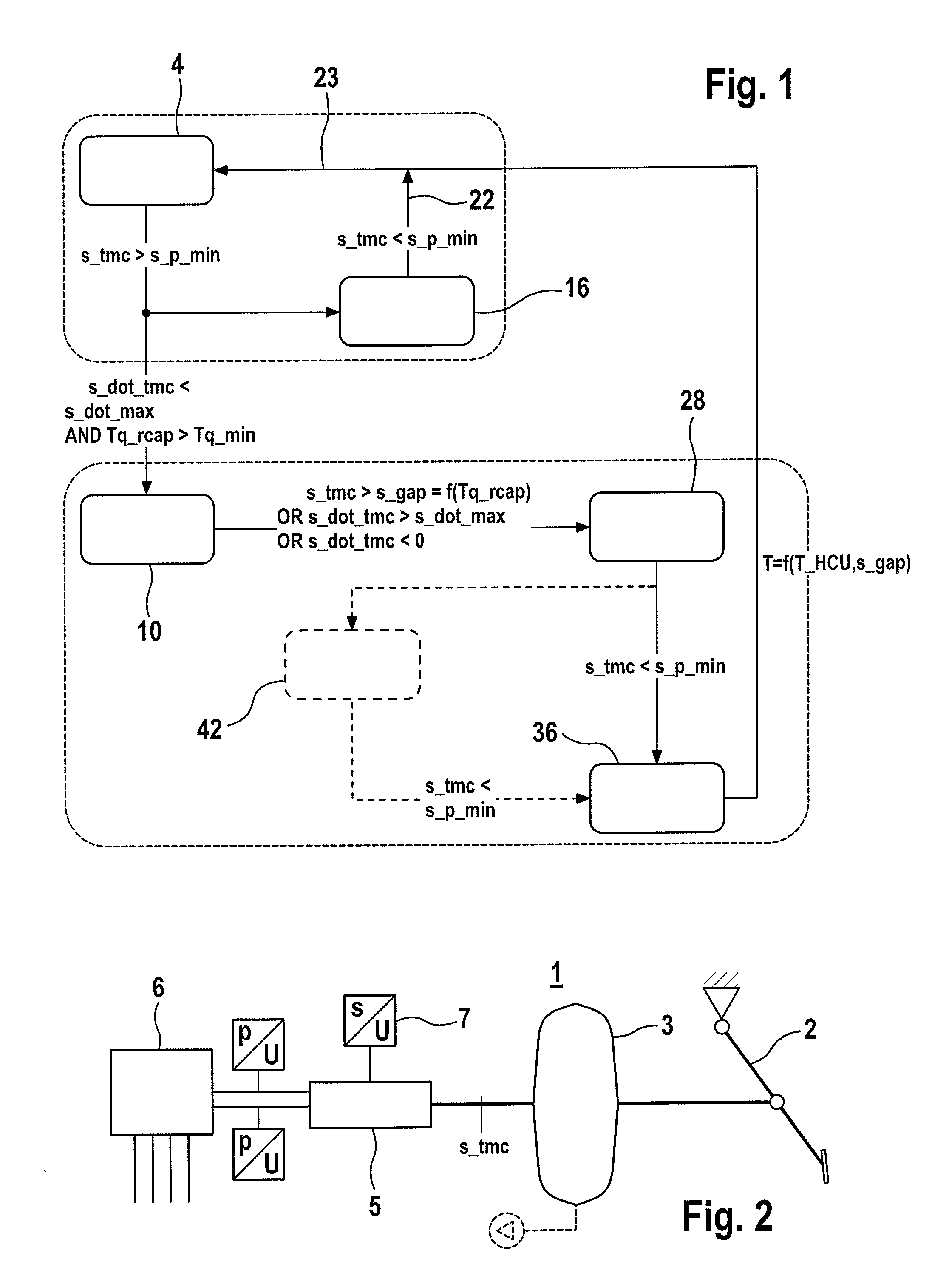

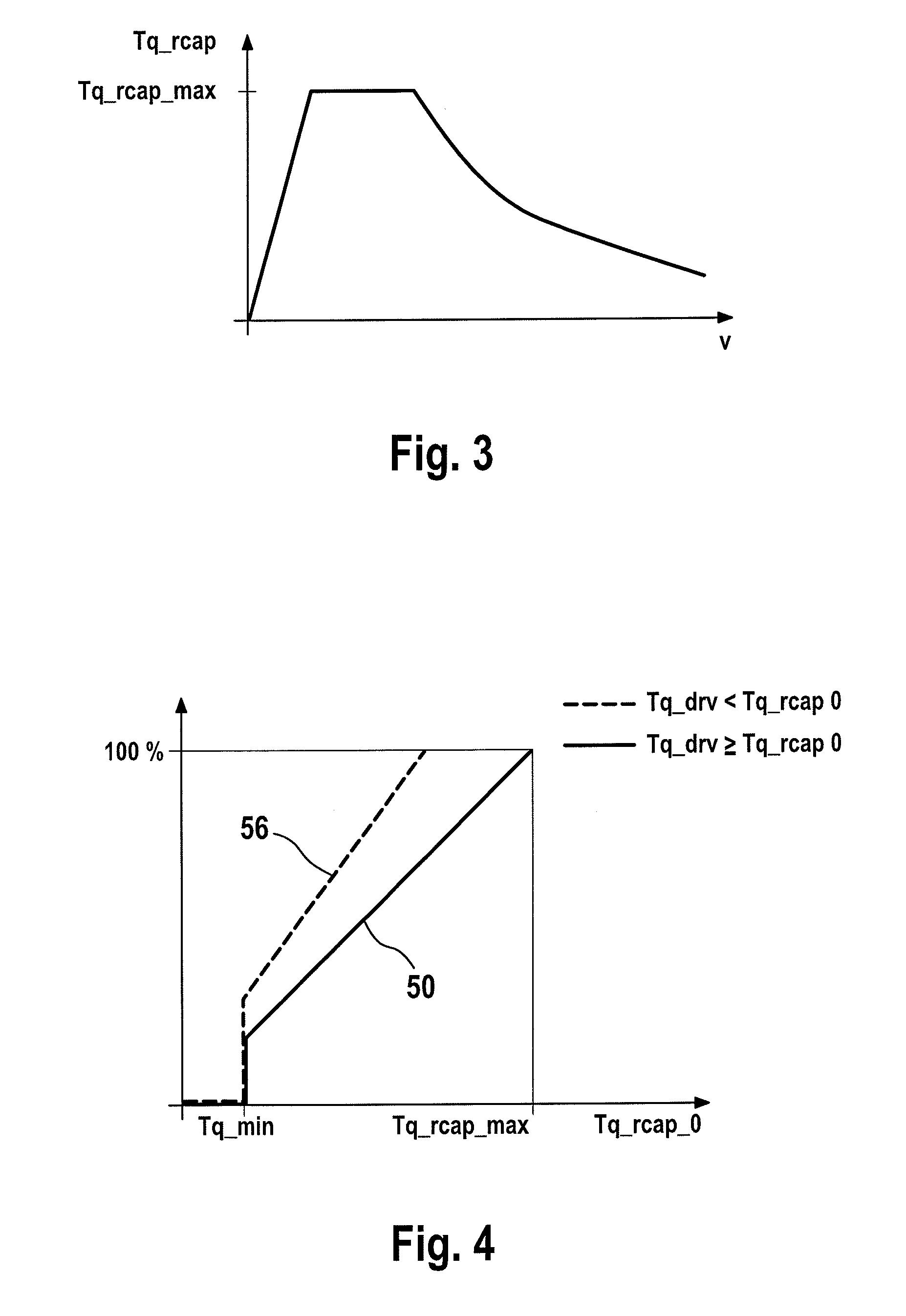

Method for operating a brake system, brake systems in which the method is carried out and motor vehicles comprising said brake systems

ActiveUS20130211685A1Constant effectImprove comfortBraking element arrangementsAnalogue computers for trafficBrake torqueRegenerative brake

A method for the operation of a brake system having two brake circuits, with a recuperative brake, in particular an electrical generator, a master brake cylinder and a brake pedal simultaneously achieve optimized use of the regenerative braking and a constant braking experience for the driver with the highest safety requirements. When there is a braking demand by the driver with an associated desired braking torque and a first condition is met, at least one outlet valve is opened and brake fluid is conducted with an associated volume of brake fluid into at least one reservoir and the at least one outlet valve is then closed if a second condition is met. The first condition is met if a braking variable corresponding to the braking demand is not less than a specified minimum value. The second condition is met if the volume of brake fluid has flowed into the reservoirs.

