A hot stamping system with an automatic hot stamping quality detection device

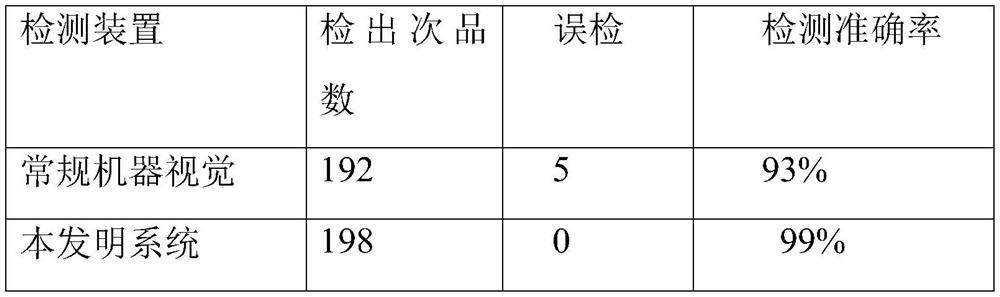

A detection device and quality technology, applied in transfer printing, general parts of printing machinery, printing, etc., can solve the problems of inability to identify image differences, prone to false detection, prone to reflection, etc., to avoid segmentation requirements and improve detection. Accuracy and the effect of avoiding false detections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

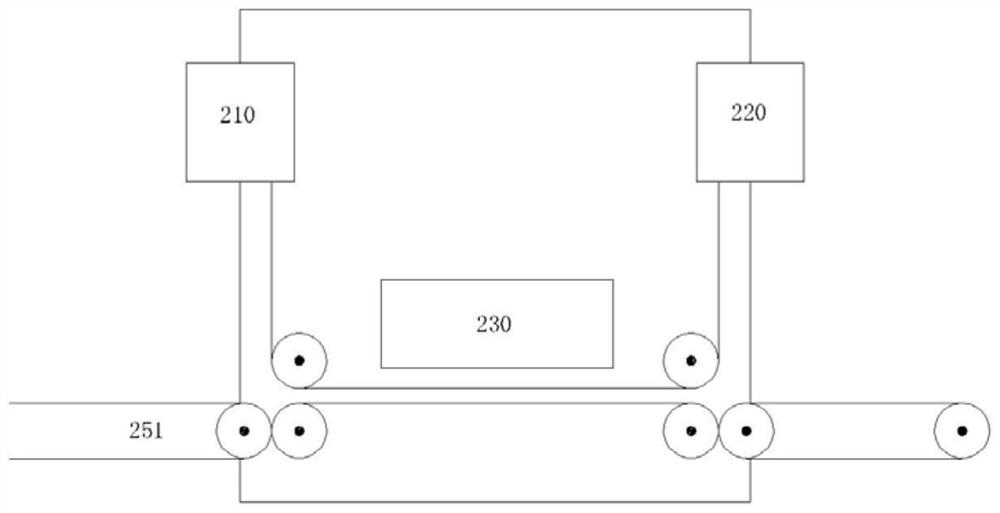

[0022] In the following, description will be mainly focused on the hot stamping quality detection device provided downstream of the imprint transfer device.

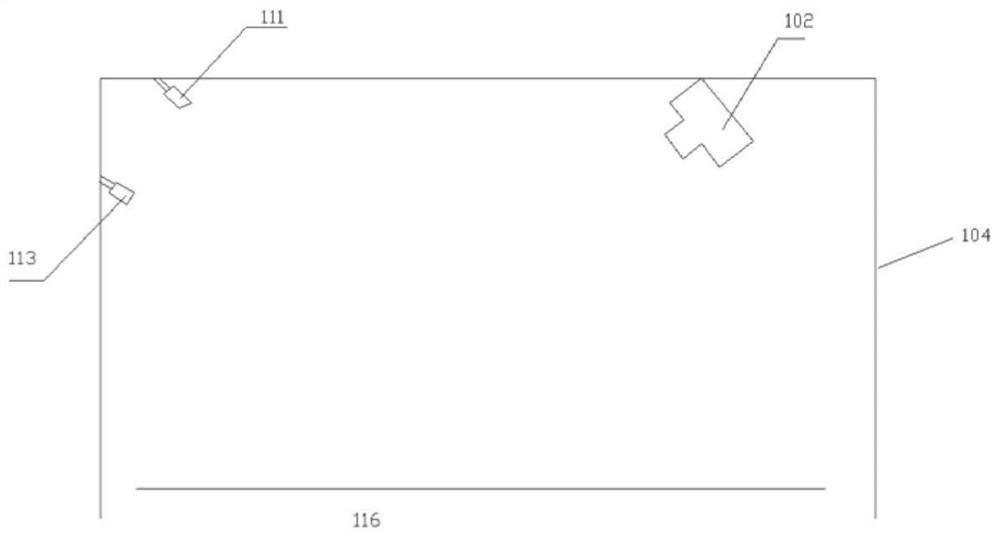

[0023] The automatic hot stamping quality detection device in this embodiment includes a light source, an image acquisition device 102 , an image processing device, and a detection box 104 . The detection box 104 is an opaque box body, which is covered above the conveyor belt 116. The front and rear ends of the box body are respectively provided with horizontal openings that allow the conveyor belt and the hot stamping products on it to pass through—the inlet port and the outlet port (not shown in the figure). drawing), preferably, a shading plate or a shading curtain is added inside the inlet and outlet to avoid or reduce the entry of external light sources into the detection box 104 as much as possible. The hot-stamped product enters the inspection box through the inlet port. The conveying direction of the conveyor be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com