Cloth dip dyeing device for garment production

A cloth and clothing technology, which is applied in the field of cloth dip-dyeing devices for clothing production, can solve the problems of cloth wrinkling and uneven color, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

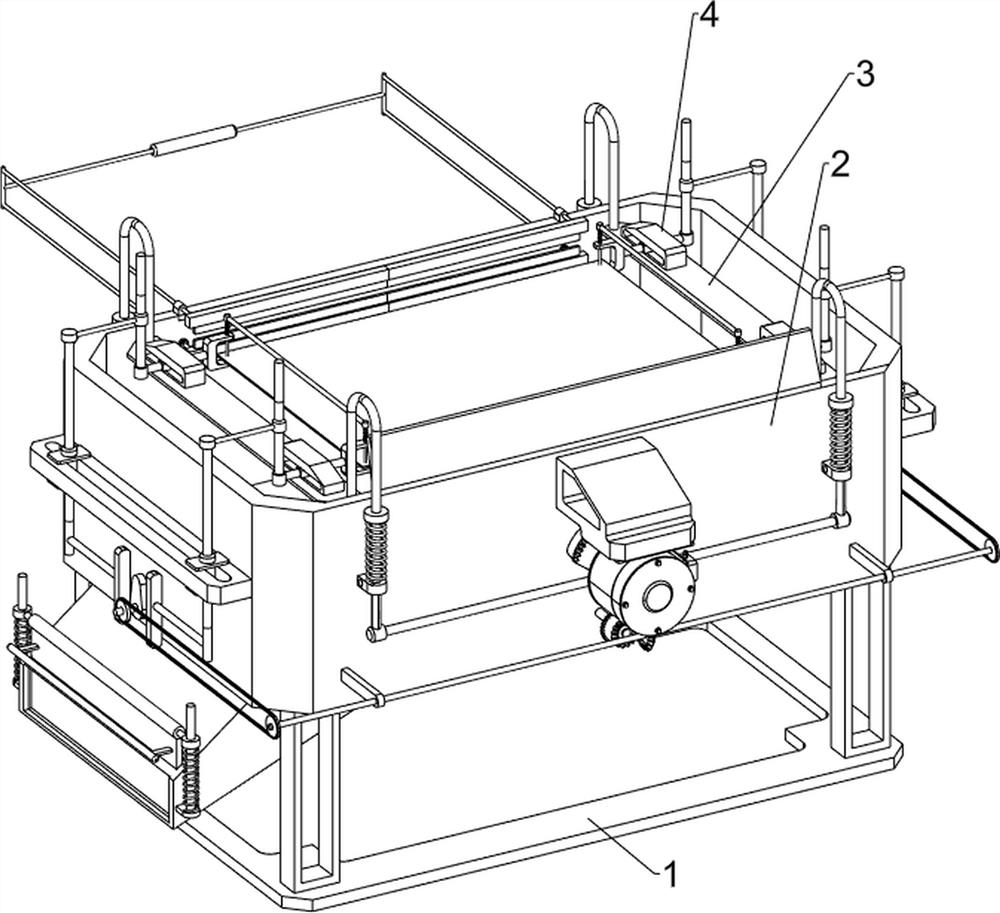

[0022] Such as Figure 1-3 As shown, a cloth dipping device for garment production includes a base 1, a dipping pool 2, a vertical shaking mechanism 3 and a horizontal shaking mechanism 4, a dipping pool 2 is arranged on the top of the base 1, and the front and rear side walls of the dipping pool 2 A vertical shaking mechanism 3 is provided, and a horizontal shaking mechanism 4 is arranged on the dipping pool 2 .