Owner:CONTINENTAL TEVES AG & CO OHG

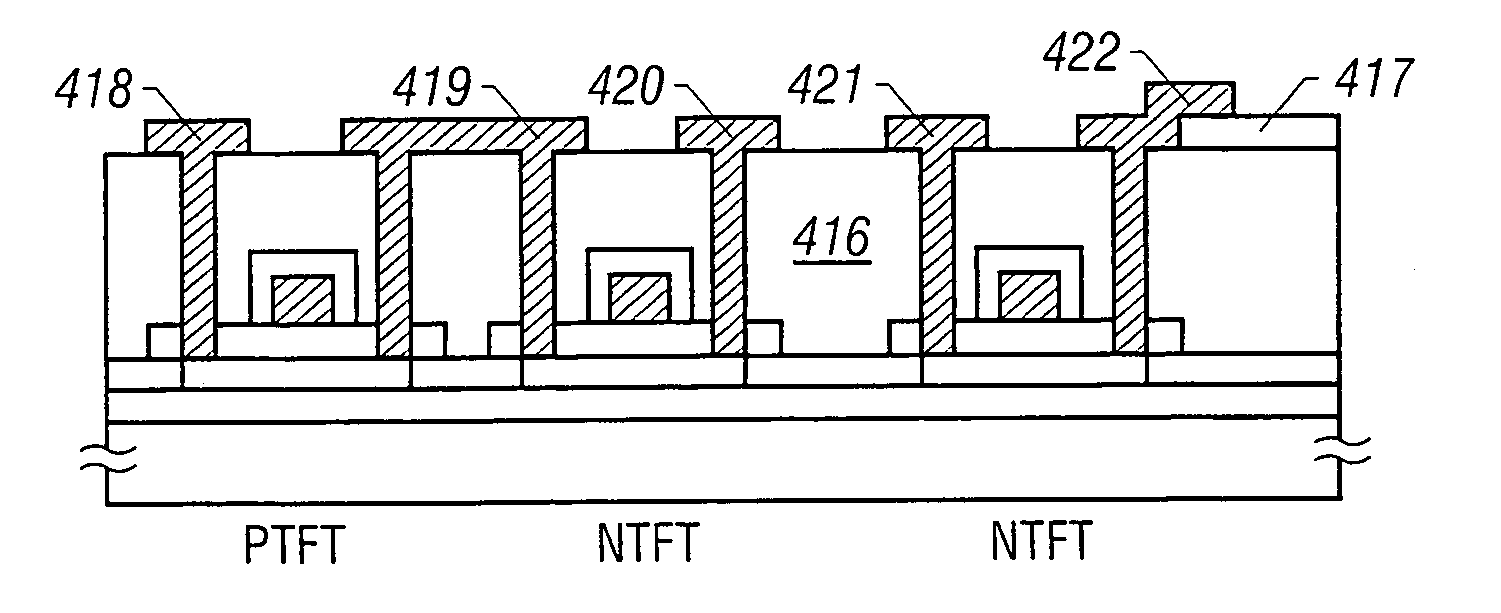

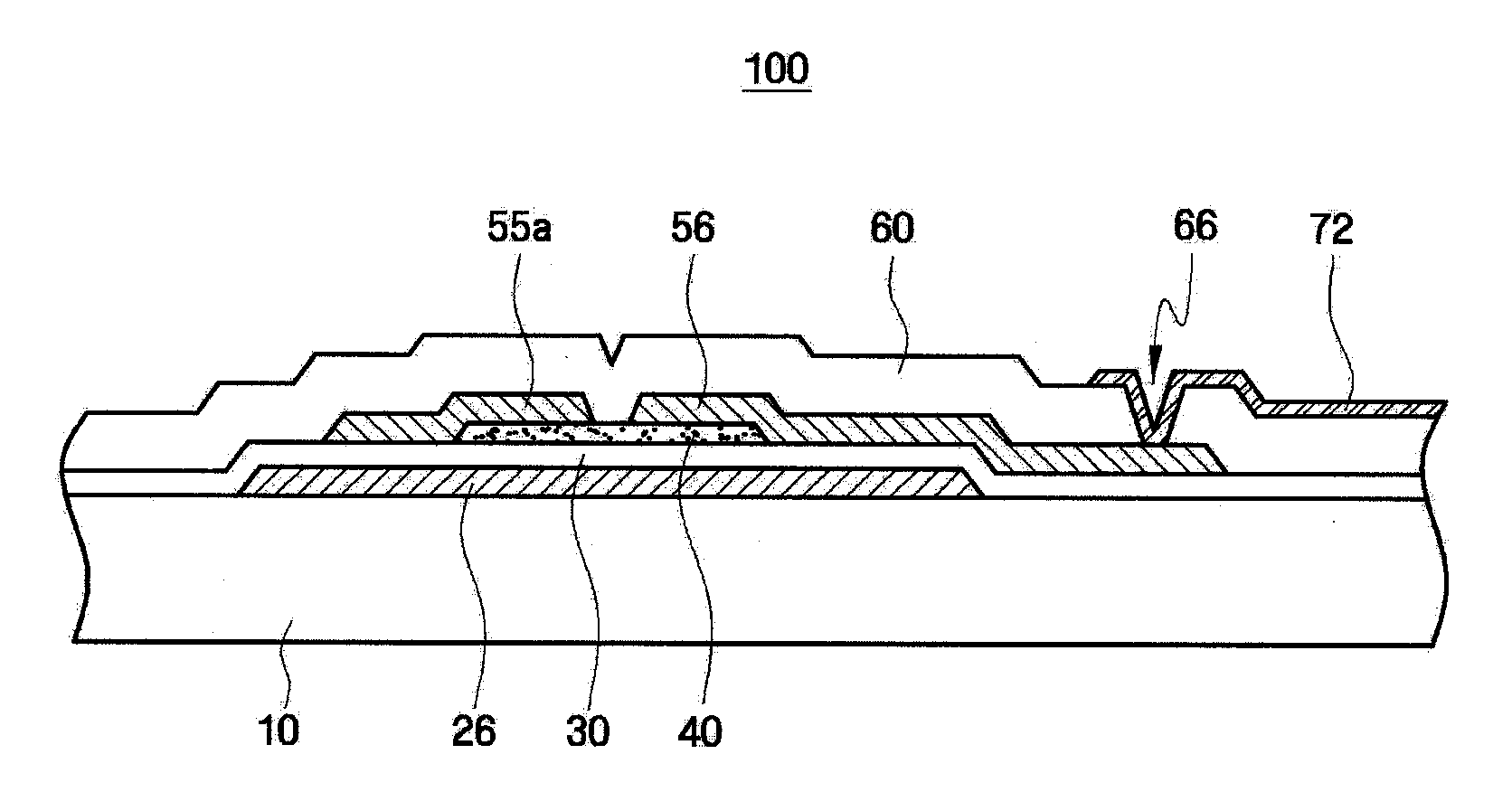

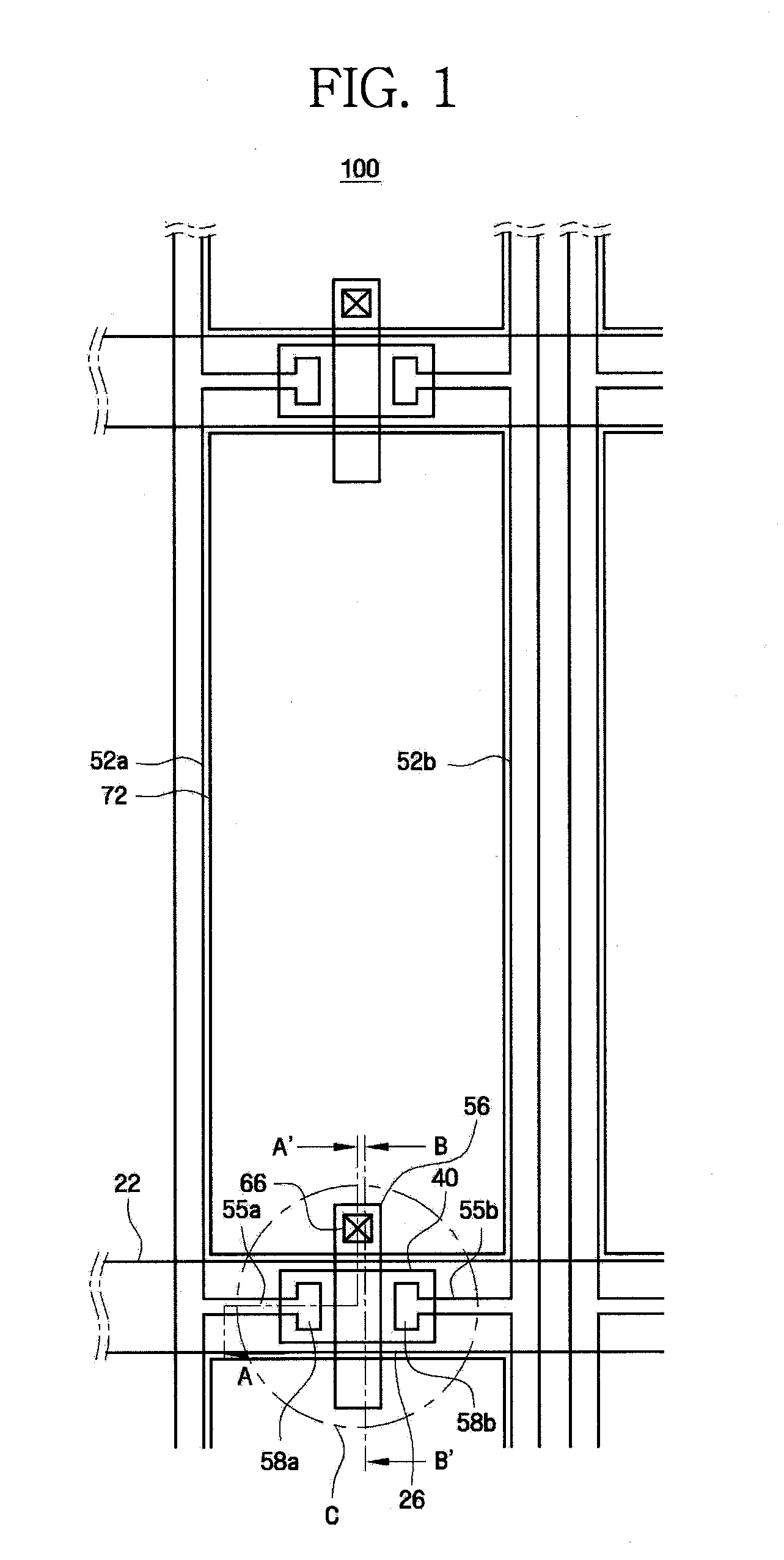

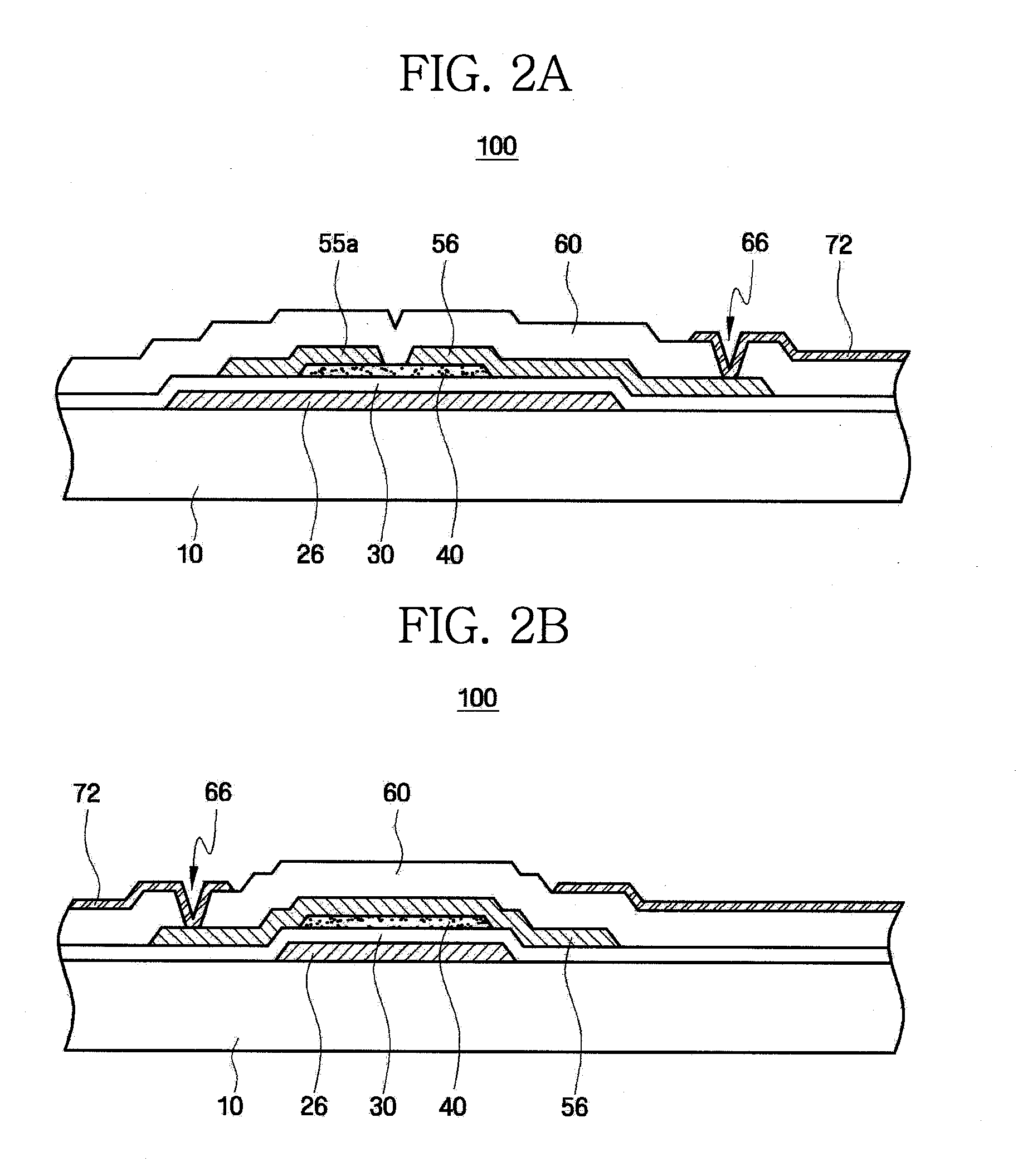

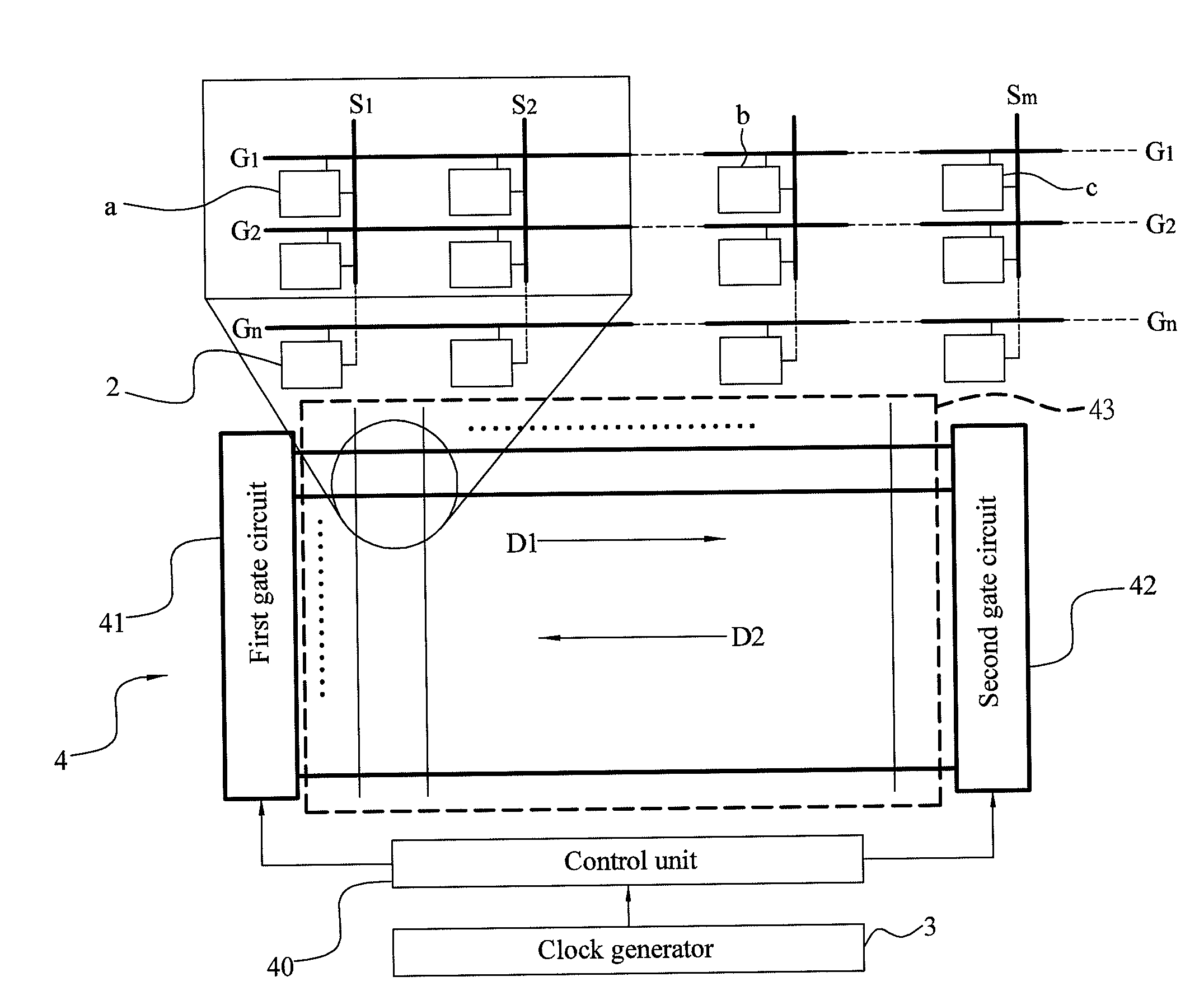

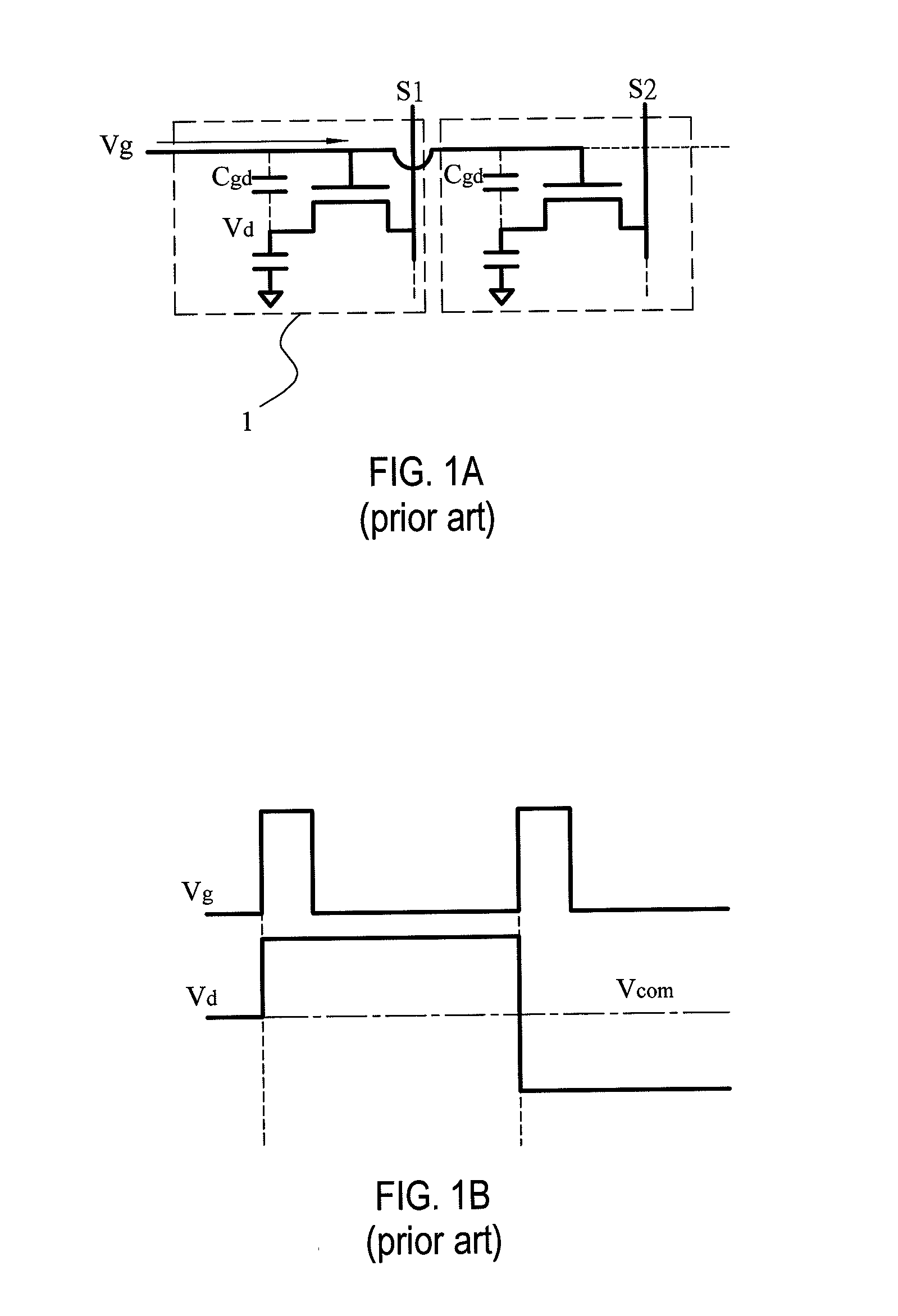

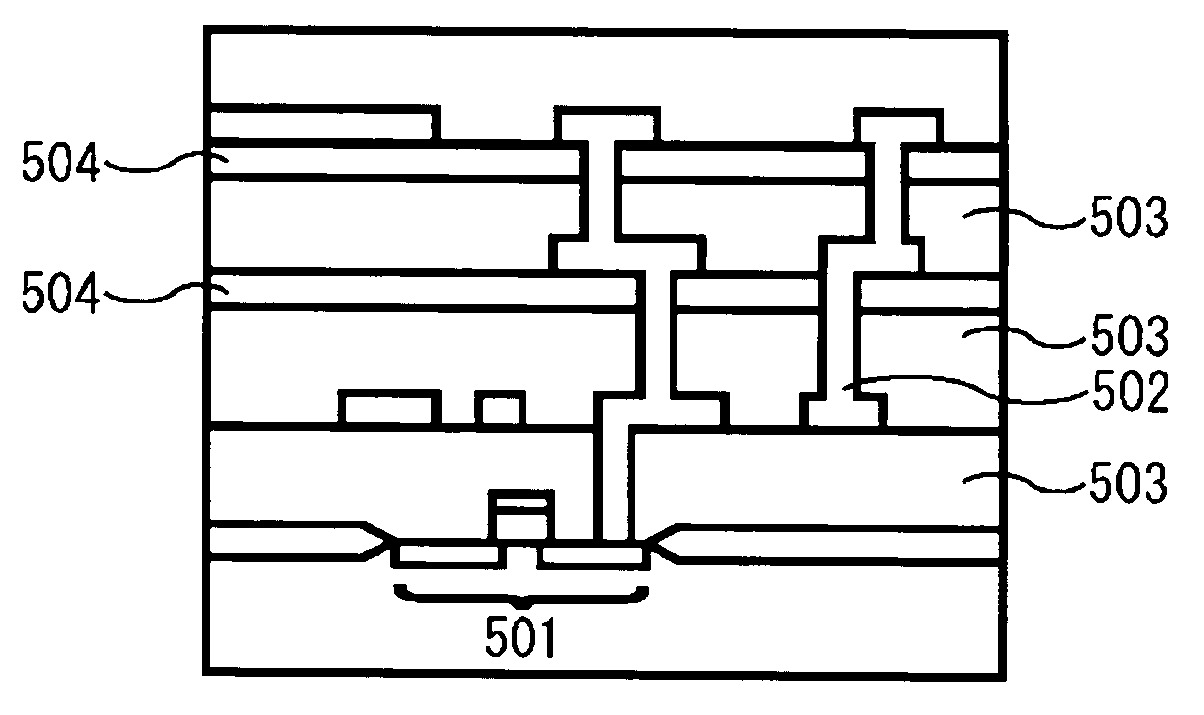

