Concrete distributing mechanism for concrete pump

A concrete pump and concrete technology, which is applied in the direction of building structure, building material processing, construction, etc., can solve the problems of physical consumption, high labor intensity of personnel, easy contamination of concrete, etc., and achieve the effect of saving energy and manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

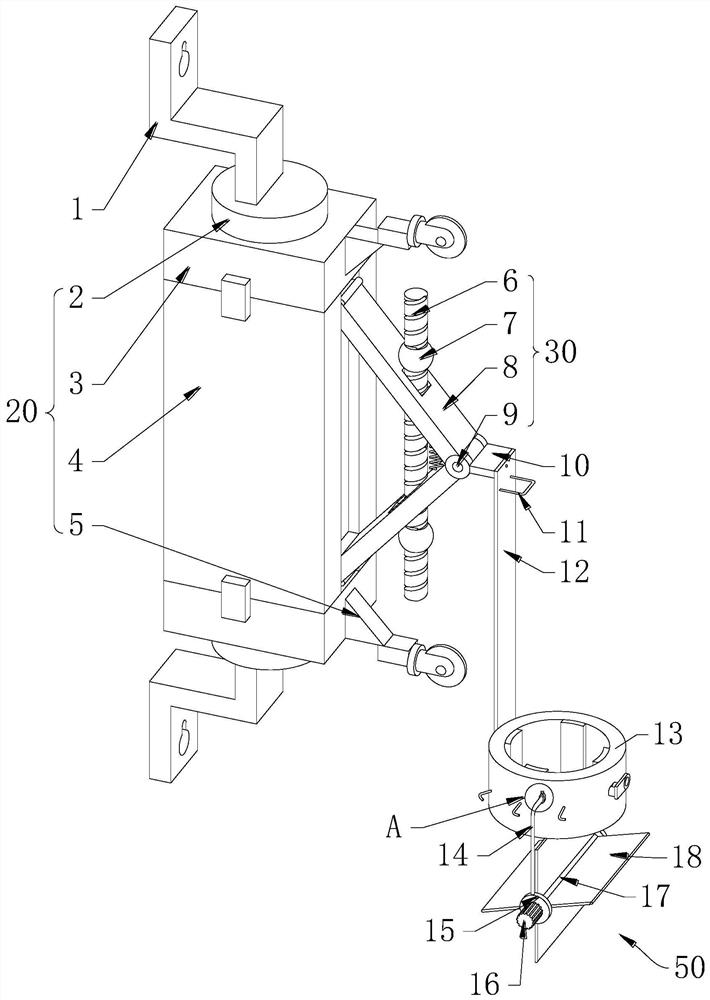

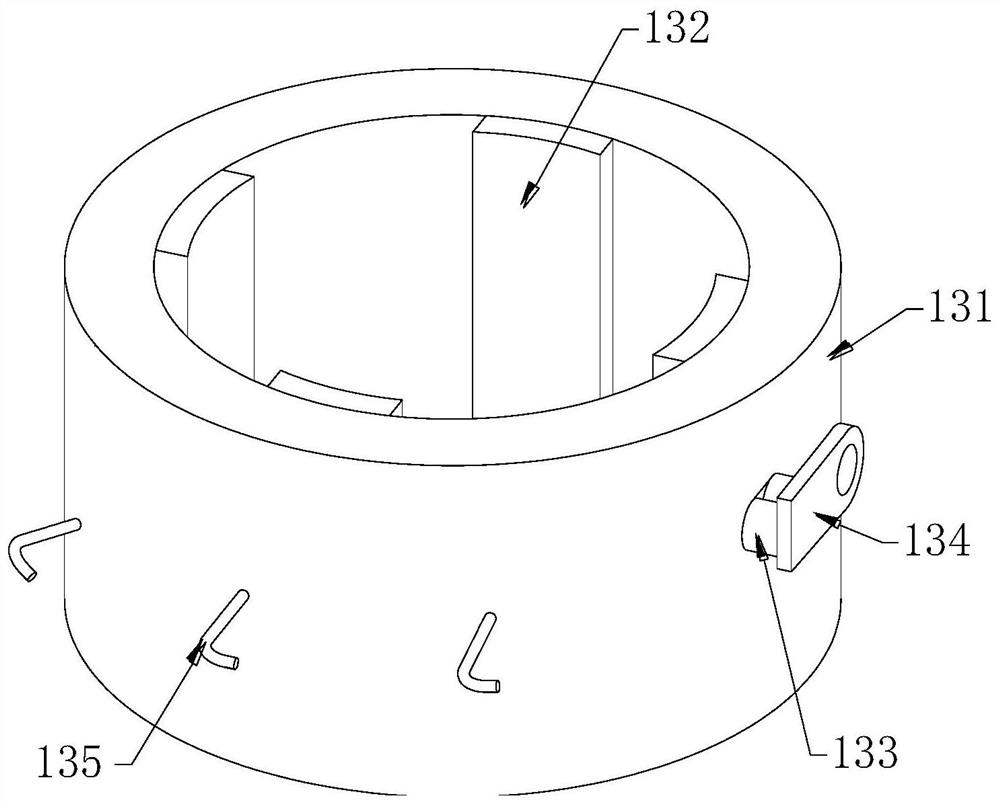

[0024] First example: see Figure 1-Figure 3 , a concrete distributing mechanism for concrete pumps, including a support assembly 20, the upper and lower ends of the support assembly 20 are fixed to the hanging board 1 for hanging on the wall, and the inside of the two hanging boards 1 are provided with gourd holes with a narrow top and a wide bottom , the right end of the support assembly 20 is installed with a length adjustment part 30, and the right end of the length adjustment part 30 is installed with a vertical plate 12, and the lower end of the vertical plate 12 is fixed with a pipe clip 13 for clamping and fixing the discharge pipe of the concrete pump. L-shaped rods 14 are fixed at both ends, and a pusher 50 for pushing concrete is installed at the lower ends of the two L-shaped rods 14 .

