Control valve

A control valve and valve body technology, applied in valve details, valve device, valve operation/release device, etc., can solve problems affecting the valve opening performance of control valves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

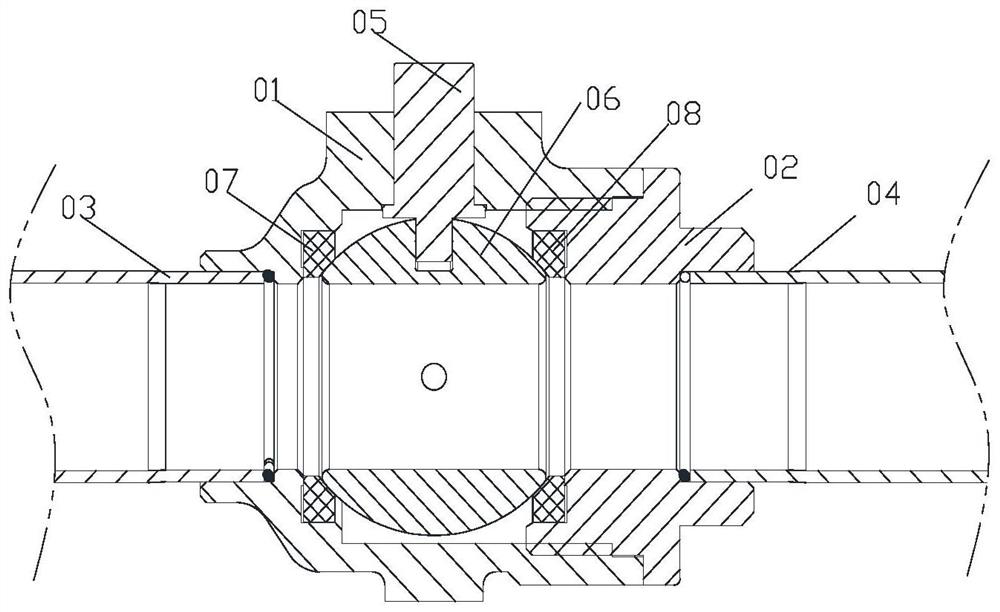

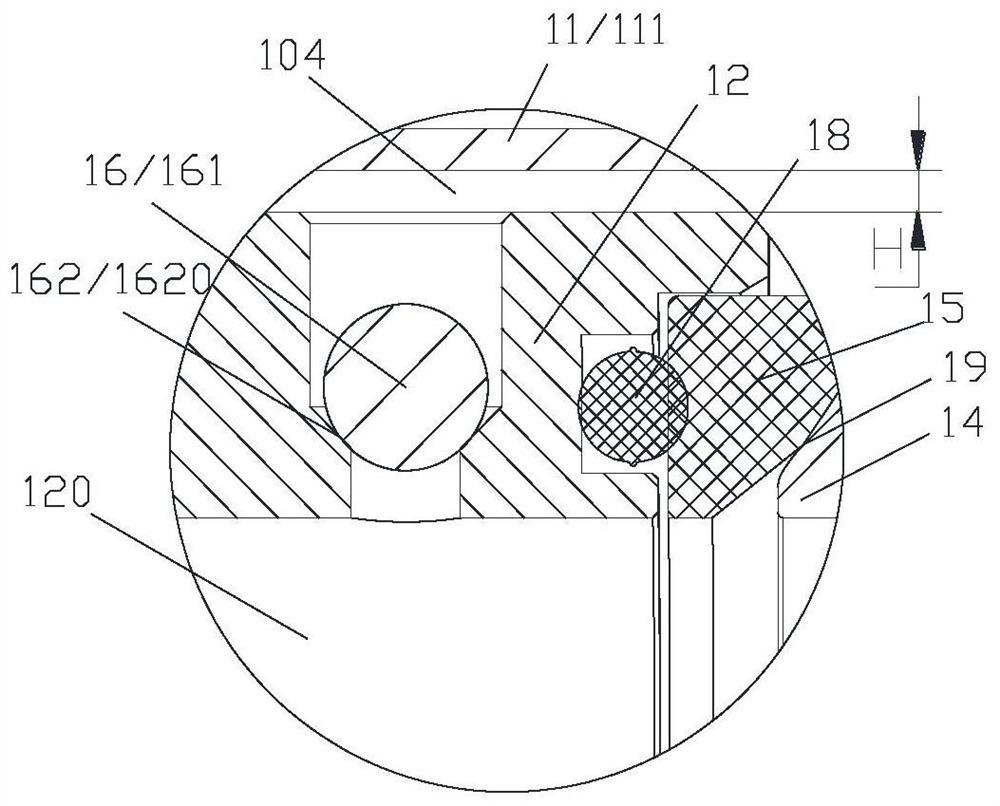

[0030] The core of the present invention is to provide a control valve. By setting the first one-way fluid control component on the first valve seat, the pressure of the fluid on both sides of the first sealing gasket tends to be balanced in the closed state, reducing the pressure of the first sealing gasket. The force of the pad on the valve core reduces the torque required for the valve stem to drive the valve core to rotate when the valve is opened, thereby improving the valve opening performance of the control valve.

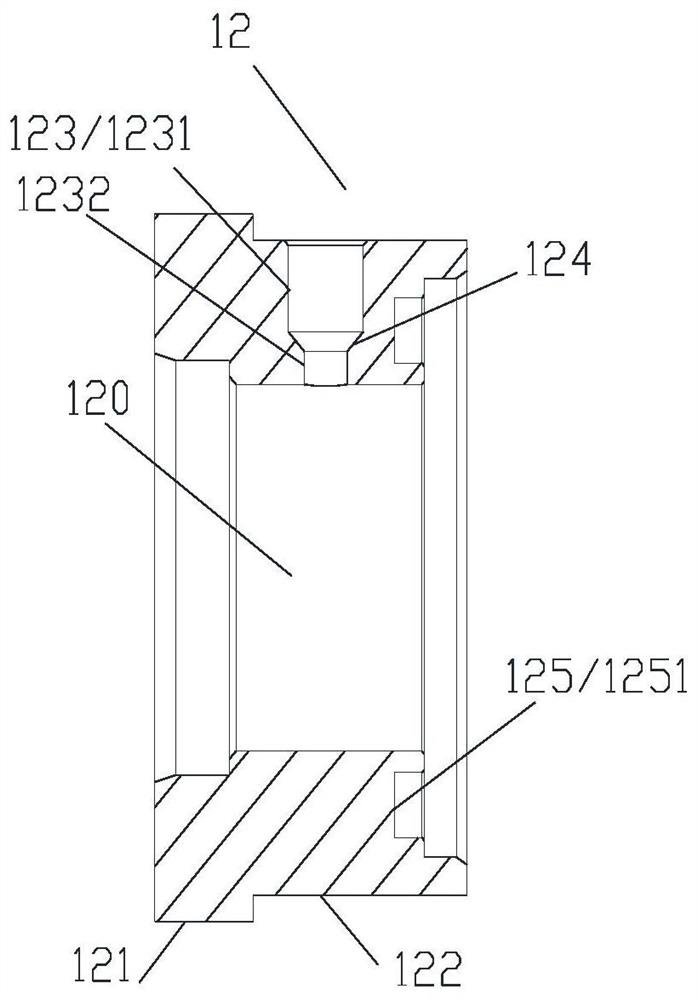

[0031] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0032] What needs to be explained here is that the upper and lower localizers involved in this article are based on Figure 2 to Figure 5 The components are located in the drawings and the positions of the compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com