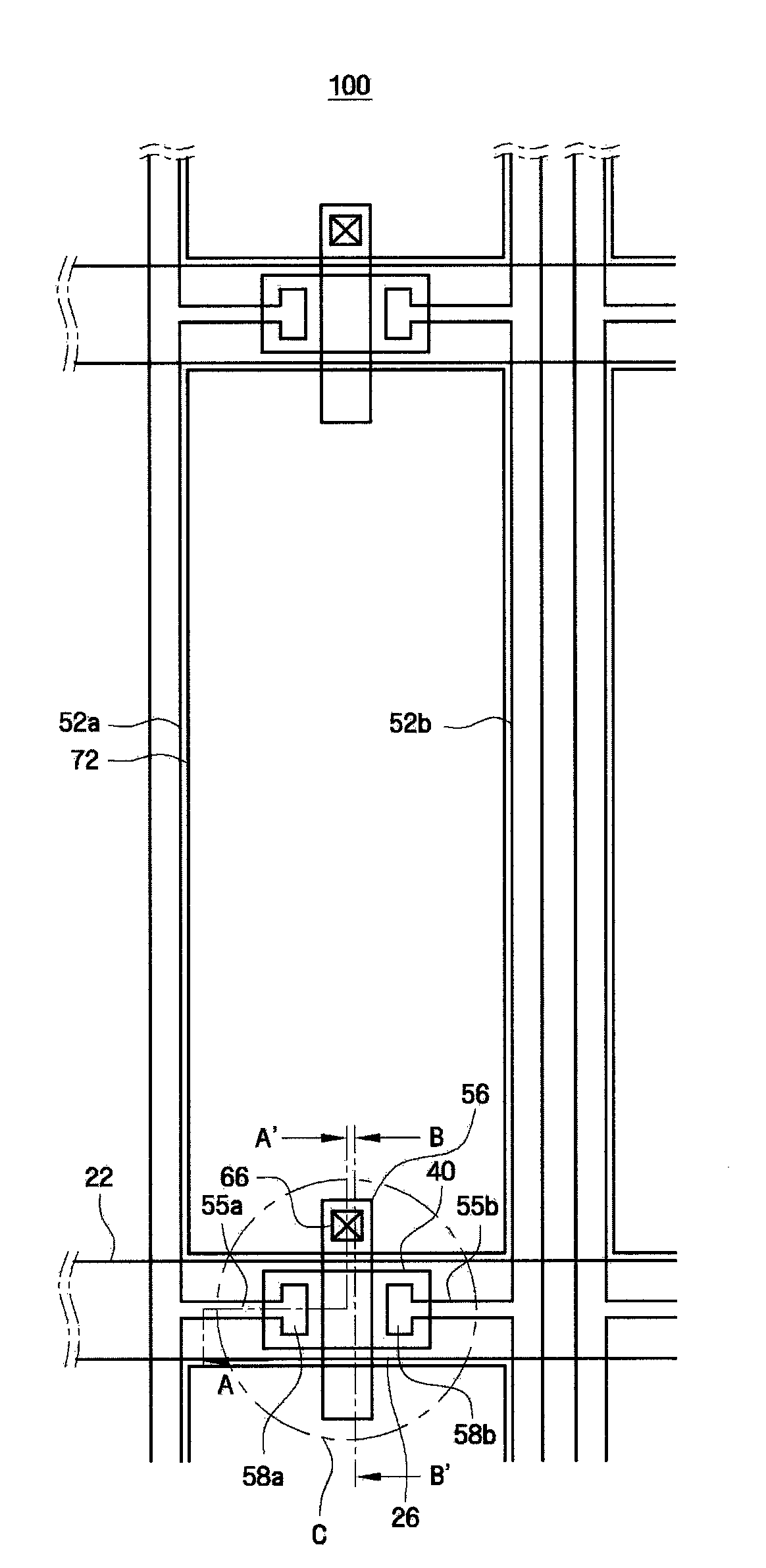

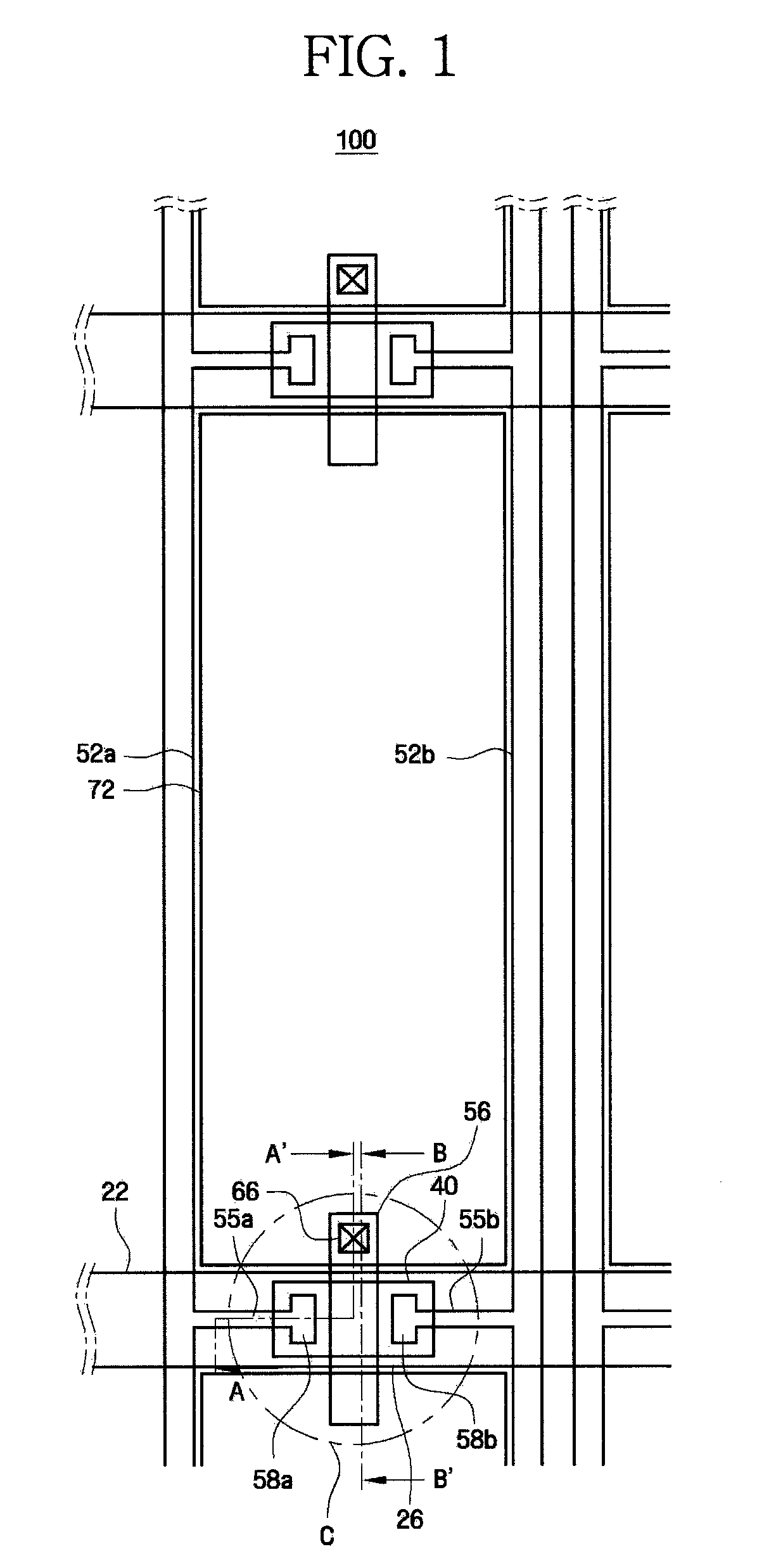

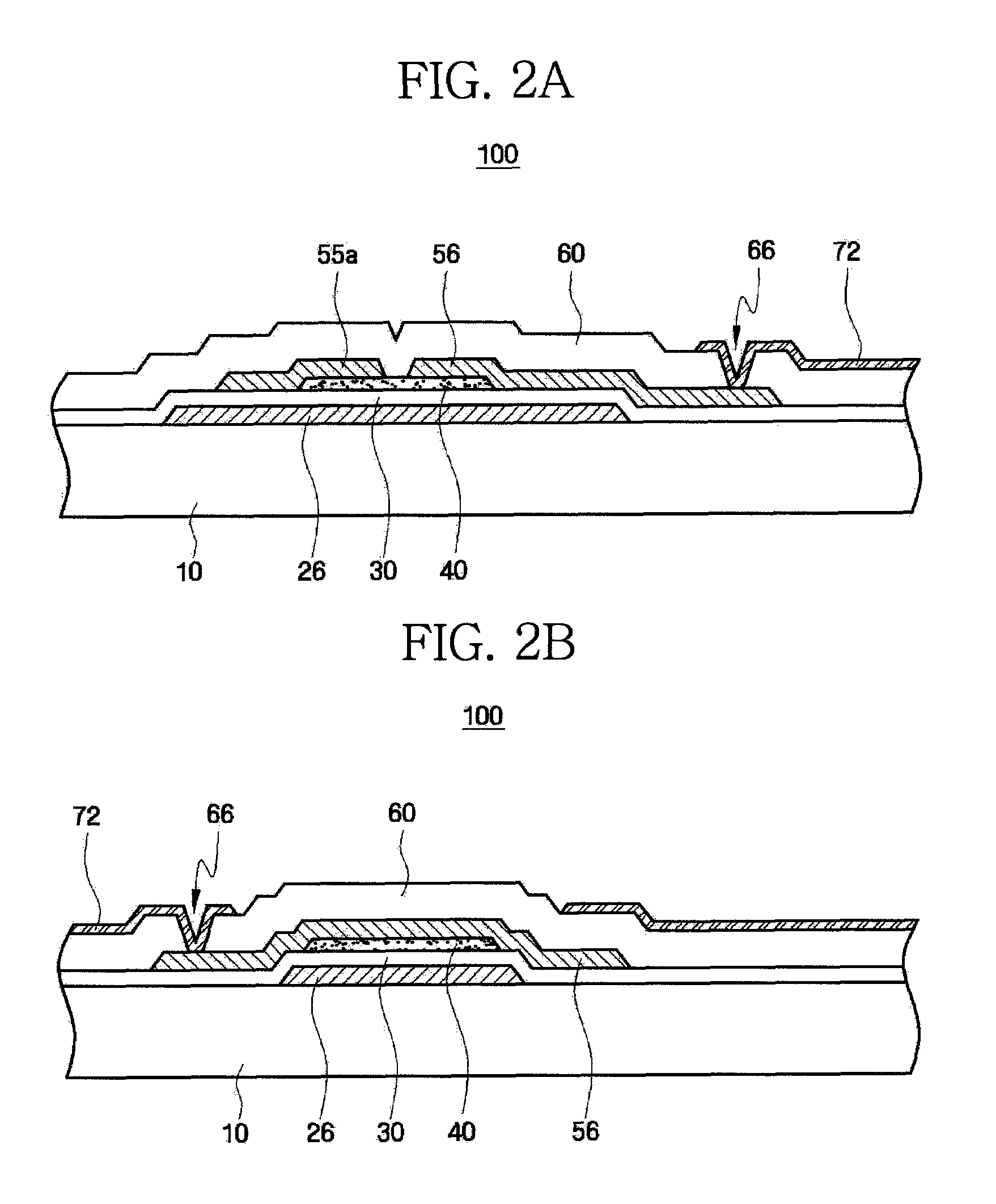

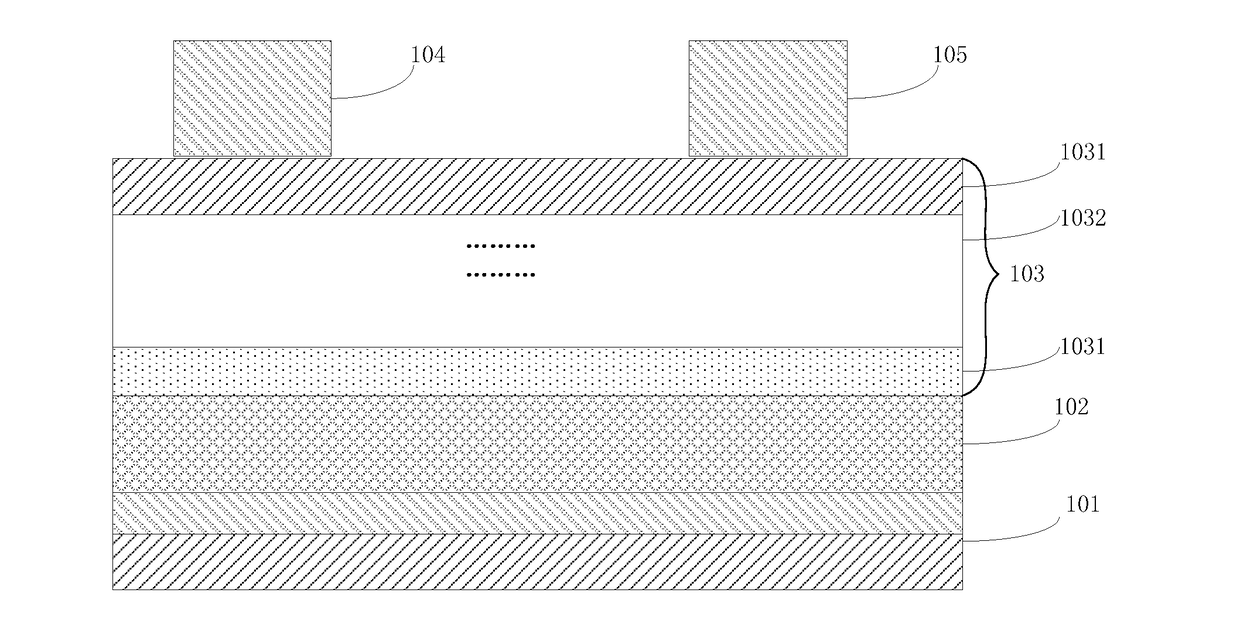

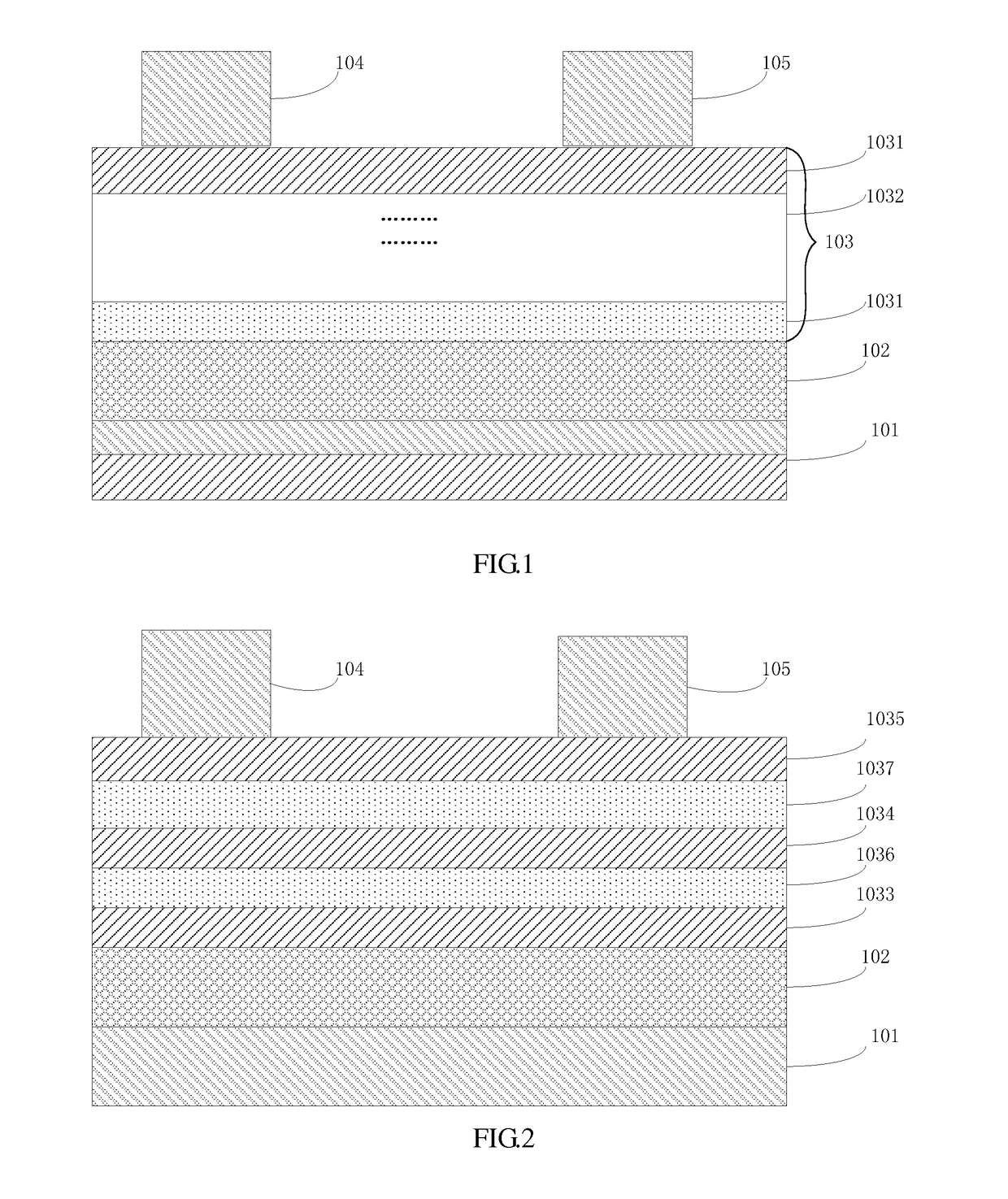

Thin film transistor substrate having structure for compensating for mask misalignment