[0025] Nails are nailed into the corresponding position on the wall, and then hung on the nails through the gourd holes on the two hanging boards 1, so that the mechanism can be hu...

no. 2 example

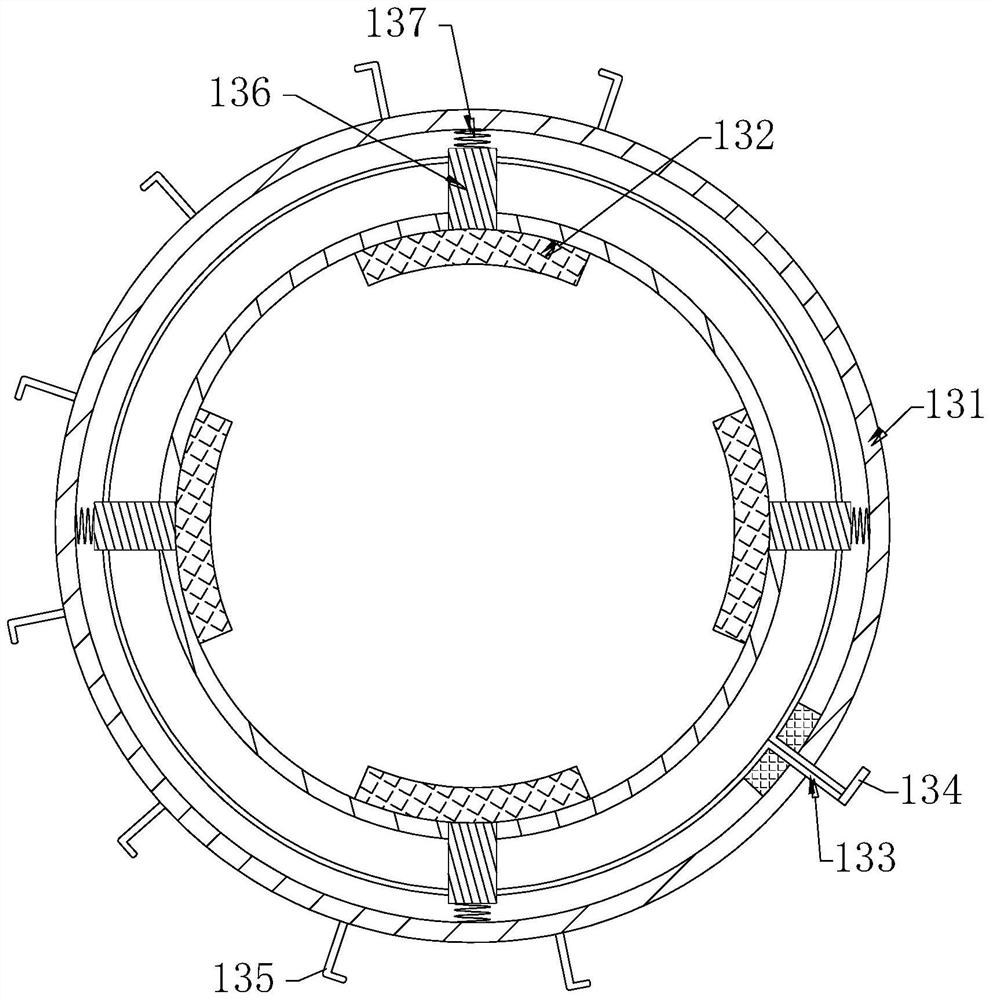

[0031] Second example: see Figure 1-Figure 4 , the annular outer end of the annular housing 131 fixes the ring 141, the L-shaped rod 14 is arranged inside the ring 141 and extends from the ring 141, the upper end of the ring 141 is threaded to install a locking bolt 142, and the locking bolt 142 passes through The upper end of the ring 141 is closely connected with the upper end of the L-shaped rod 14, and the L-shaped rod 14 is locked by the locking bolt 142, so that the pusher 50 is set at the discharge port of the concrete pump discharge pipe, and the pusher 50 needs to be adjusted. position, the locking bolt 142 can be loosened to unlock the L-shaped rod 14, and then the L-shaped rod 14 can be rotated to drive the pusher 50 to rotate until the pusher 50 is moved from the discharge port of the concrete pump discharge pipe. Tighten the locking bolt 142 after leaving, so that the pusher 50 is removed from the discharge port of the concrete pump discharge pipe when the pusher...

Embodiment 1

[0038] Embodiment 1 realizes wall-mounted distribution, which is convenient for concrete distribution on the ground. Embodiment 2 realizes mobile distribution, which is convenient for concrete distribution on the wall, which is suitable for different use scenarios and has good use effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com