Anti-falling type automatic instrument

An instrument and anti-fall technology, applied in the field of instruments, can solve the problems of reduction of external impact force and weak practicability, and achieve the effect of protecting the internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

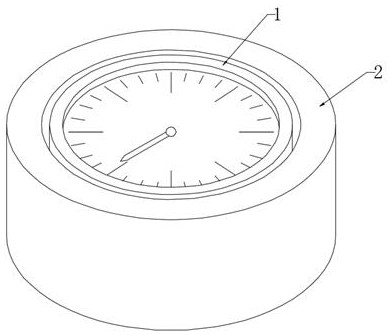

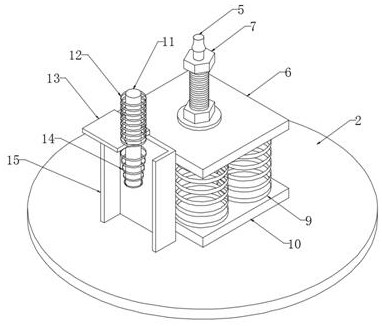

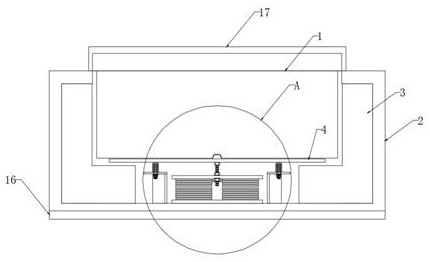

[0023] like Figure 1-2 As shown, including the instrument main body 1, the outer side of the instrument main body 1 is provided with a protective cover 2, the bottom of the instrument main body 1 is fixed with a limit plate 4, the middle part of the bottom end of the instrument main body 1 is provided with a nut groove, and the bottom of the limit plate 4 The middle part of the end is provided with two first lock nuts 7, the bottom of the first lock nut 7 is provided with the first connecting plate 6, the top middle part of the limit plate 4 is provided with the first screw hole, and the internal thread of the first screw hole A fastening bolt 5 is connected, the nut of the fastening bolt 5 is placed inside the nut groove, the middle part of the fastening bolt 5 passes through the first locking nut 7, and another first locking nut 7 is threaded The middle part of the bottom end of the first connecting plate 6 is provided with a nut groove, and the inside of the nut groove is ...

Embodiment 2

[0025] like Figure 1-4 As shown, both sides of the bottom of the limiting plate 4 are fixedly provided with metal connecting columns 11, and the top of the metal connecting columns 11 is provided with a second damping spring 12, and the bottom end of the second damping spring 12 is fixedly connected with a third Connecting plate 13, the bottom of metal connecting column 11 passes through the opening that the middle part of the top of the third connecting plate 13 offers, the middle part of the bottom end of the third connecting plate 13 is fixedly provided with the third damping spring 14, the bottom end of metal connecting column 11 Through the middle part of the third damping spring 14, and fixedly connected with the bottom end of the third damping spring 14, the bottom side of the third connecting plate 13 is fixedly connected with a U-shaped plate 15, through the second damping spring 12 and The elastic effect of the third shock-absorbing spring 14 cuts the external impac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com