ActiveUS20080078992A1Constant effectSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceActive layer

A thin film transistors (TFTs) substrate is structured to maintain as constant across the area of the substrate a kickback voltage due to Miller capacitance between the drain and gate of each TFT even in the presence of manufacturing induced misalignments between the drain electrodes and corresponding gate lines. Each thin film transistor includes a gate electrode, an active layer formed on the gate electrode so as to overlap the gate electrode, first and second source electrodes respectively connected to first and second data lines each of which crosses the gate line while being insulated from the gate line, and an elongated drain electrode located between the first and second source electrodes and disposed over the gate electrode so as to a crossing length of the drain electrode is larger than an underlying width of the gate electrode such that misalignment induced shifts of the position of the gate electrode relative to the drain electrode does not substantially change overlap area between the two.

Owner:SAMSUNG DISPLAY CO LTD

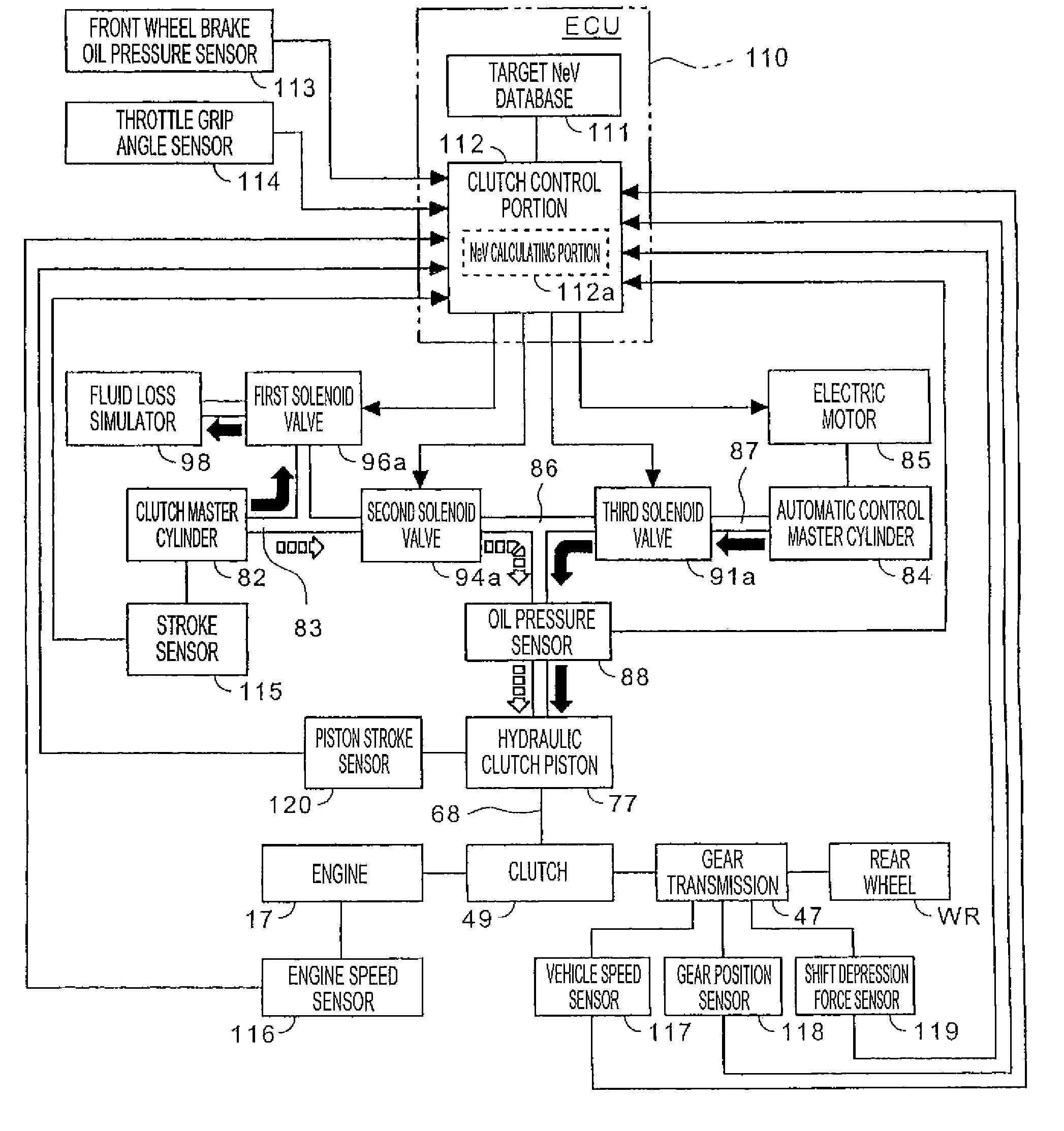

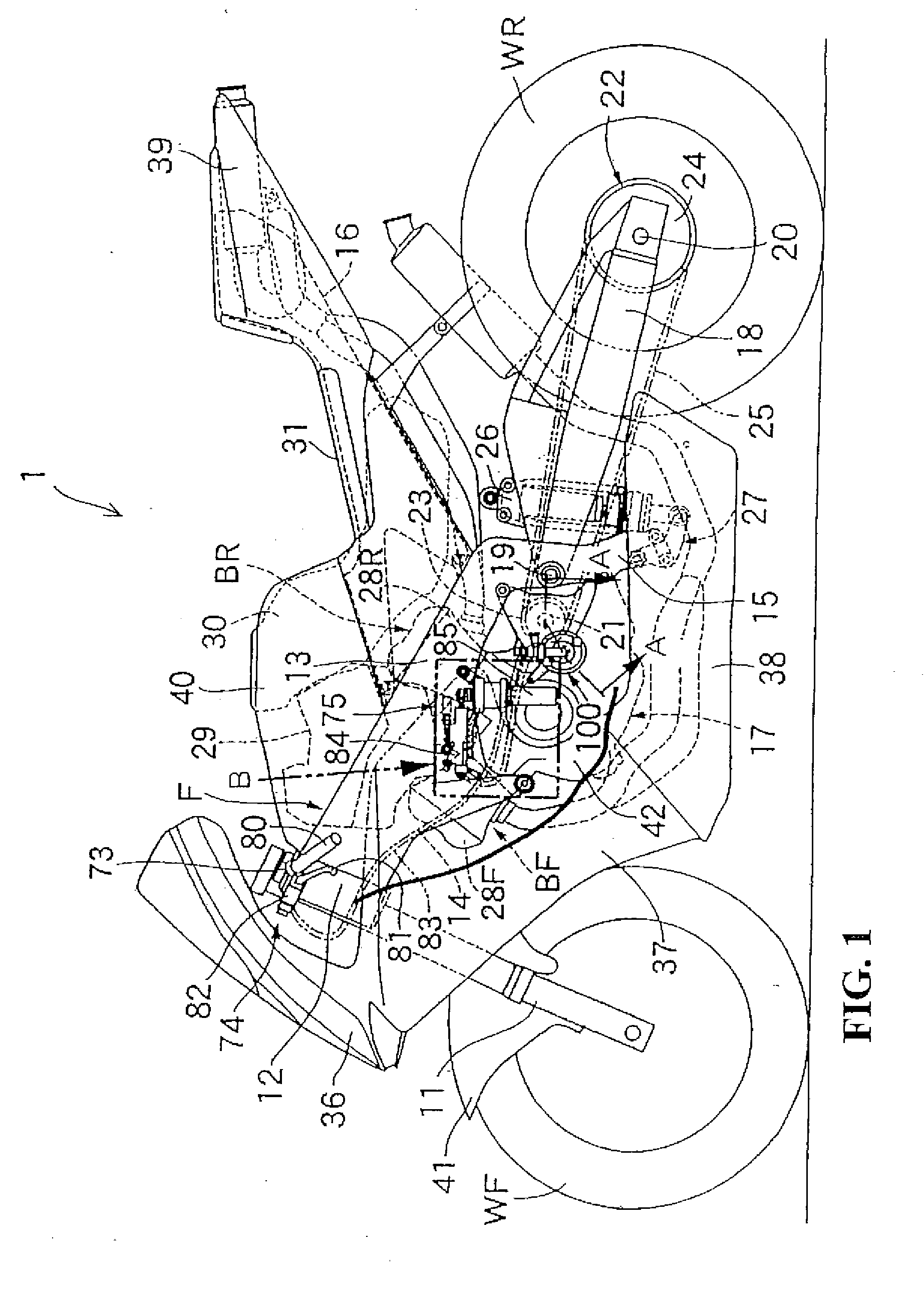

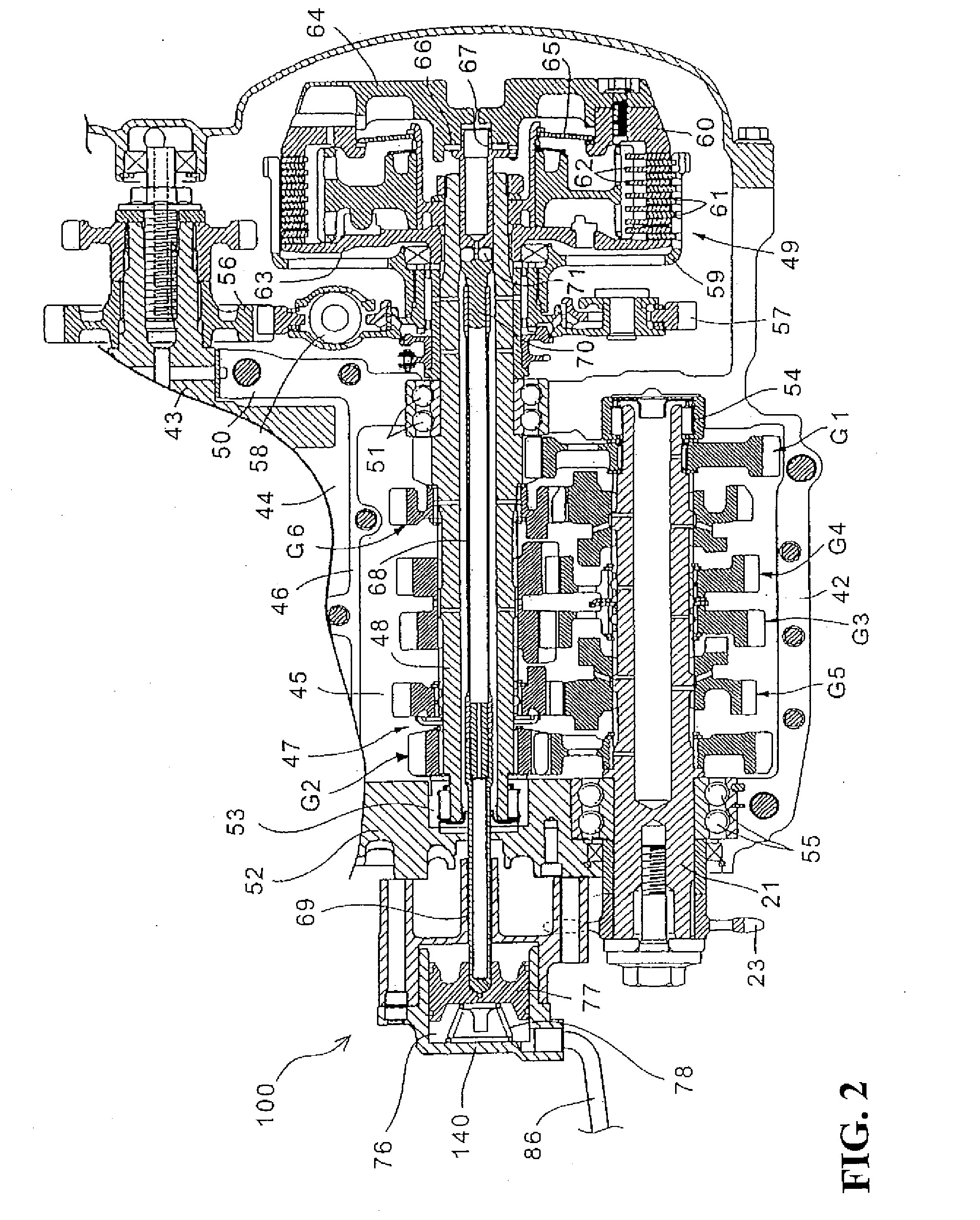

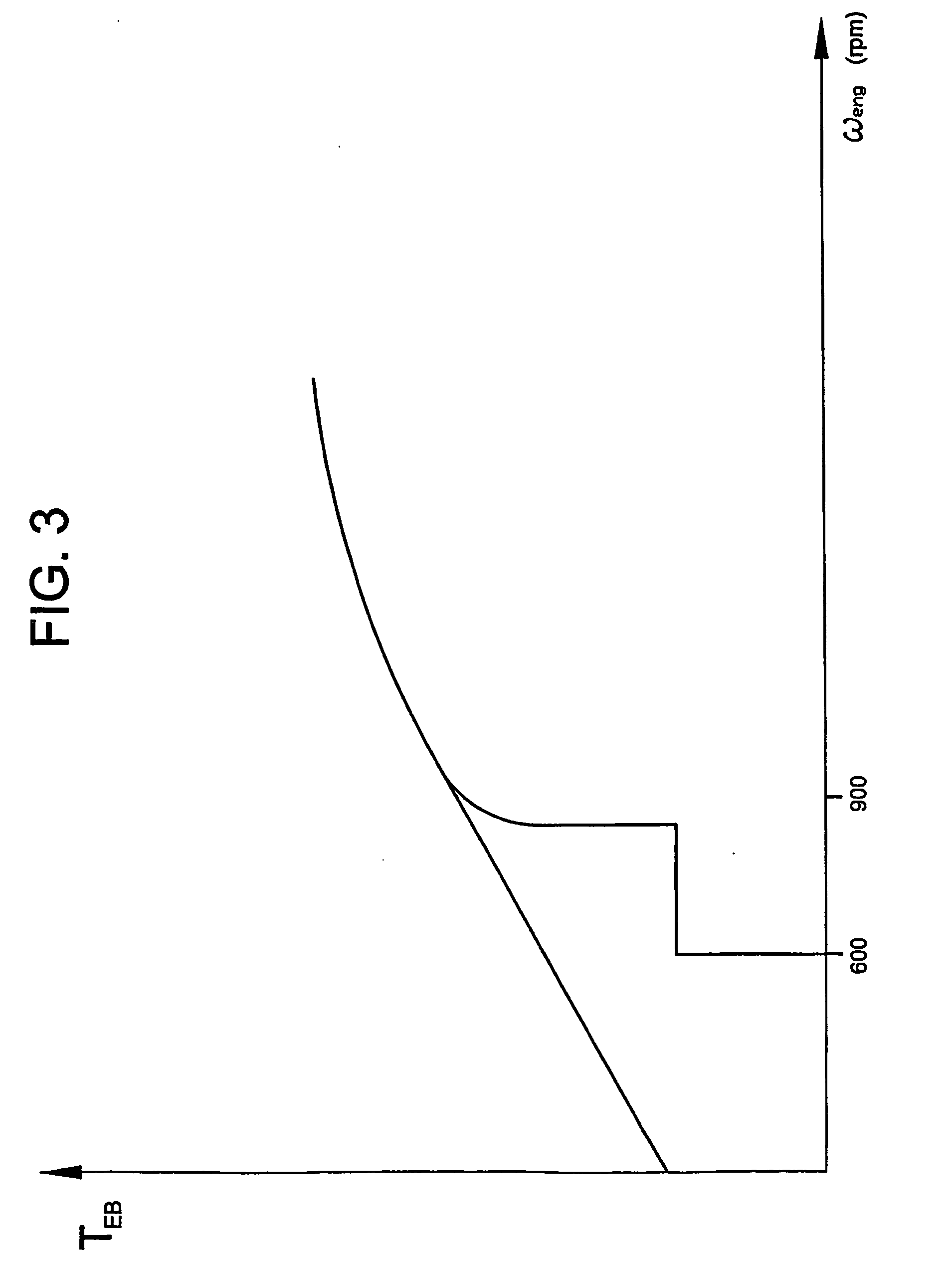

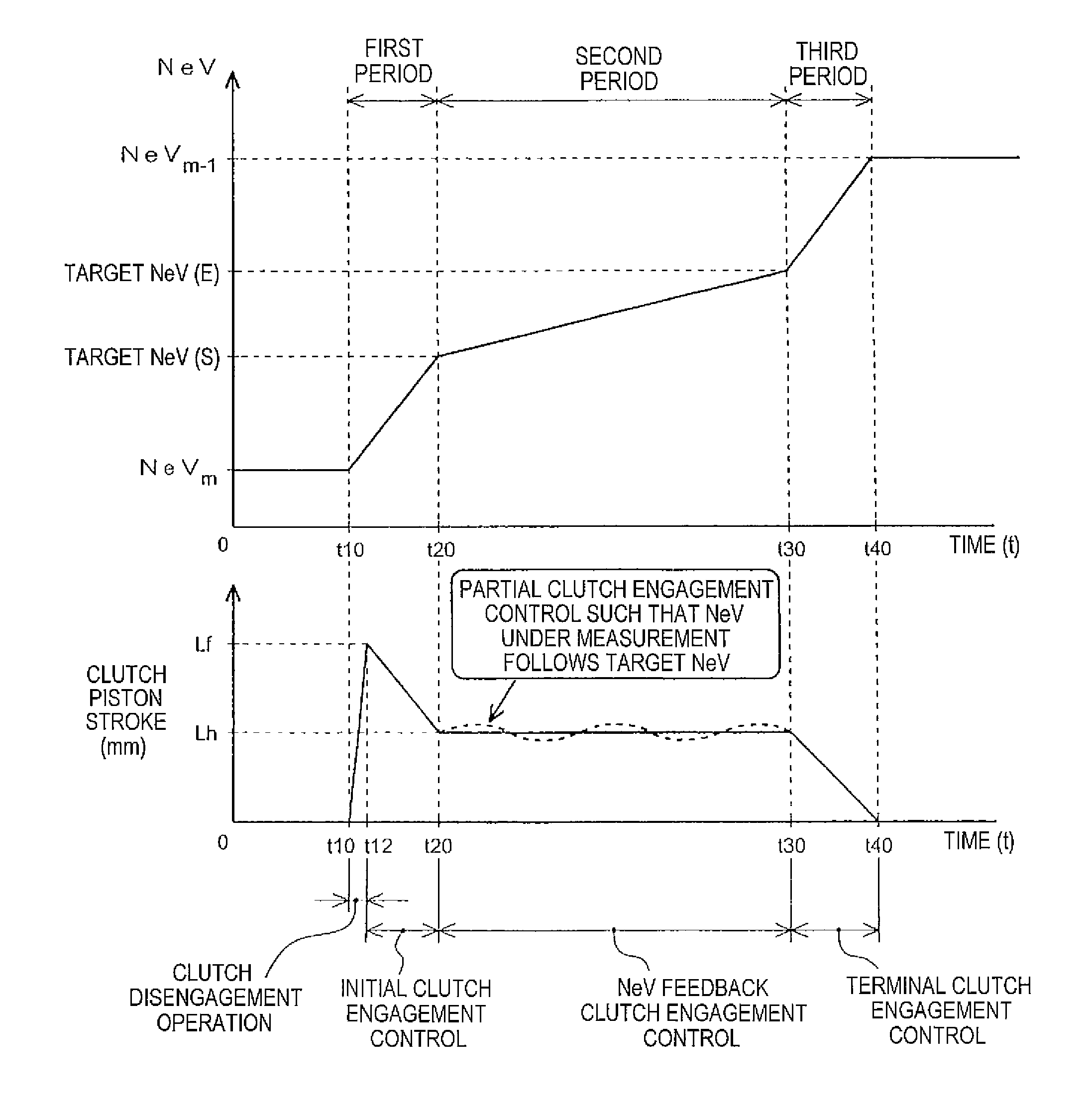

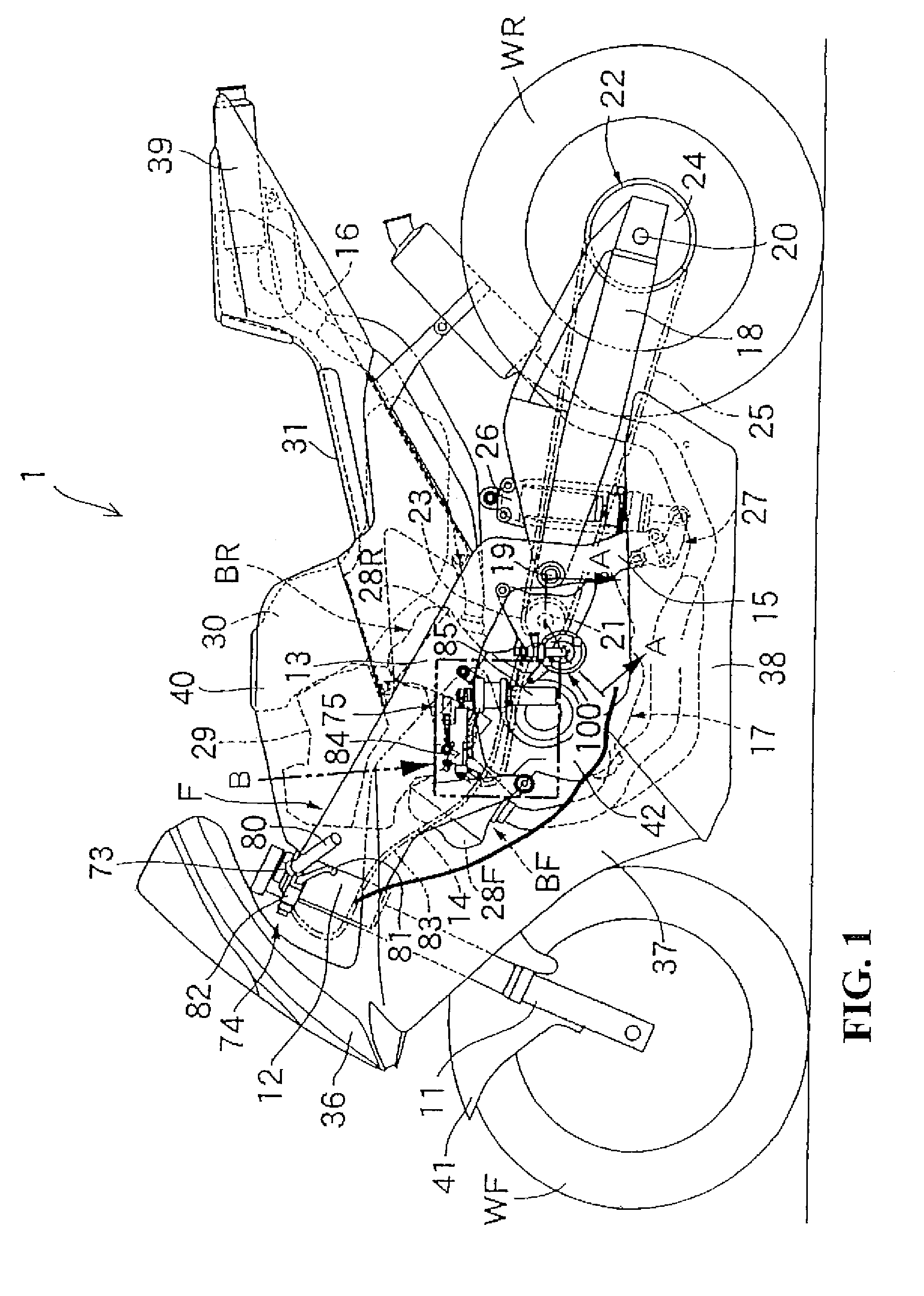

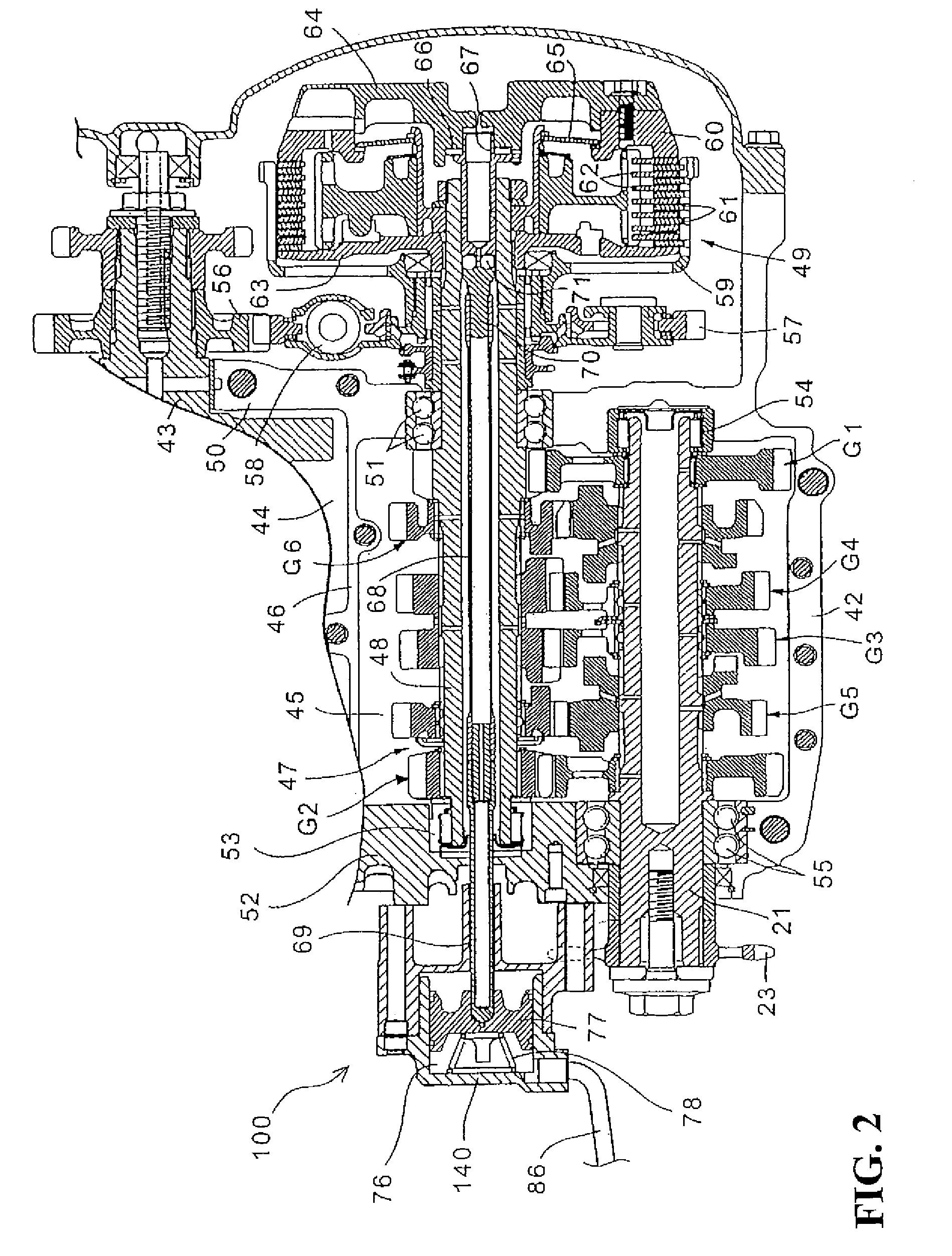

Clutch control device

ActiveUS20080182720A1Good shift shock reducing effectConstant effectFluid actuated clutchesEngine controllersClutch controlGear drive

A clutch control device for obtaining a good shift shock reducing effect regardless of a change in clutch engagement point. A target NeV database stores a target NeV map as a target value of the ratio between an engine speed (Ne) and a vehicle speed (V) obtained from the engine speed after primary speed reduction by a gear transmission. The time period from the time of detection of a downshift operation to the time of completion of the reengagement of the clutch is composed of a first period until the clutch becomes a partially engaged condition after disengagement of the clutch, a second period during which the partially engaged condition is maintained, and a third period from the time when the clutch in the partially engaged condition starts to be driven in its engaging direction to the time when the reengagement of the clutch is completed.

Owner:HONDA MOTOR CO LTD

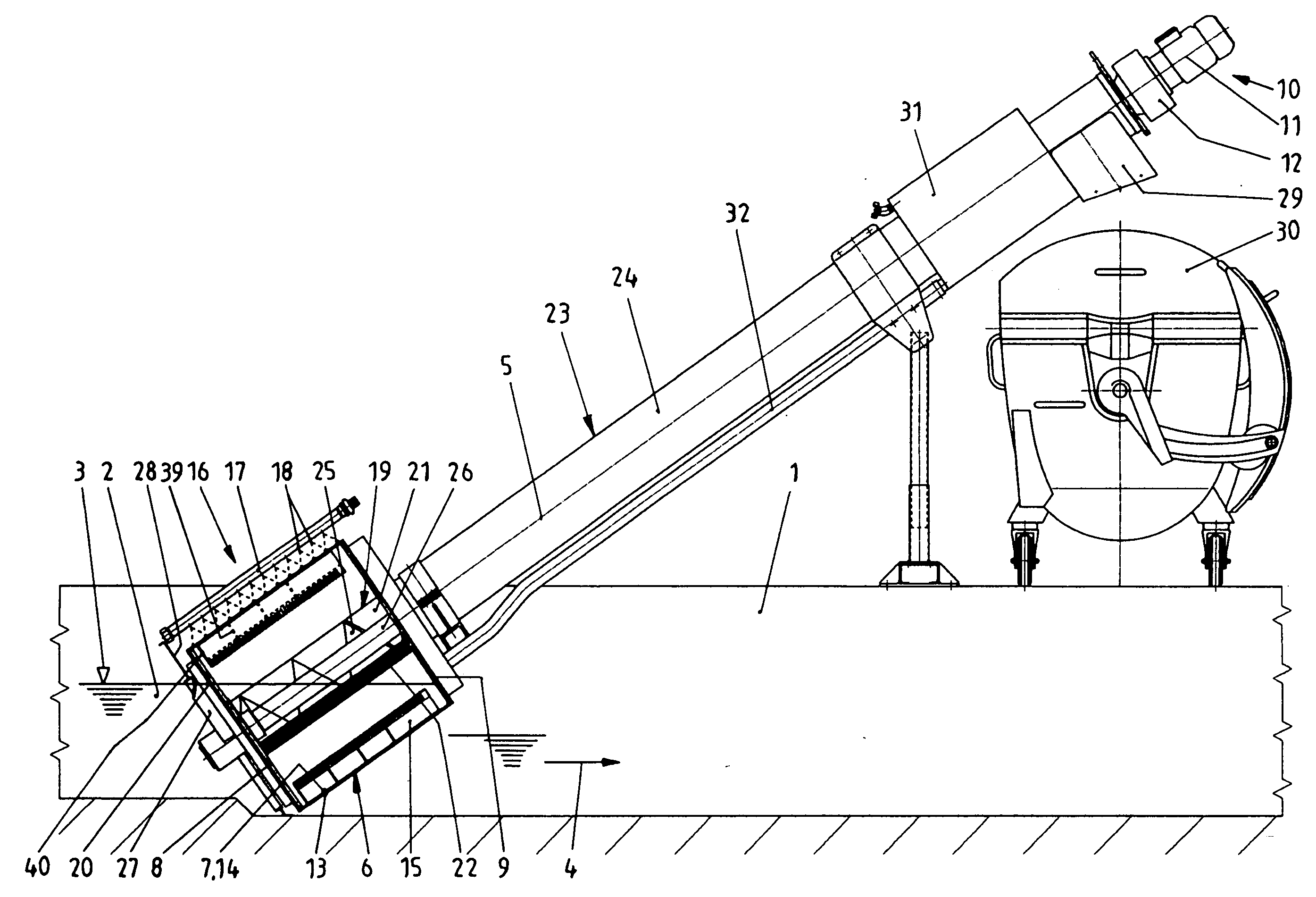

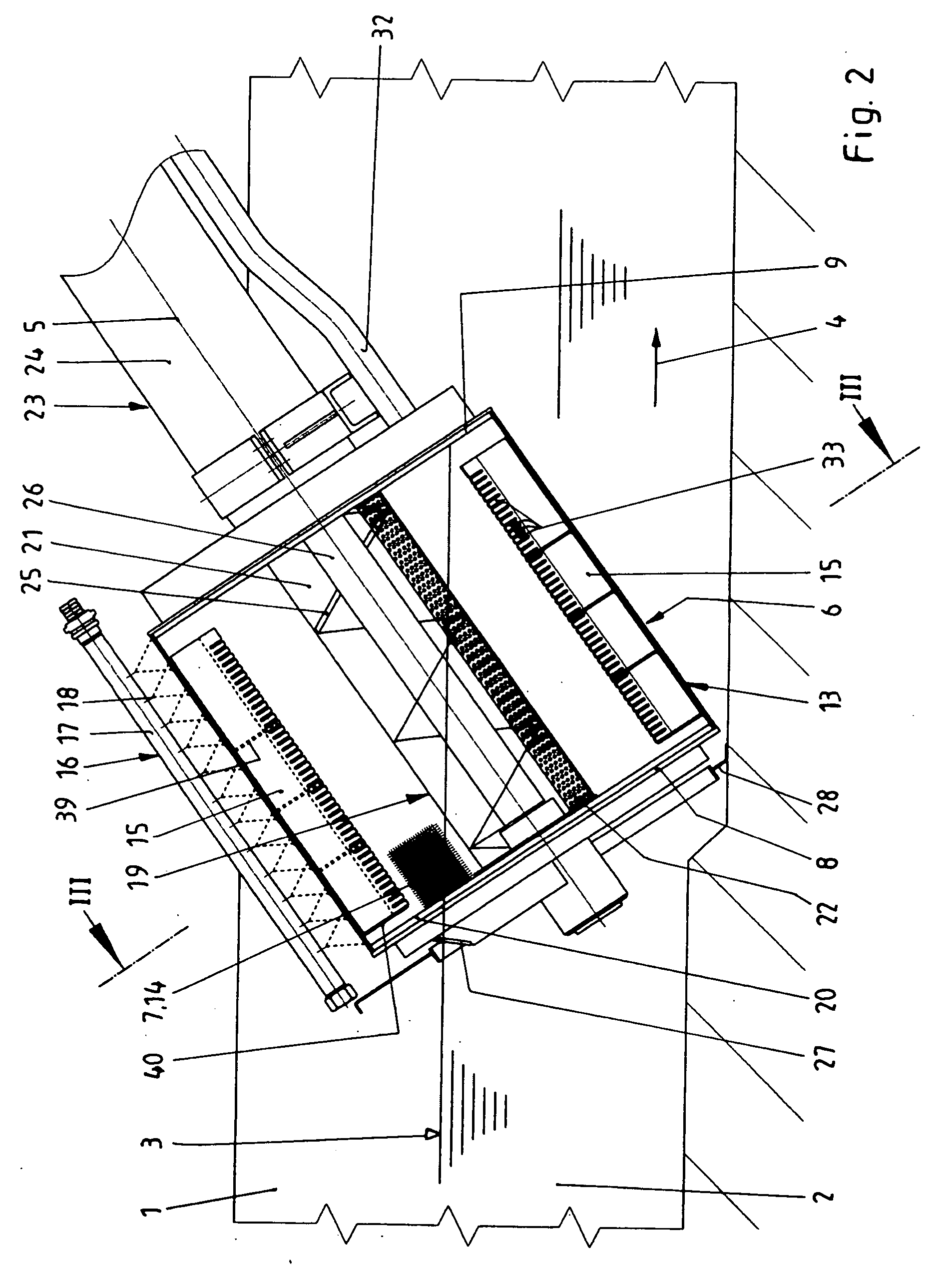

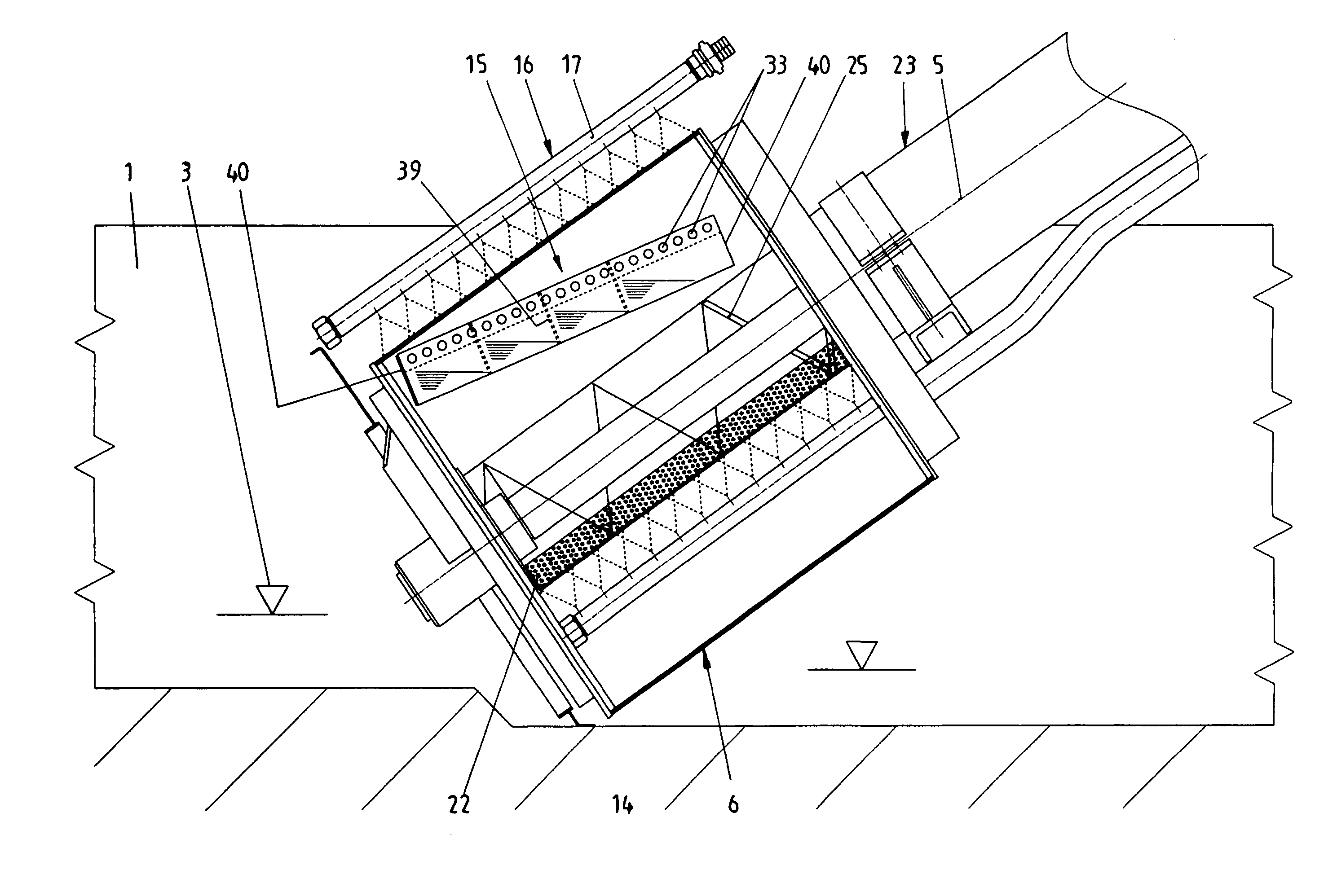

Apparatus for removing material from a liquid flowing through a channel

InactiveUS20050247610A1Economically manufacturedConstantFatty/oily/floating substances removal devicesSewerage structuresScrew conveyorSieve

An apparatus for removing material from a liquid flowing through a channel includes a sieve grate, a screw conveyor and a detaching device. The sieve grate has an inflow side, an inner side and an outer side. The sieve grate is designed to be cylindrical and to be rotatably driven. The sieve grate is arranged at an inclined orientation to be partially submerged in the liquid. The sieve grate at the inflow side includes an open face. The sieve grate at the inner side includes a plurality of guide plates. The sieve grate includes a shaping carrier element. The sieve grate includes a mesh fabric, the mesh fabric being designed and arranged to form a separation surface for the material. The screw conveyor includes a housing. The screw conveyor includes a driven conveying screw. The screw conveyor is coaxially arranged with respect to the sieve grate. The screw conveyor in the region of the sieve grate includes a feeding hopper for the material, the feeding hopper having a bottom side and including a majority of openings located in the region of the bottom side. The detaching device is arranged at the outer side of the sieve grate and above the feeding hopper in a stationary way. The detaching device is designed and arranged to detach material which adheres to the separation surface from inside of the sieve grate.

Owner:HANS HUBER MASCHEN & ANLAGENBAU

Method of manufacturing a semiconductor device and manufacturing system thereof

InactiveUS6933182B1Efficient processConstant effectTransistorSolid-state devicesHydrogenAmorphous silicon

A method of manufacturing a semiconductor device, comprises the steps of: forming an amorphous silicon film on a substrate having an insulating surface; processing said amorphous silicon film by plasma of a gas that mainly contains hydrogen or helium; and giving an energy to said amorphous silicon film.