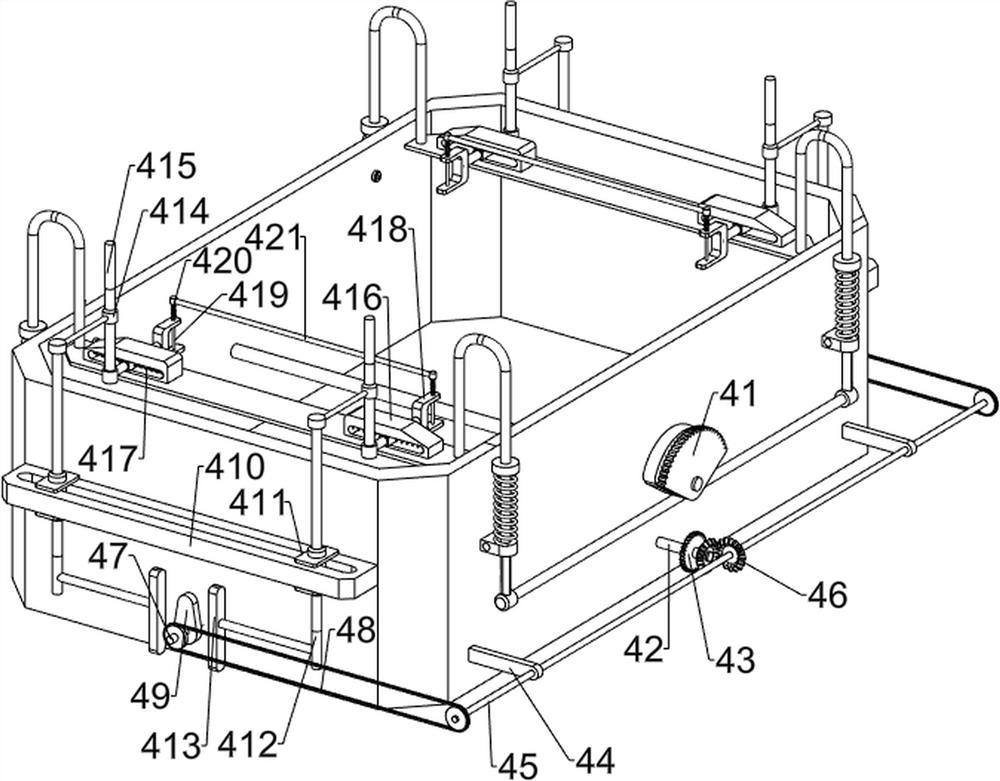

[0023] The vertical shaking mechanism 3 includes a first sliding sleeve 31, an n-shaped sliding rod 32, a round block 33, a first elastic member 34, a first fixed rod 35, a first fixed plate 36, a first rotating shaft 37, and a first cam 38 , the fixed seat 39 and the motor 310, the two side walls before and after the dipping pool 2 are symmetrically arranged with the first sliding sleeve 31, the first sliding sleeve 31 is slidably provided with an n-shaped slide bar 32, and the upper side of the n-shaped slide bar 32 A round block 33 is provided, a first elastic m...

Embodiment 2

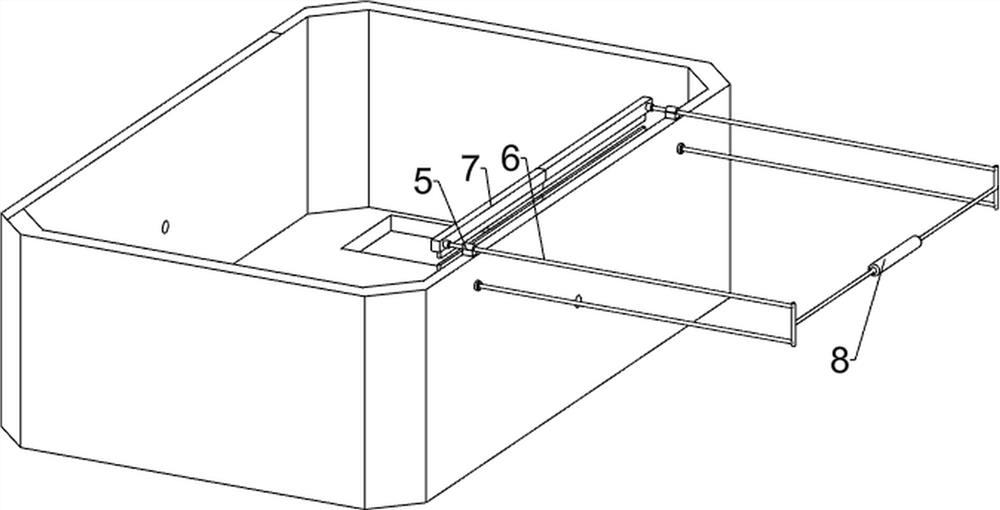

[0027] Such as Figure 4-5 As shown, on the basis of Embodiment 1, it also includes a second sliding sleeve 5, a sliding frame 6, a scraper 7 and a handle 8, and a second sliding sleeve 5 is symmetrically arranged on the rear side of the top of the dipping pool 2. 2 is placed with a sliding frame 6, the rear side wall of the dipping tank 2 is located below the second sliding sleeve 5 and has a second round hole, the sliding frame 6 is slidingly matched with the second sliding sleeve 5 and the second round hole, and the top of the sliding frame 6 A scraper 7 is arranged on the front side, and a handle 8 is arranged on the rear side of the top of the sliding frame 6 .

[0028] In the cloth dip-dyeing operation, small particles are prone to agglomeration after the dye is used for a long time, which affects the cloth dip-dyeing quality. The staff holds the handle 8 to push the sliding frame 6 to move in the second sliding sleeve 5 and the second round hole to drive the scraper 7 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com