Owner:SEMICON ENERGY LAB CO LTD

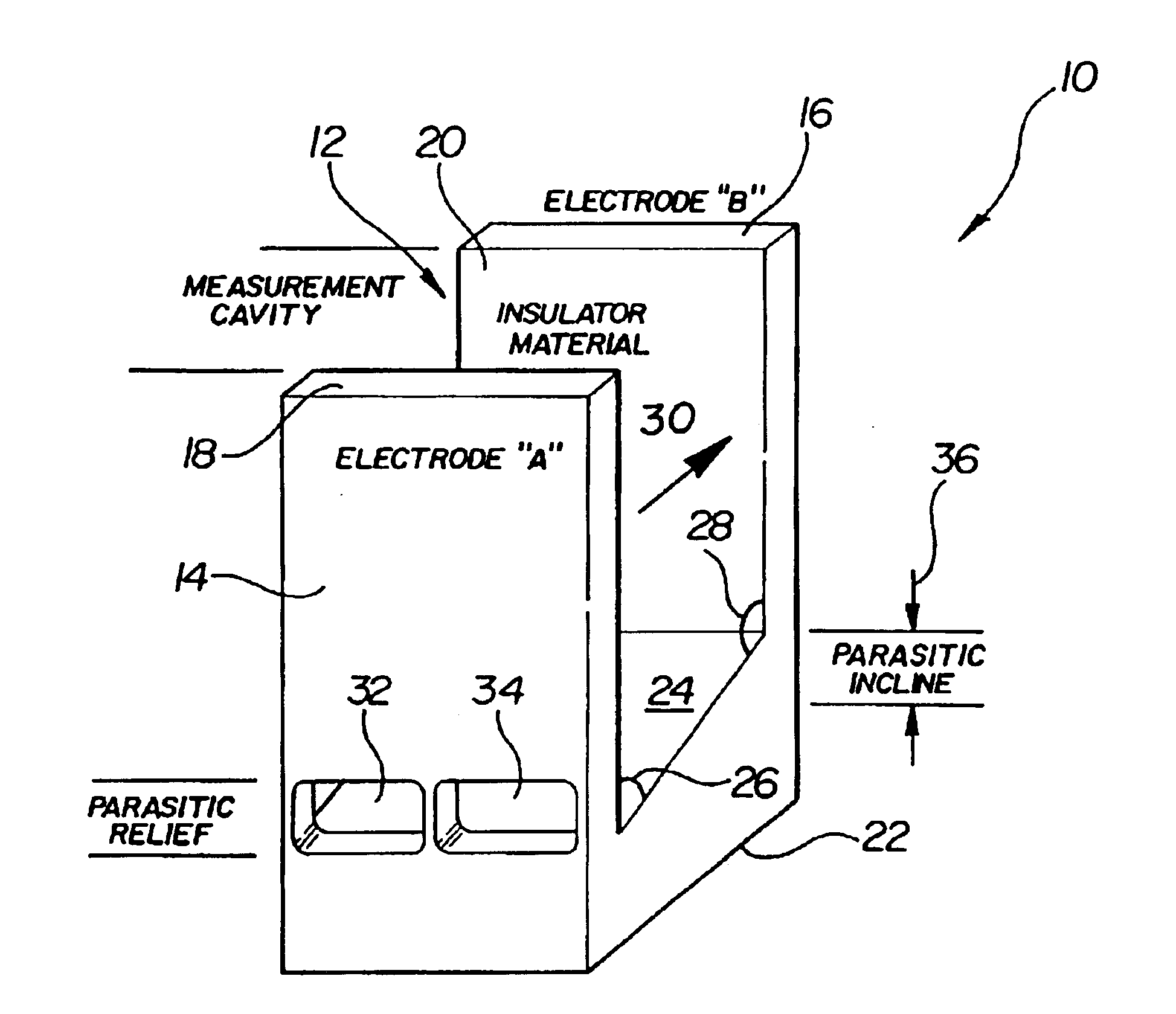

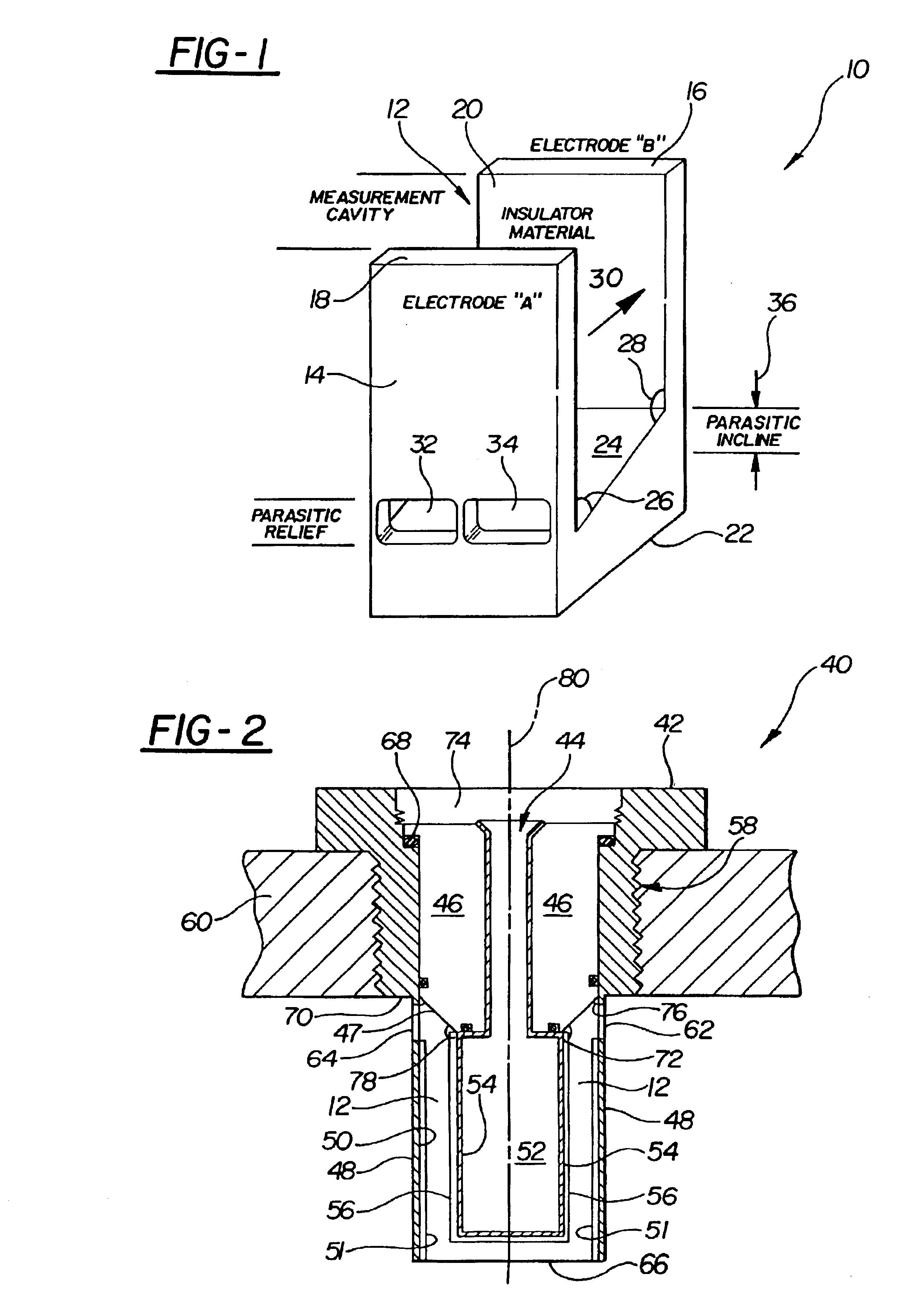

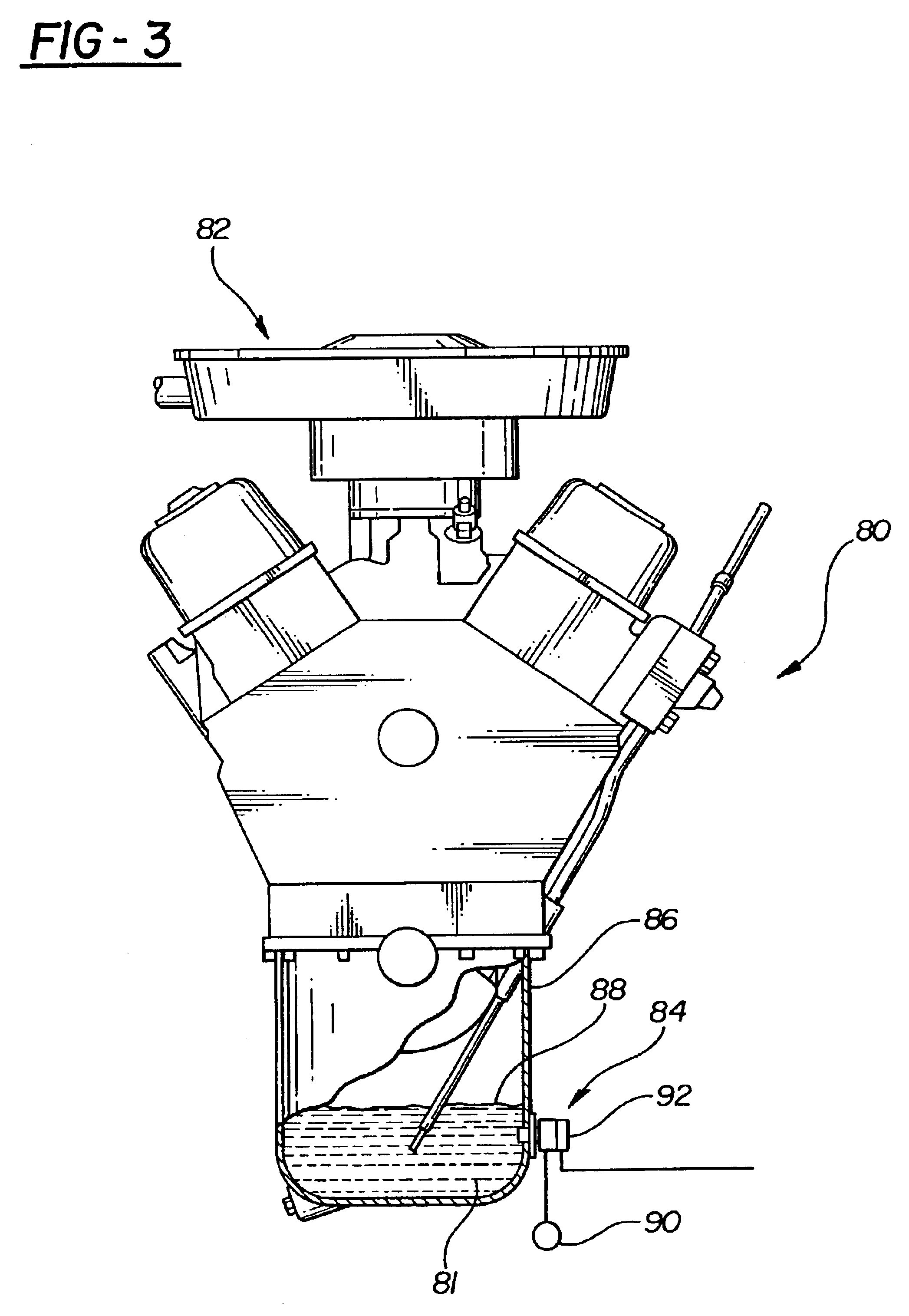

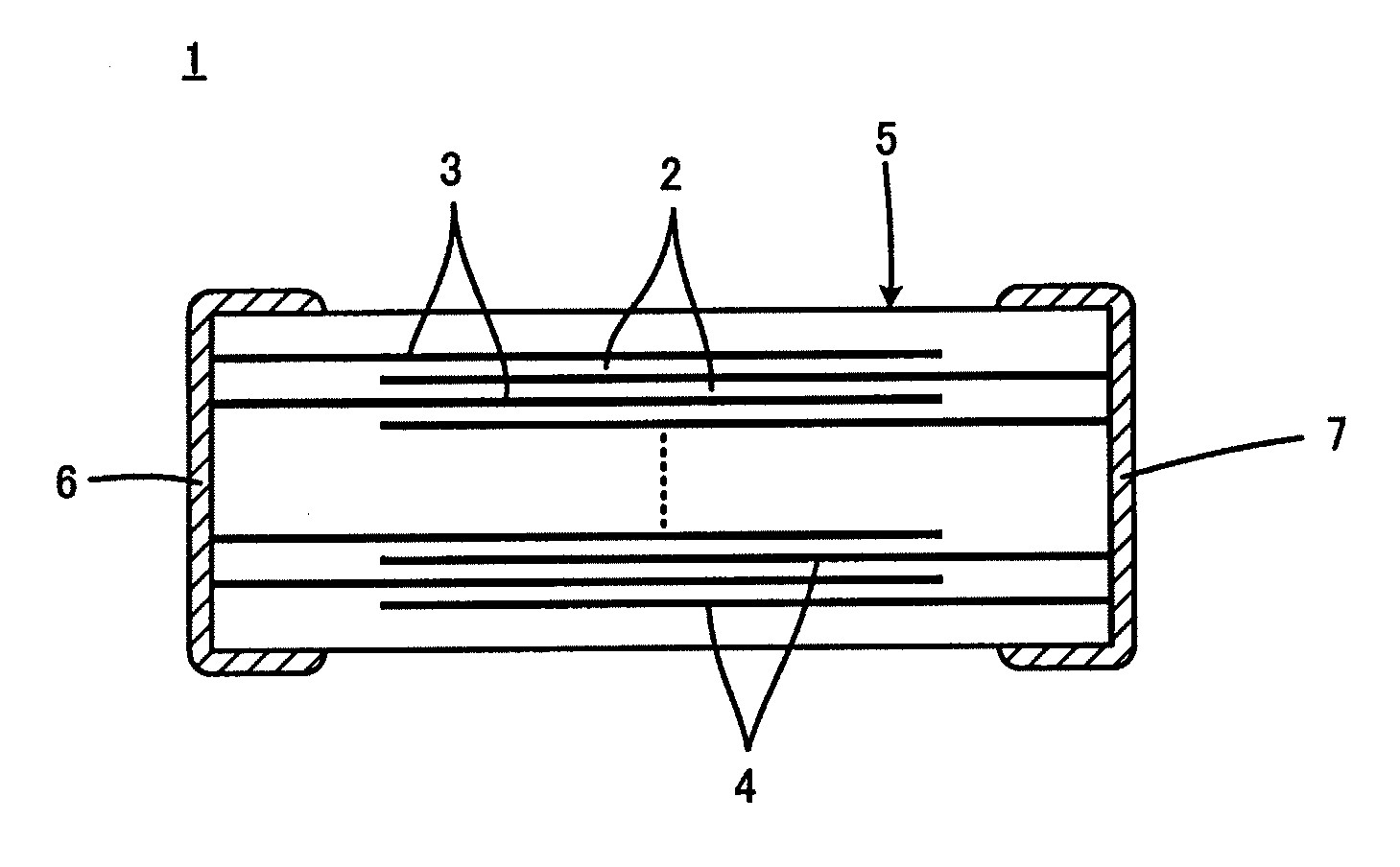

Method and apparatus for stabilizing parasitic error capacitance in oil quality sensors

InactiveUS6847216B2Reduce measurement errorReduce presenceResistance/reactance/impedenceMaterial testing goodsElectricityAcute angle

A sensor for detecting changes in the dielectric constant of a liquid is described. The sensor has two electrodes immersed in the liquid with dielectric surfaces substantially parallel with each other, and a ramp disposed on a support between the electrodes. The ramp intersects the surfaces at obtuse and acute angles respectively and provides a surface disposed at an angle relative to an electric field extending between the two electrodes, thereby reducing parasitic effects of the sensed dielectric content of the liquid. Slots in the electrode adjacent the lower end of the ramp reduce the strength of the field proximate to the ramp and thereby further reduce the parasitic effects.

Owner:DETROIT DIESEL CORP

Apparatus for removing material from a liquid flowing through a channel

InactiveUS7160443B2Easy to produceConstant cross-sectional areaFatty/oily/floating substances removal devicesSewerage structuresEngineeringScrew conveyor

An apparatus for removing material from a liquid flowing through a channel includes a sieve grate, a screw conveyor and a detaching device. The sieve grate has an inflow side, an inner side and an outer side. The sieve grate is designed to be cylindrical and to be rotatably driven. The sieve grate is arranged at an inclined orientation to be partially submerged in the liquid. The sieve grate at the inflow side includes an open face. The sieve grate at the inner side includes a plurality of guide plates. The sieve grate includes a shaping carrier element. The sieve grate includes a mesh fabric, the mesh fabric being designed and arranged to form a separation surface for the material. The screw conveyor includes a housing. The screw conveyor includes a driven conveying screw. The screw conveyor is coaxially arranged with respect to the sieve grate. The screw conveyor in the region of the sieve grate includes a feeding hopper for the material, the feeding hopper having a bottom side and including a majority of openings located in the region of the bottom side. The detaching device is arranged at the outer side of the sieve grate and above the feeding hopper in a stationary way. The detaching device is designed and arranged to detach material which adheres to the separation surface from inside of the sieve grate.

Owner:HANS HUBER MASCHEN & ANLAGENBAU

Scan signal transmission system and method thereof

InactiveUS20110254830A1Constant effectEliminate the effects ofCathode-ray tube indicatorsInput/output processes for data processingDisplay deviceEngineering

A scan signal transmission system and a method thereof are provided, which are applicable to a display device. The system includes a display area circuit and a gate circuit, the display area circuit has a plurality of pixel scan lines, and the gate circuit is connected to each of the pixel scan lines. The gate circuit is used for obtaining a scan signal from a clock generator, so as to transmit the scan signal to each of the pixel scan lines sequentially. During each frame scan operation, the gate circuit transmits the scan signal to the pixel scan lines in a reverse signal transmission direction.

Owner:CHUNGHWA PICTURE TUBES LTD

Plant Quality Improver and Process for Producing the Same

ActiveUS20080153703A1Effective absorptionGood dispersionSuperphosphatesBiocideOrganic acidPhosphate ion

A sparingly water-soluble plant quality improver characterized by containing a polyvalent metal, an organic acid having a carboxylic group, an alkali metal and / or ammonia, and phosphate ions and / or carbonate ions. The sparingly water-soluble plant quality improver inhibits or alleviates physiological disorders of plants and further has the function of improving qualities of the plants, such as sugar content and acidity. It is also characterized in that it causes little fruit surface soiling to heighten the merchandice value, and that it is lowly phytotoxic and highly safe.

Owner:MARUO CALCIUM COMPANY

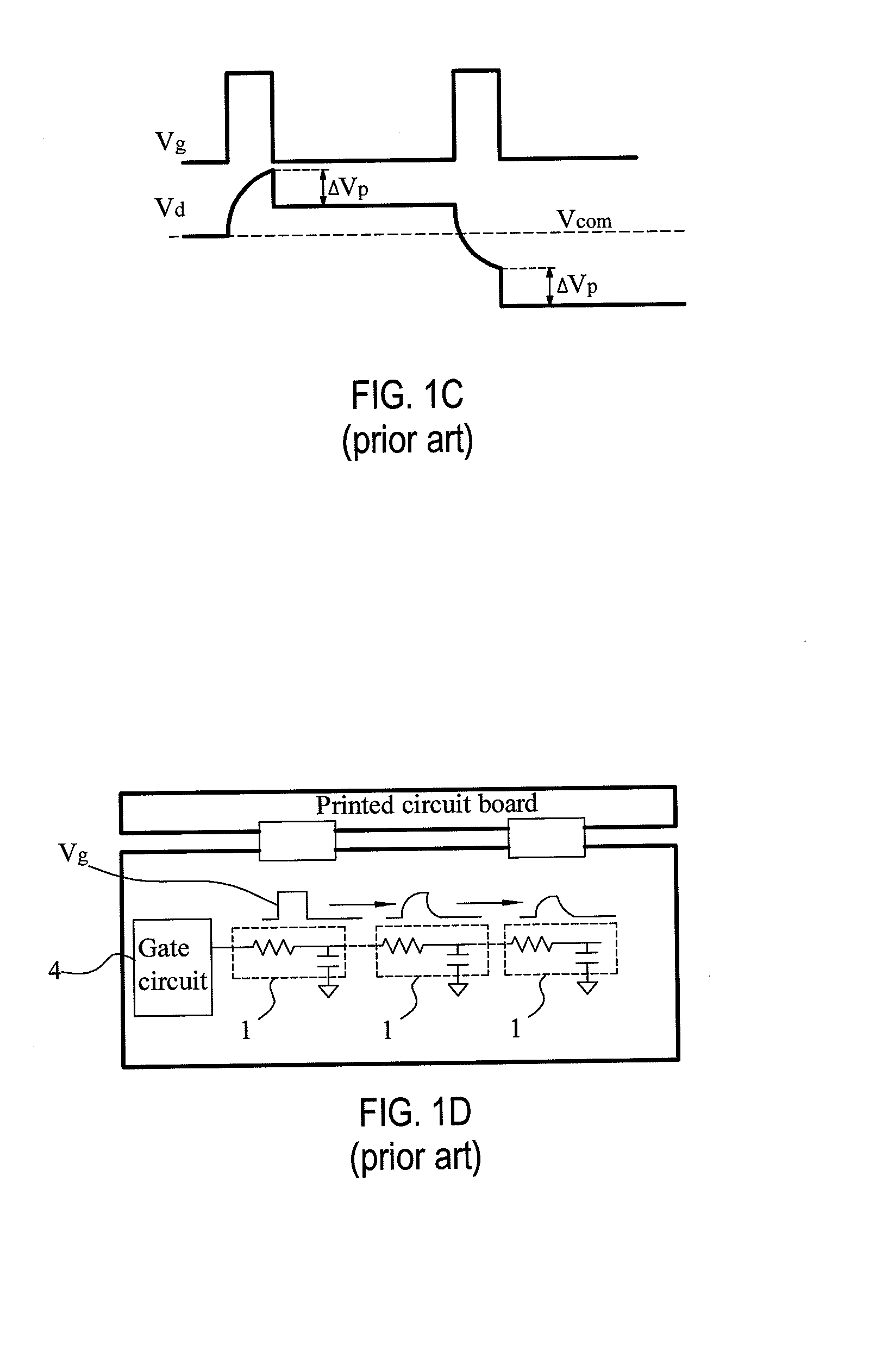

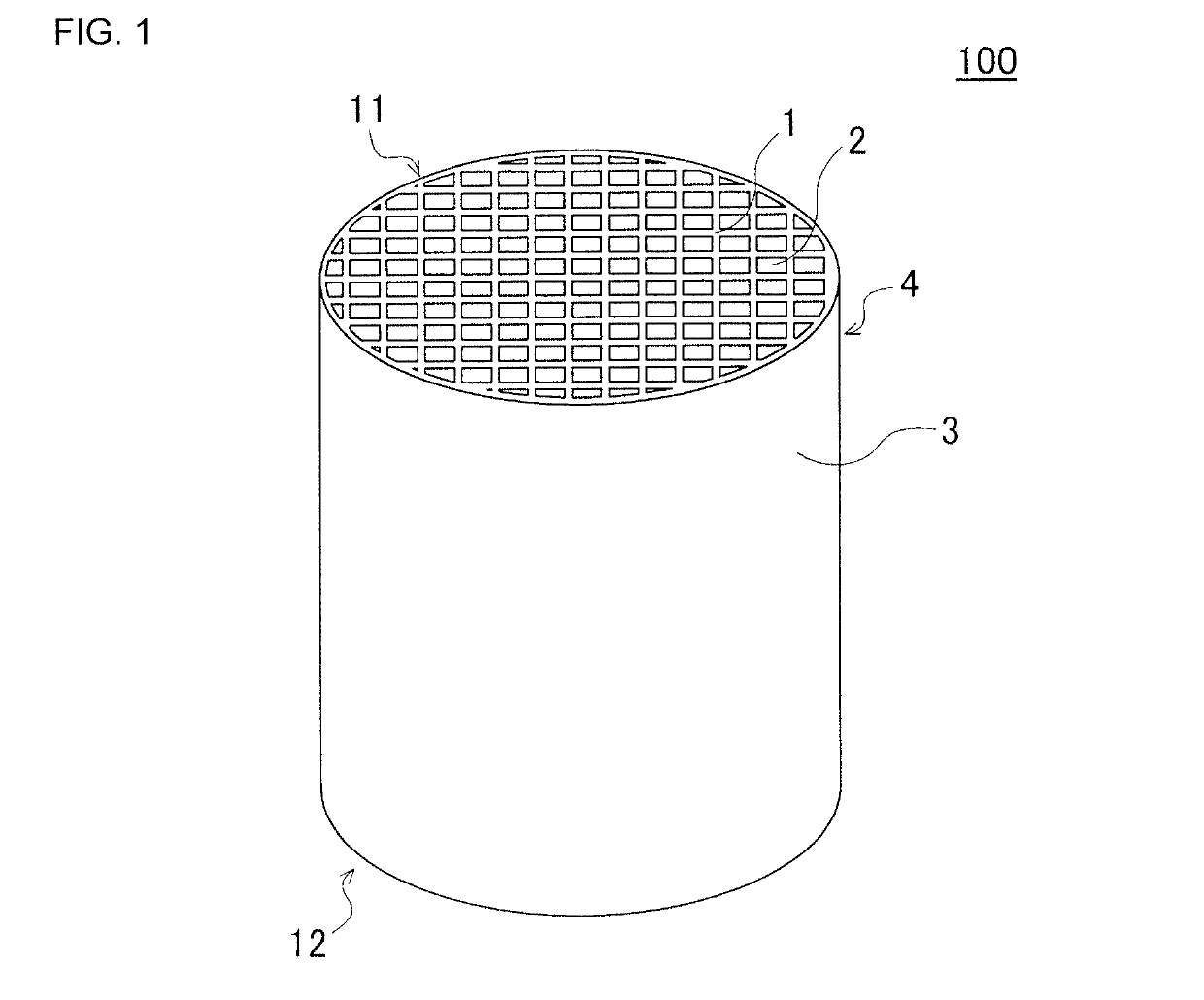

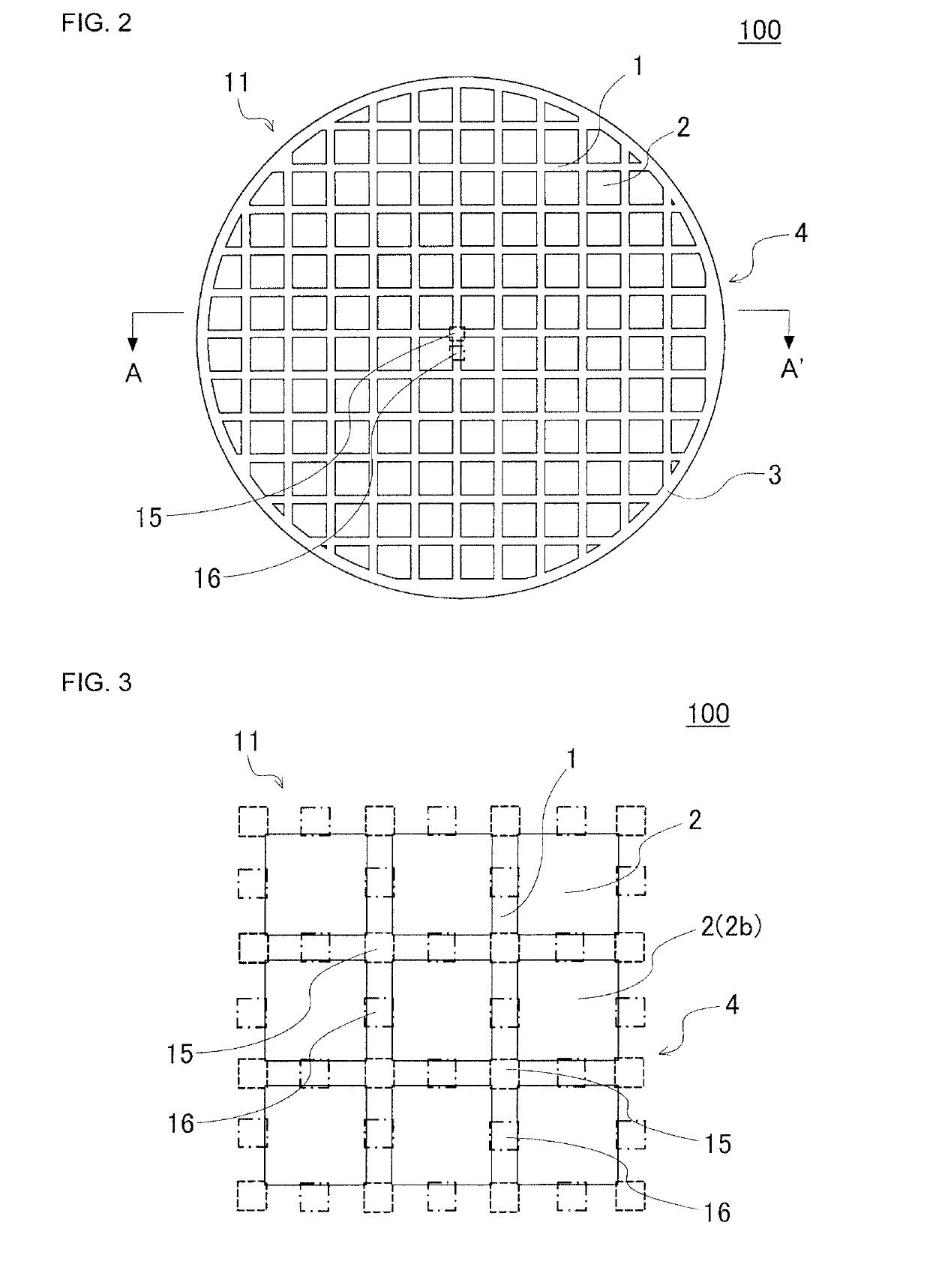

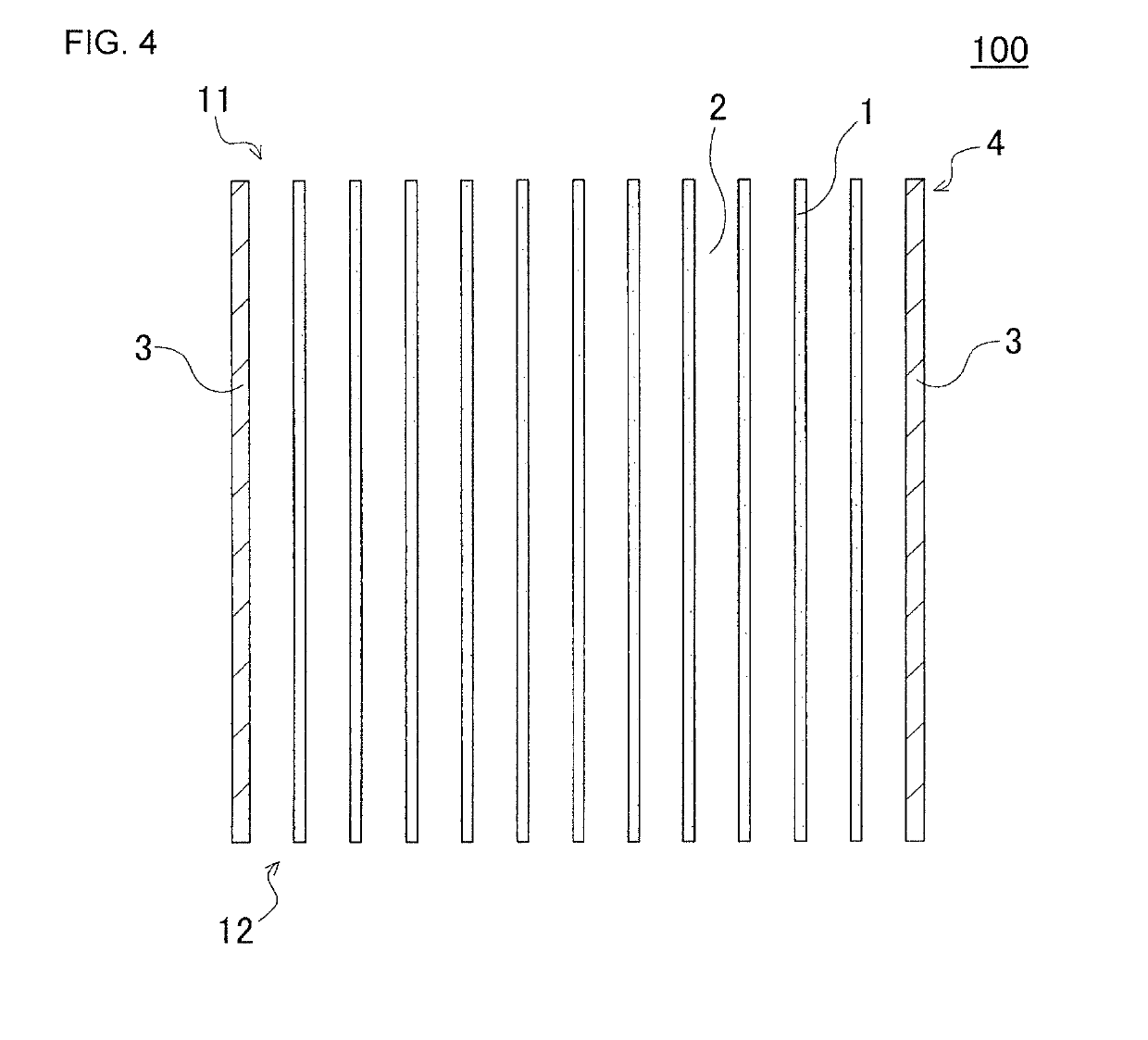

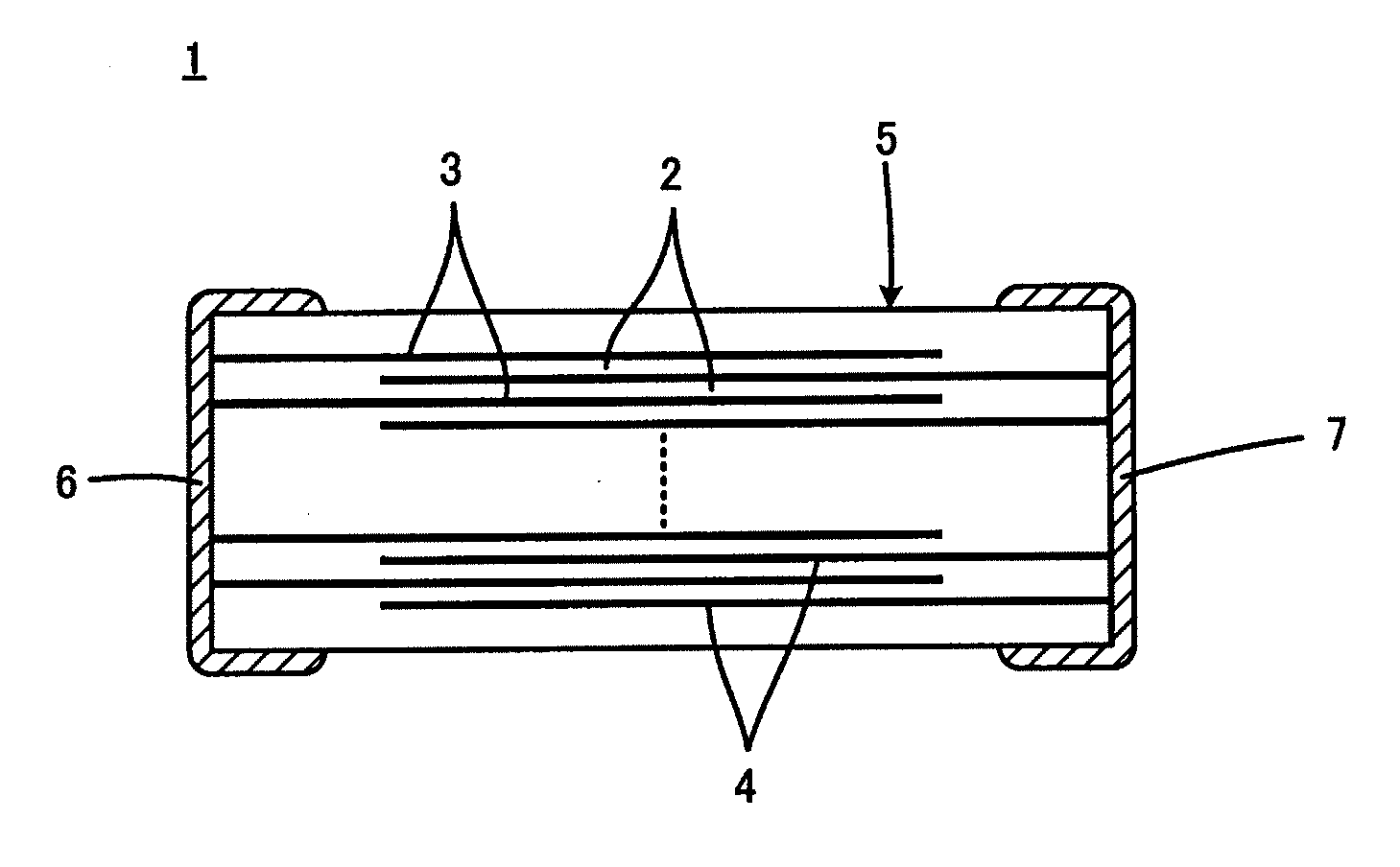

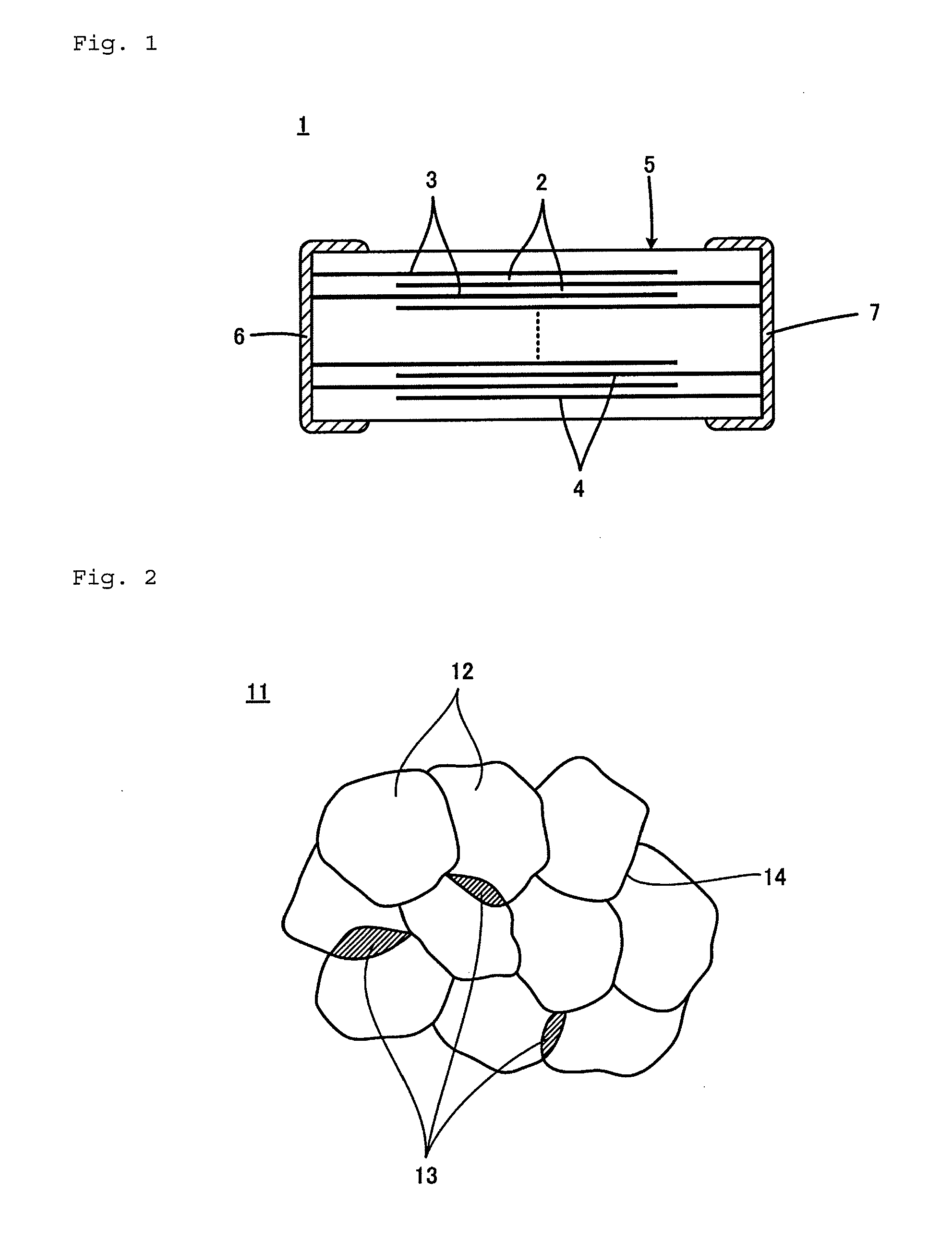

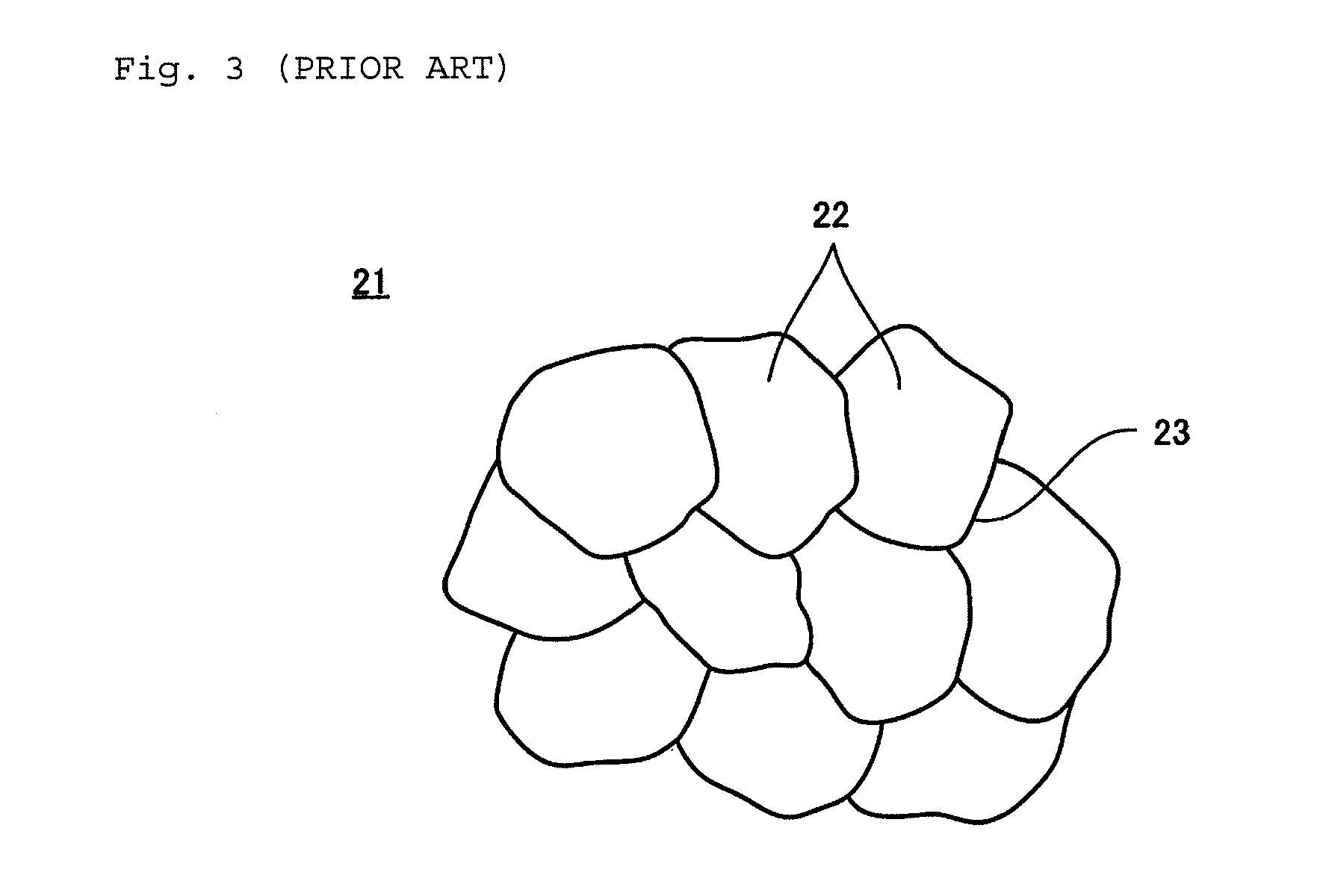

Honeycomb structure

ActiveUS20190160456A1Improve thermal shock resistanceInhibit the generation of cracksPhysical/chemical process catalystsDispersed particle separationPorosityHoneycomb structure

A honeycomb structure includes a honeycomb structure body having porous partition walls, wherein a value of a porosity of the partition wall in a partitioning wall portion between the two cells is defined as a porosity A, a value of a porosity of the partition wall in an intersecting portion that is a region connecting two or more wall portions is defined as a porosity B, a value of A / B obtained by dividing the porosity A by the porosity B is from 0.5 to 0.95, and the porosity A is from 10 to 40%.

Owner:NGK INSULATORS LTD

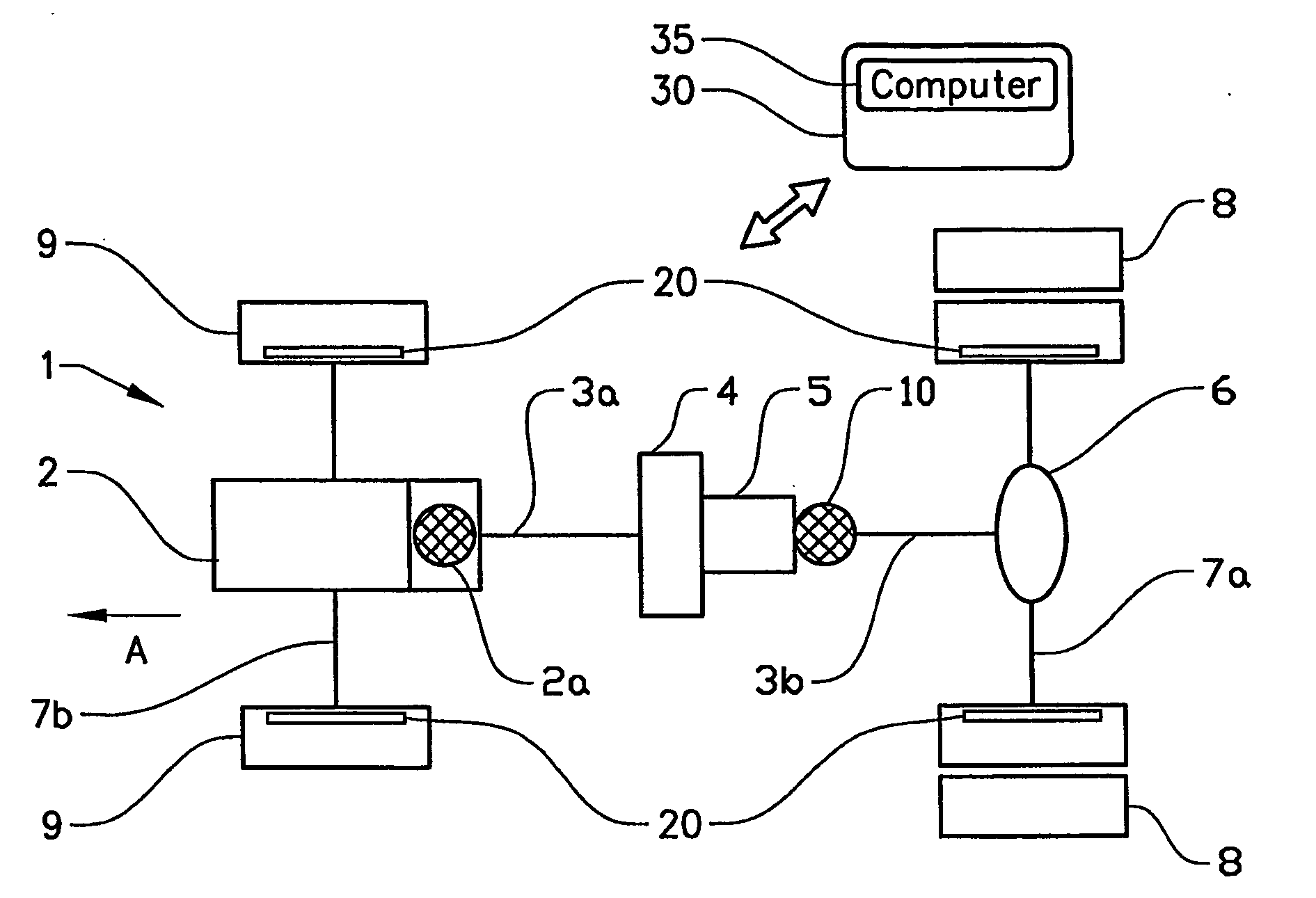

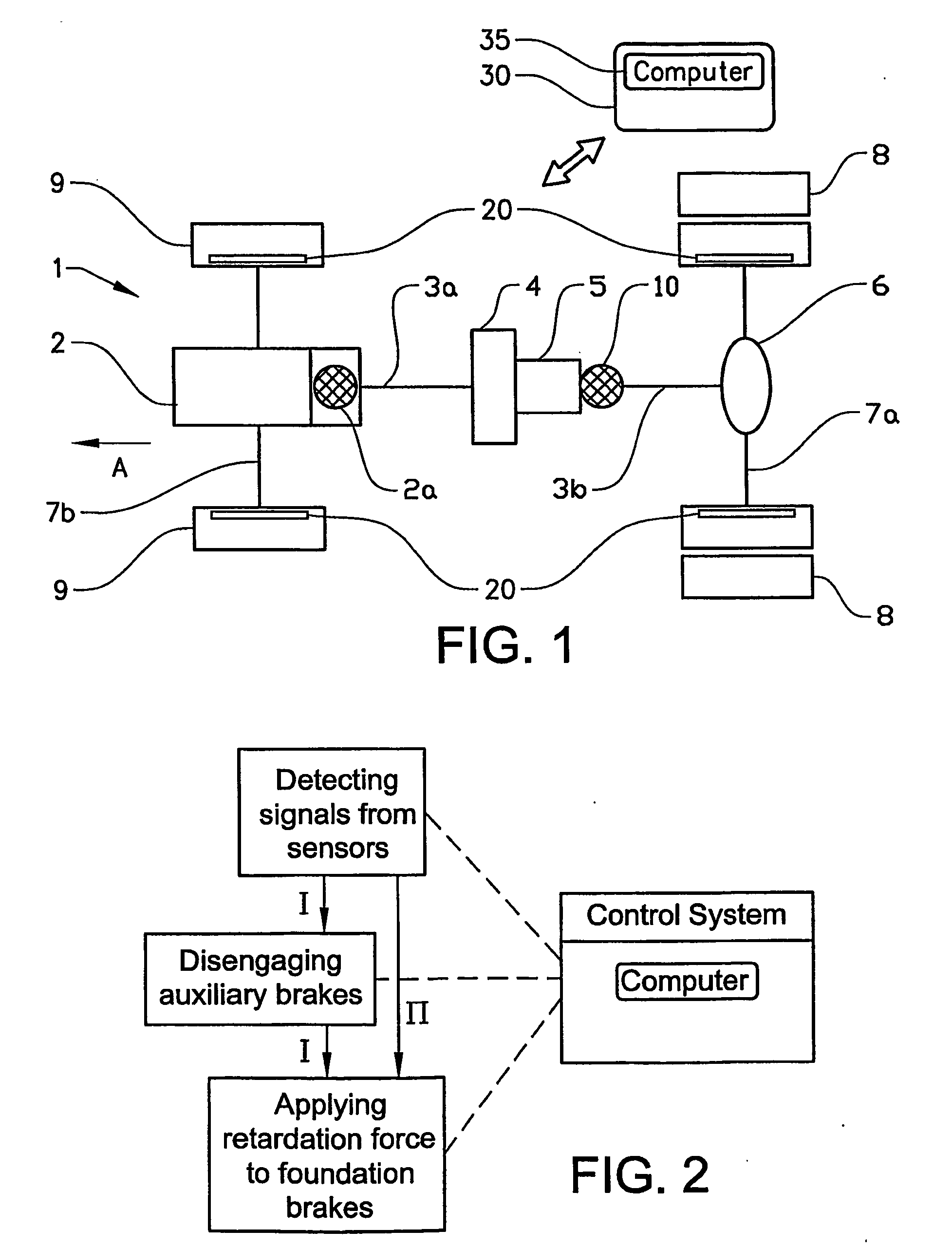

Retarder slip control

InactiveUS20100033008A1Eliminate uncomfortable “ slip ” of braking effectEffective brakingHydrodynamic brakesBrake safety systemsDrive wheelControl system

A motor vehicle fitted with a control system for applying braking effect to foundation brakes acting on each wheel of the vehicle, when the braking effect provided by auxiliary brakes, acting on the driven wheels, is lost or significantly reduced is described. Sudden loss of auxiliary brake force can be felt as very bad drivability of the vehicle, a situation that typically occurs in case of low friction between road and tires or if the auxiliary brakes are down controlled to avoid engine stop. By use of a control system, these situations can be avoided. The control system includes a sensor, and a computer for computing and applying the braking effect to the foundation brakes to compensate for the loss of auxiliary braking force. Disclosed is also a method for applying braking effect to the foundation brakes of a motor vehicle.

Owner:VOLVO LASTVAGNAR AB

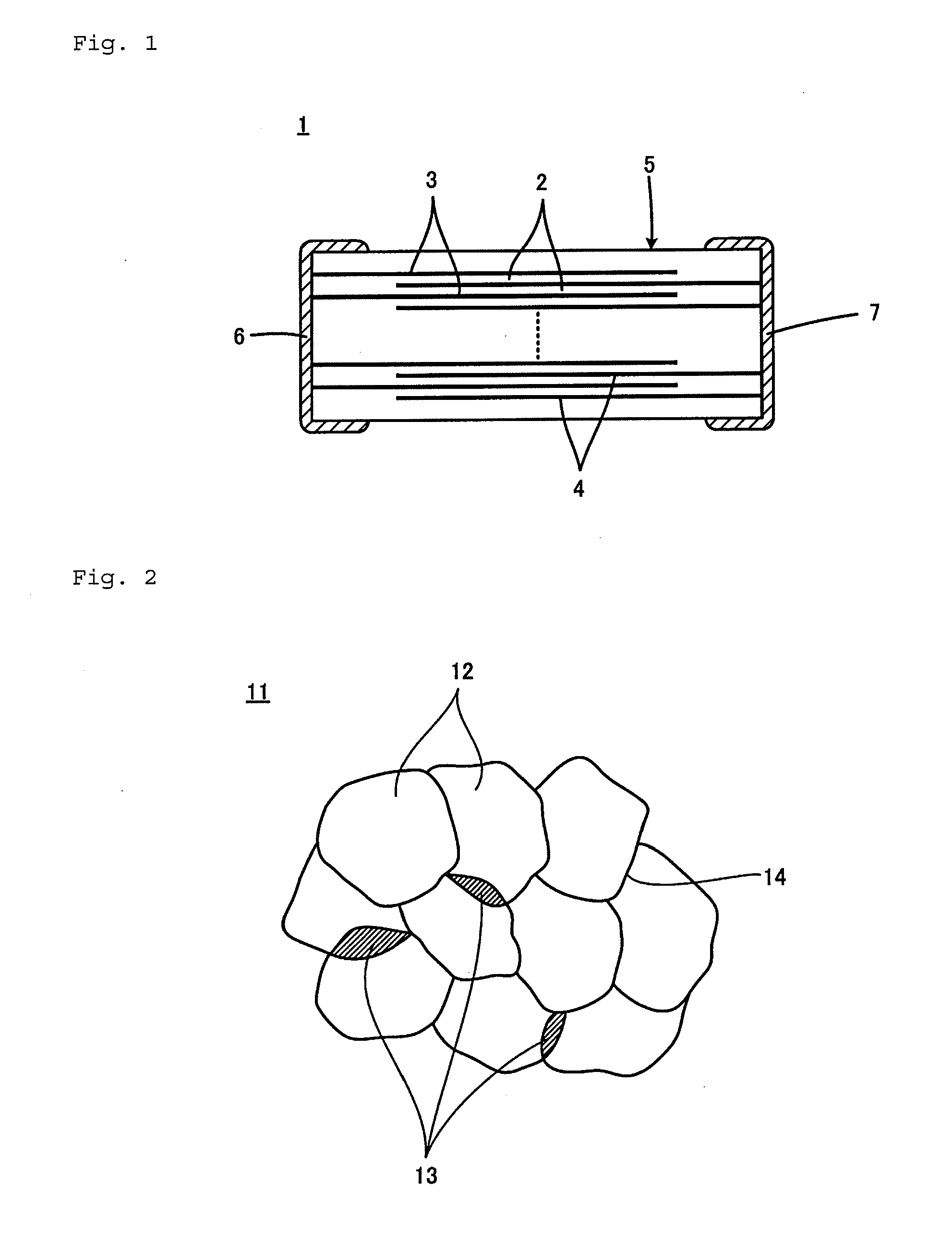

Dielectric ceramic and laminated ceramic capacitor

ActiveUS20100195260A1High dielectric constantReduce in quantityMaterial nanotechnologyFixed capacitor electrodesDielectricCeramic capacitor

A dielectric ceramic containing ABO3 in which A is Ba, possibly with at least one of Ca and Sr, and B is Ti, possibly with at least one of Zr and Hf as its main component, and Si as a accessory component. The dielectric ceramic includes main phase grains containing the ABO3 main component and secondary phase grains having a composition different from that of the main phase grains. The ratio of the Si content in the secondary phase grains to the total content of Si in the dielectric ceramic is 40% or more so that more Si is distributed in the secondary phase grains. It is preferable that the Si content in secondary phase grains be 30 mol% or more.

Owner:MURATA MFG CO LTD

Clutch control device

ActiveUS8360930B2Good shift shock reducing effectConstant effectFluid actuated clutchesEngine controllersClutch controlEngineering

A clutch control device for obtaining a good shift shock reducing effect regardless of a change in clutch engagement point. A target NeV database stores a target NeV map as a target value of the ratio between an engine speed (Ne) and a vehicle speed (V) obtained from the engine speed after primary speed reduction by a gear transmission. The time period from the time of detection of a downshift operation to the time of completion of the reengagement of the clutch is composed of a first period until the clutch becomes a partially engaged condition after disengagement of the clutch, a second period during which the partially engaged condition is maintained, and a third period from the time when the clutch in the partially engaged condition starts to be driven in its engaging direction to the time when the reengagement of the clutch is completed.

Owner:HONDA MOTOR CO LTD

Particulate plant treatment composition

A sparingly water-soluble plant quality improver characterized by containing a polyvalent metal, an organic acid having a carboxylic group, an alkali metal and / or ammonia, and phosphate ions and / or carbonate ions. The sparingly water-soluble plant quality improver inhibits or alleviates physiological disorders of plants and further has the function of improving qualities of the plants, such as sugar content and acidity. It is also characterized in that it causes little fruit surface soiling to heighten the merchandice value, and that it is lowly phytotoxic and highly safe.

Owner:MARUO CALCIUM COMPANY

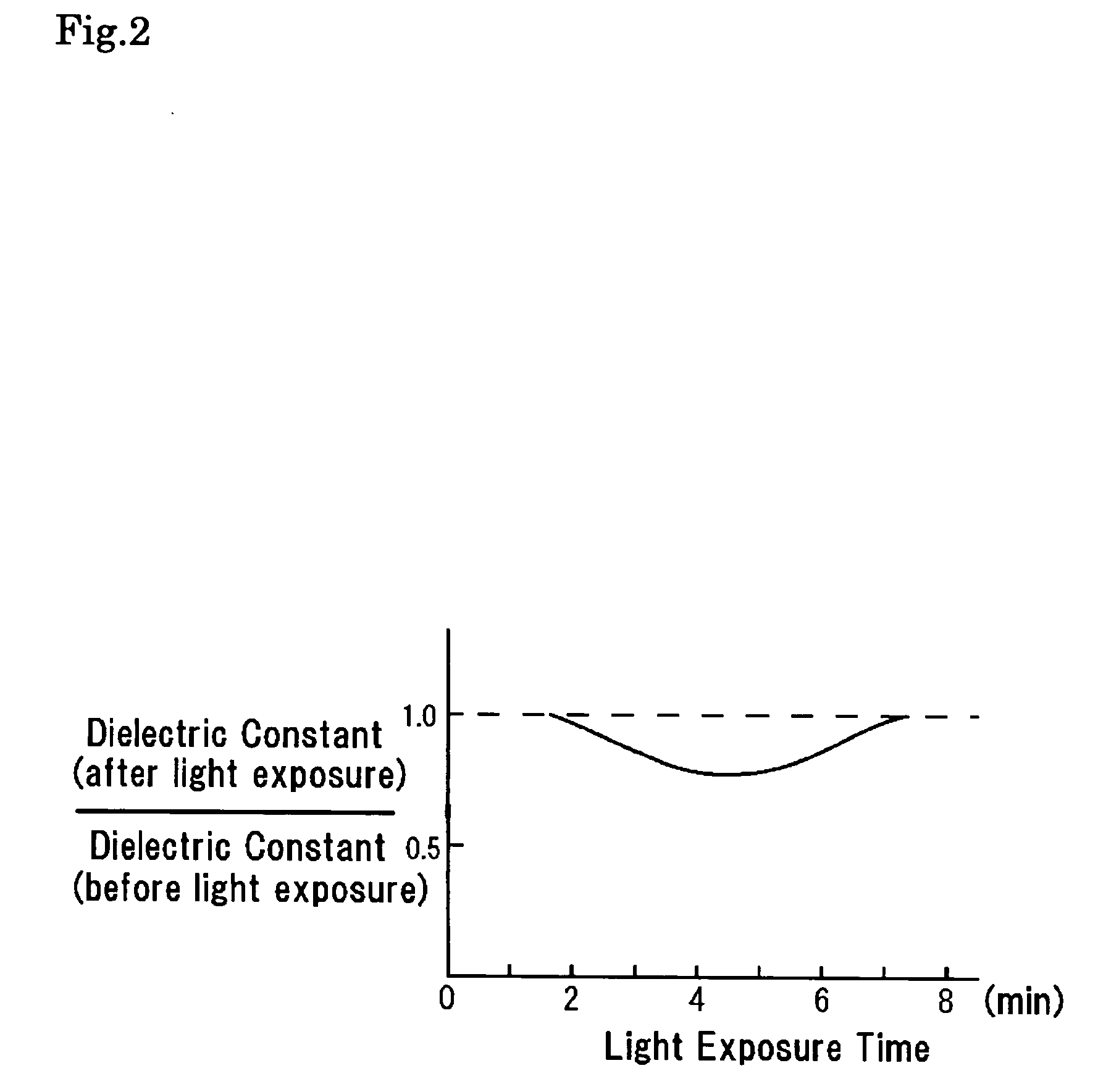

Method and apparatus for forming low permittivity film and electronic device using the film

InactiveUS20050064724A1High dielectric constantConstant effectSemiconductor/solid-state device manufacturingChemical vapor deposition coatingUltravioletPermittivity

A film formation method enables the creation of a low dielectric constant boron-carbon-nitrogen thin film. The film formation method includes the steps of generating plasma in a film formation chamber, reacting boron and carbon with nitrogen atoms inside the film formation chamber, forming a boron-carbon-nitrogen film on a substrate, and thereafter subjecting the formed film to light exposure (e.g., ultraviolet and / or infrared).

Owner:SUGINO TAKASHI +2

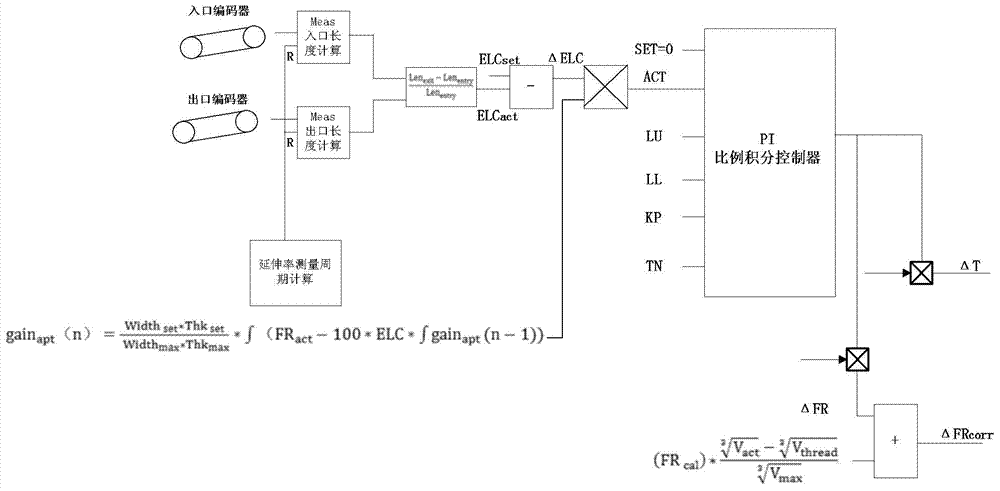

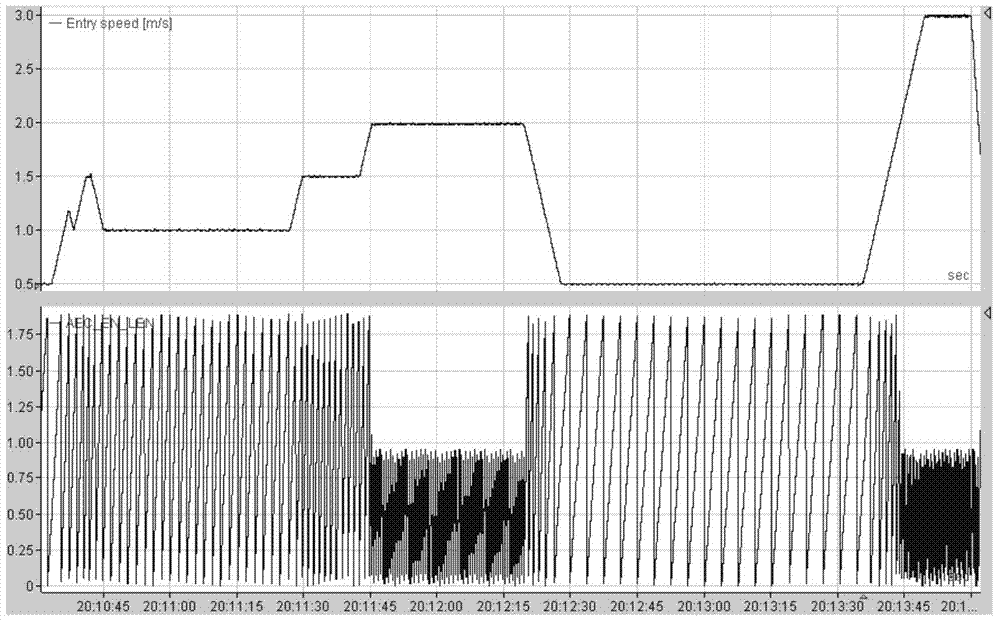

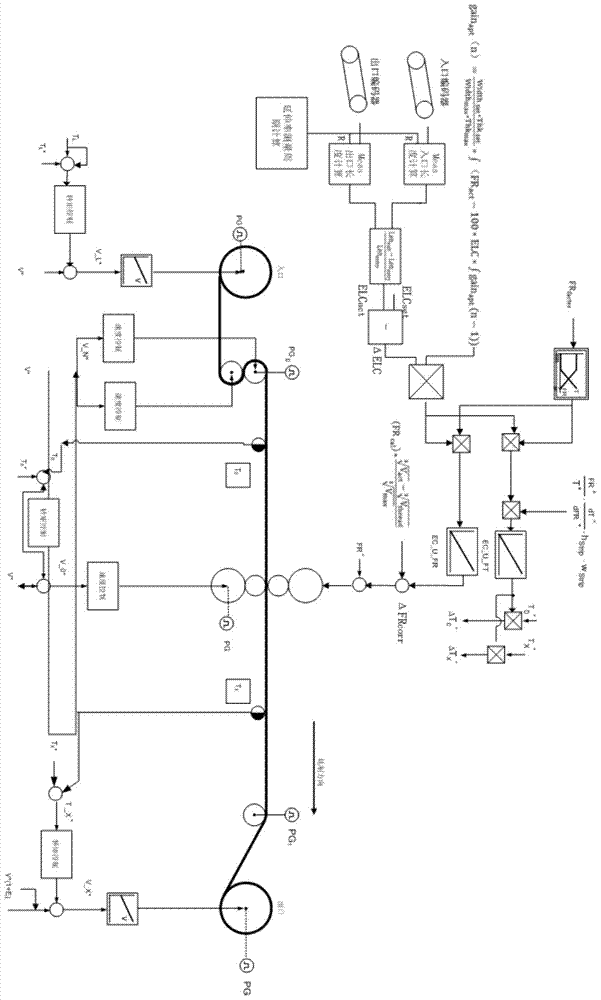

Method for obtaining constant elongation in states of acceleration and deceleration

ActiveCN104492823ASolve the problem of control accuracySolve slippageRare end control deviceRoll force/gap control deviceControl mannerEngineering

The invention provides a method for obtaining constant elongation in states of acceleration and deceleration. The method comprises the following steps of respectively acquiring the speed of strip steel of an entrance and the speed of strip steel of an exit; setting a length-variable calculating period; calculating an actual value of the elongation; comparing the actual value of the elongation to a setting value of the elongation to obtain an elongation difference value; using a product of the elongation difference value and an elongation adaptive adjustment factor as an inputting value of a PI (proportional integral) controller; outputting additional controlled quantity of a rolling force control ring and additional controlled quantity of a tension control ring; and superposing the additional controlled quantity of the rolling force control ring, the additional controlled quantity of the tension control ring and a rolling force adaptive adjustment factor to obtain final rolling force adjustment amount. Elongation length calculating periods are set at different speed sections, so that the problem of slipping of strip steel in processes of acceleration and deceleration can be solved. By correlation operation of three-times extraction of a square root of actual speed, elongation fluctuation adjustment in the processes of acceleration and deceleration is accelerated in a feedforward control manner; and adaptive factors are set according to dynamic correction of errors of an actual rolling force and an elongation expected rolling force and relation of thickness, width and elongation, and the control precision and the stability of the elongation in the processes of acceleration and deceleration are improved.

Owner:WISDRI WUHAN AUTOMATION

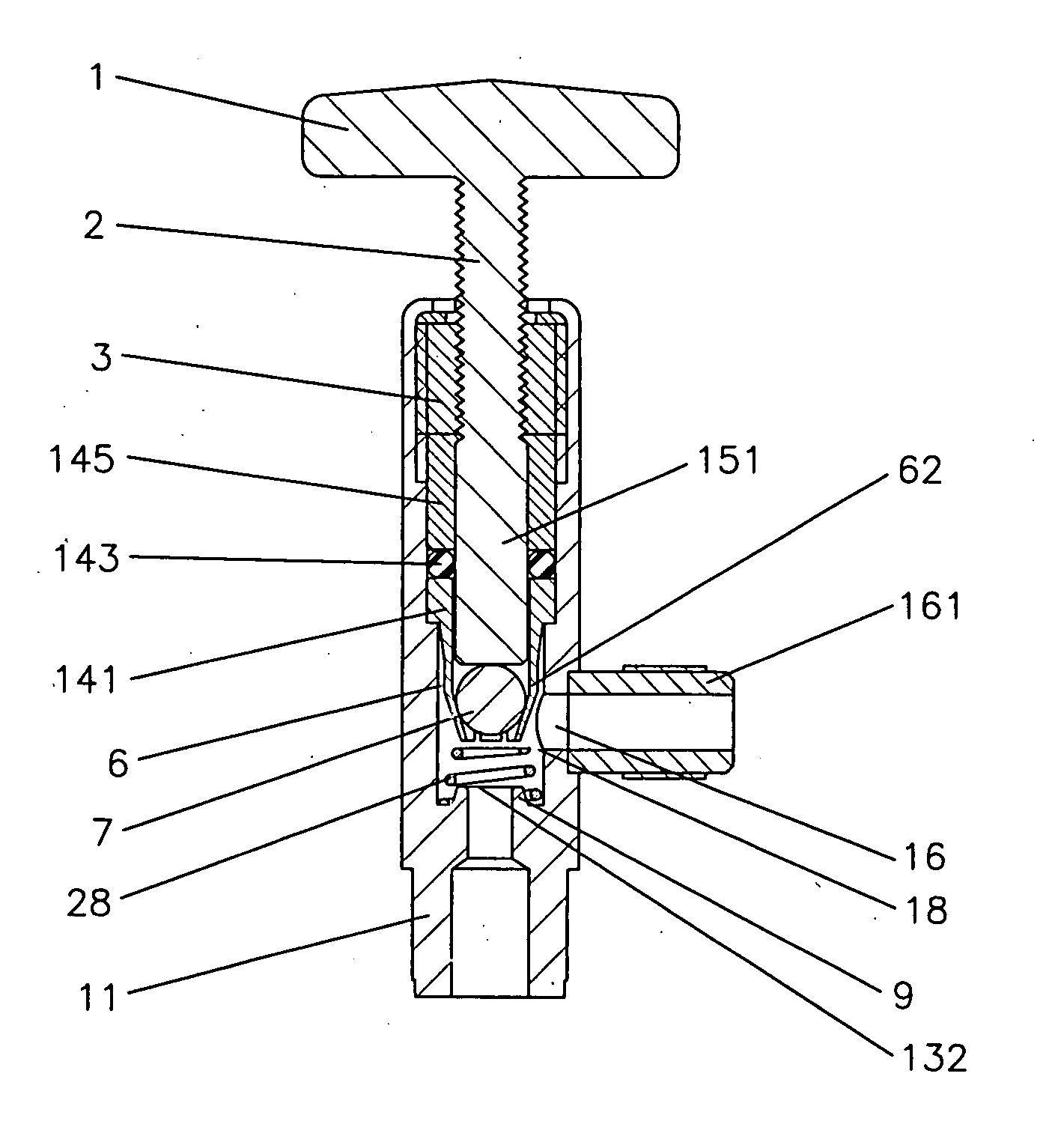

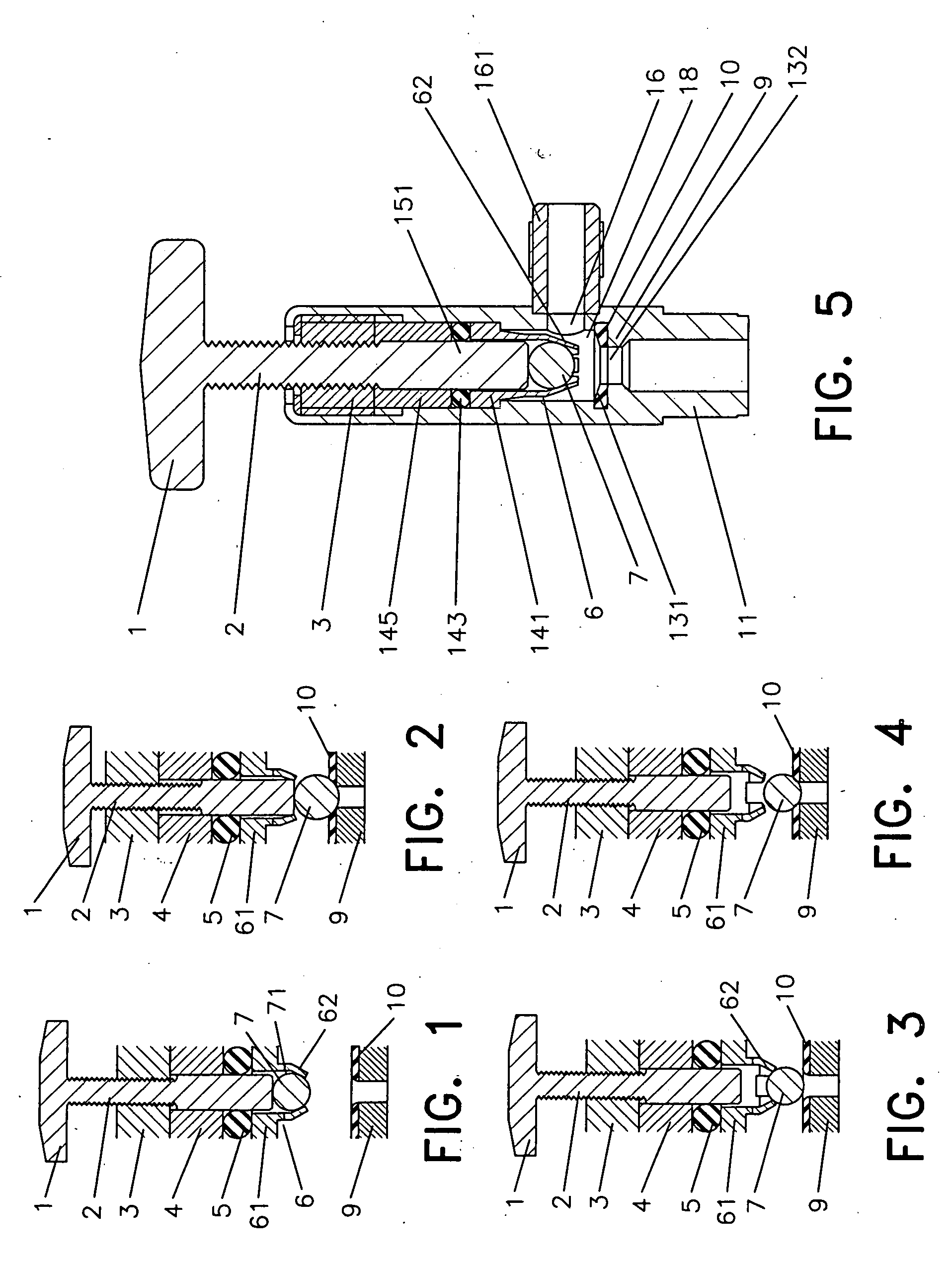

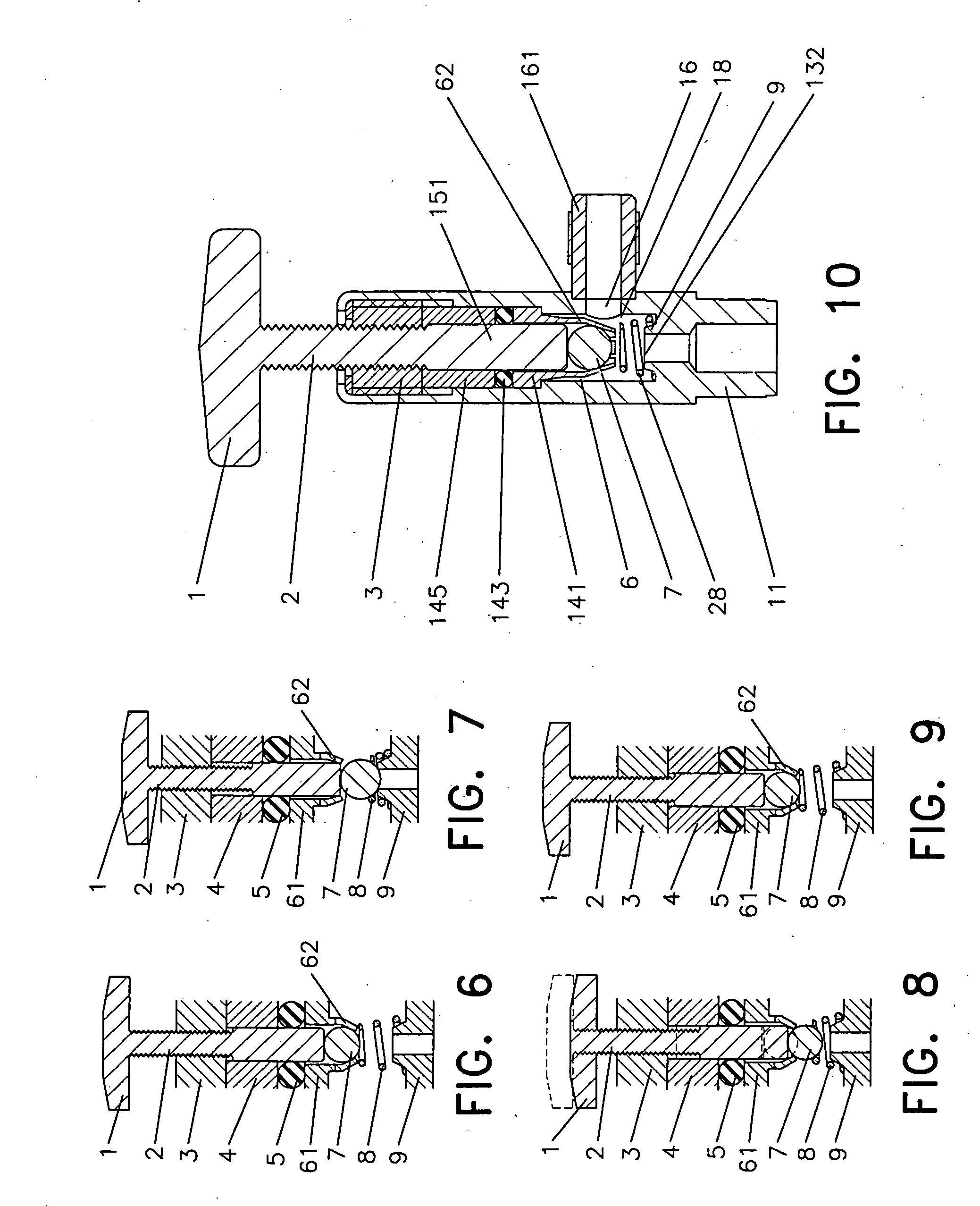

Spherical surface push-in sealing method and a sealing valve utilizing the method

InactiveUS20060284128A1Simple structureReliable constantOperating means/releasing devices for valvesLift valveEngineeringAxial force

The invention provides a spherical surface push-in sealing method using a valve core with a spherical surface to engage a seal base, wherein an initial position is arranged for the valve core, so that the valve core is retained in the initial position before use. When in use, the valve core is pushed out of the initial position by a forward axial force. The valve core moves axially in the valve chamber under the action of the axial forces to close and open the seal. The invention also provides a sealing valve using the sealing method comprising a valve body, a valve core, a seal base. The engaging surface of the valve core and the seal base being a spherical surface, wherein an elastic stand for the valve core is arranged in the valve body and opposite to the initial position for the valve core, a rod is arranged behind the valve core, and an opening is arranged on the valve chamber to communicate with the outside. The pre-tightening force of the seal surface of the invention can be regulated according to different needs. The seal is reliable and constant, and can be used for both the non-refillable sealing valve and the refillable sealing valve.

Owner:DONG YONGBIN

Thin film transistor substrate having structure for compensating for mask misalignment

A thin film transistors (TFTs) substrate is structured to maintain as constant across the area of the substrate a kickback voltage due to Miller capacitance between the drain and gate of each TFT even in the presence of manufacturing induced misalignments between the drain electrodes and corresponding gate lines. Each thin film transistor includes a gate electrode, an active layer formed on the gate electrode so as to overlap the gate electrode, first and second source electrodes respectively connected to first and second data lines each of which crosses the gate line while being insulated from the gate line, and an elongated drain electrode located between the first and second source electrodes and disposed over the gate electrode so as to a crossing length of the drain electrode is larger than an underlying width of the gate electrode such that misalignment induced shifts of the position of the gate electrode relative to the drain electrode does not substantially change overlap area between the two.

Owner:SAMSUNG DISPLAY CO LTD

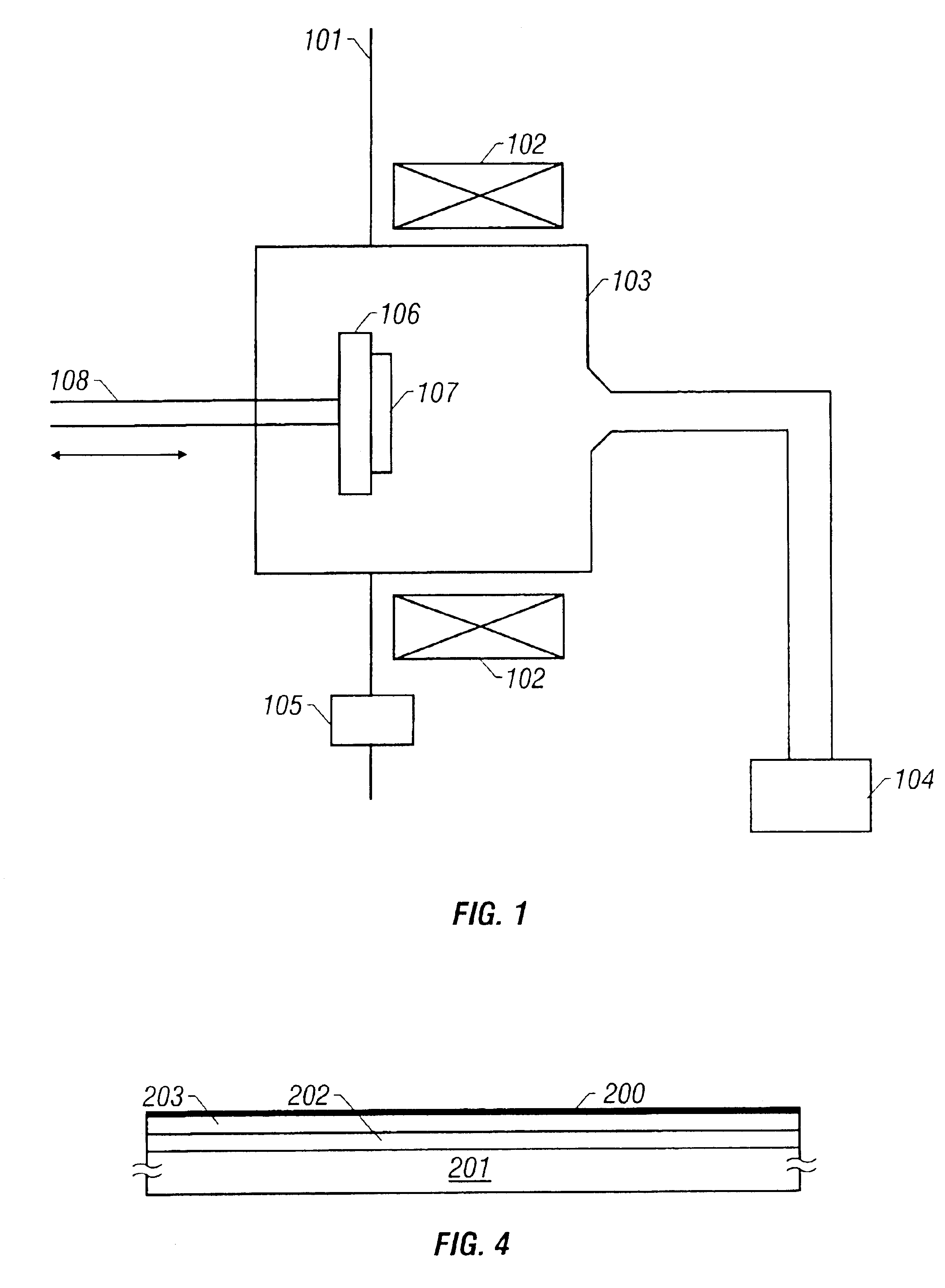

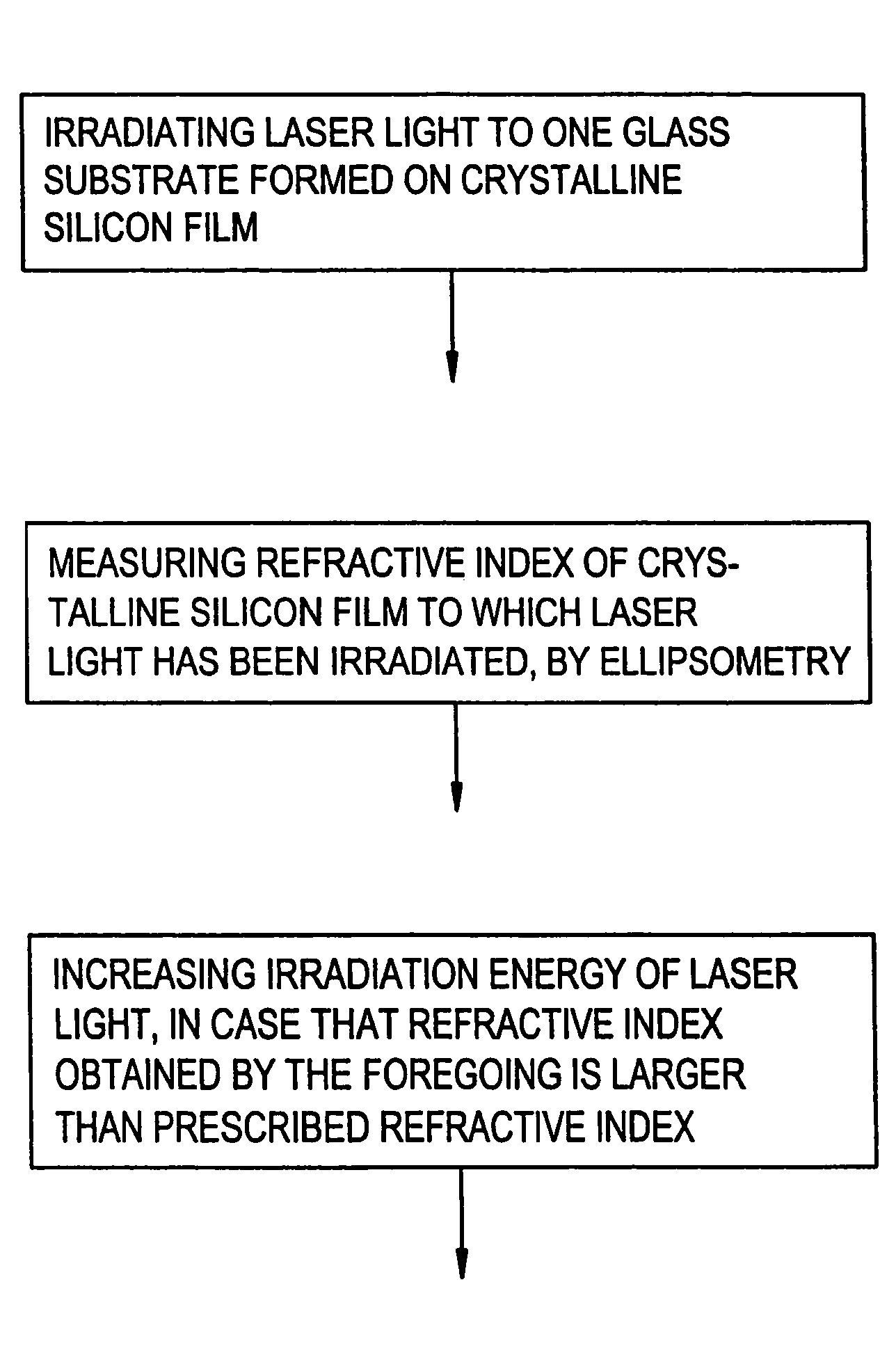

Optical processing apparatus and optical processing method

InactiveUS7078246B2Constant effectQuality improvementFrom gel statePolycrystalline material growthLaser lightOptical processing

In an annealing process in which laser light is irradiated to a semiconductor thin film, a refractive index of the semiconductor thin film after laser light irradiation is measured and conditions for the next laser light irradiation are adjusted based on the measured refractive index value. For example, laser light irradiation conditions are adjusted so that semiconductor thin films always have the same refractive index. As a result, the annealing can be performed under the same conditions at every laser light irradiation even if the laser light irradiation conditions vary unavoidably.

Owner:SEMICON ENERGY LAB CO LTD

Dielectric ceramic and laminated ceramic capacitor

ActiveUS8288301B2High dielectric constantReduce in quantityMaterial nanotechnologyFixed capacitor electrodesDielectricCeramic capacitor

A dielectric ceramic containing ABO3 in which A is Ba, possibly with at least one of Ca and Sr, and B is Ti, possibly with at least one of Zr and Hf as its main component, and Si as a accessory component. The dielectric ceramic includes main phase grains containing the ABO3 main component and secondary phase grains having a composition different from that of the main phase grains. The ratio of the Si content in the secondary phase grains to the total content of Si in the dielectric ceramic is 40% or more so that more Si is distributed in the secondary phase grains. It is preferable that the Si content in secondary phase grains be 30 mol % or more.

Owner:MURATA MFG CO LTD

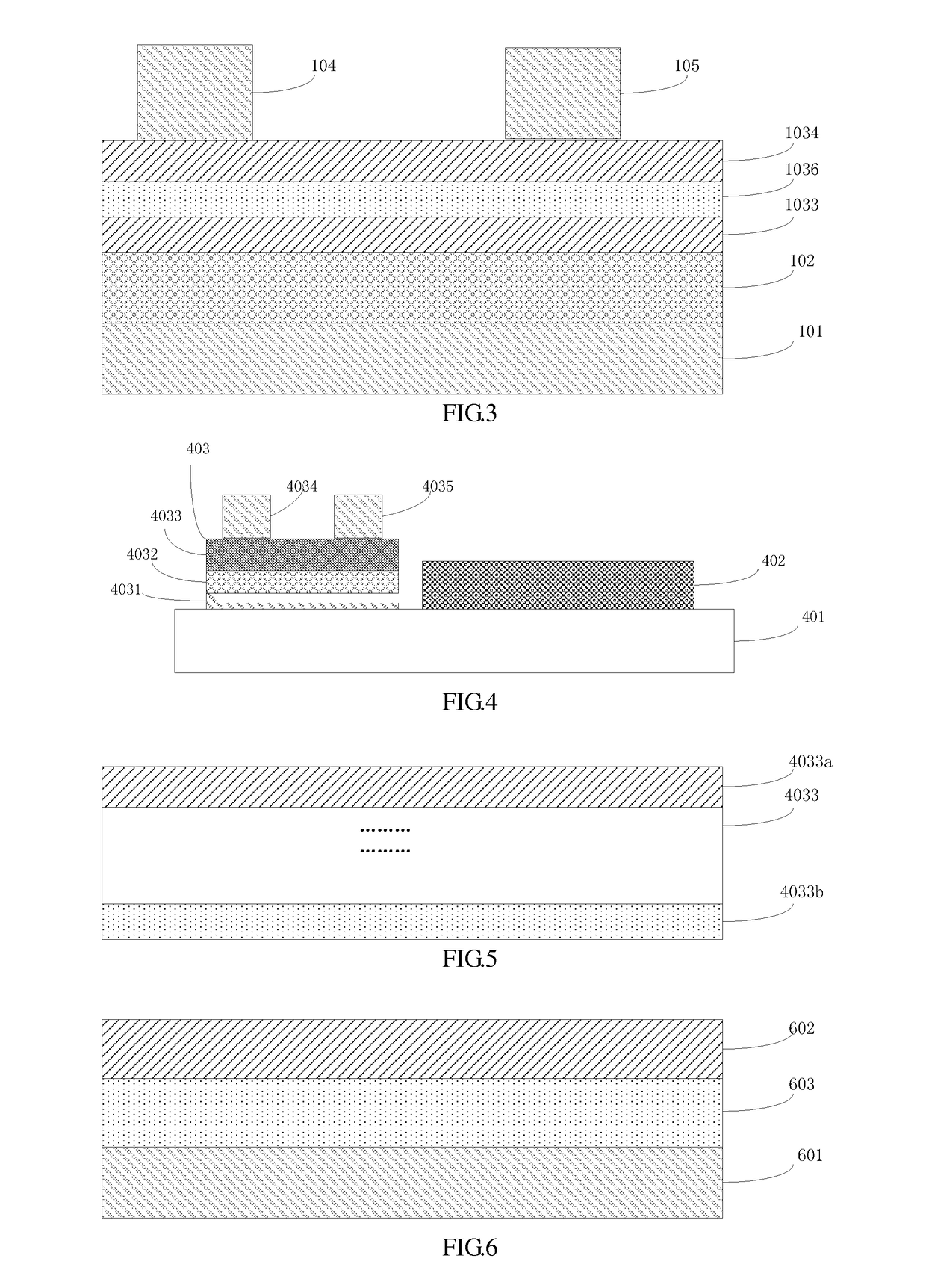

Thin film transistor, array substrate and liquid crystal display panel

ActiveUS20170133515A1Constant effectEnhancing the reliability of the thin film transistorTransistorSolid-state devicesOxide semiconductorLiquid-crystal display

A thin film transistor, an array substrate and a liquid crystal display panel are provided. The thin film transistor has an active layer which is formed from nitrogen-doped oxide semiconductor layers and a non-nitrogen doped oxide semiconductor layer. By disposing the non-nitrogen doped oxide semiconductor layer in the active layer of the nitrogen-doped thin film transistor, the mobility of the thin film transistor is kept constant for improving the reliability of the thin film transistor.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com