Reciprocating compressor with linear motor

A linear motor and compressor technology, applied in the field of reciprocating compressors, can solve problems such as yield loss, reduction of compressor volumetric yield, and harmful gas discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

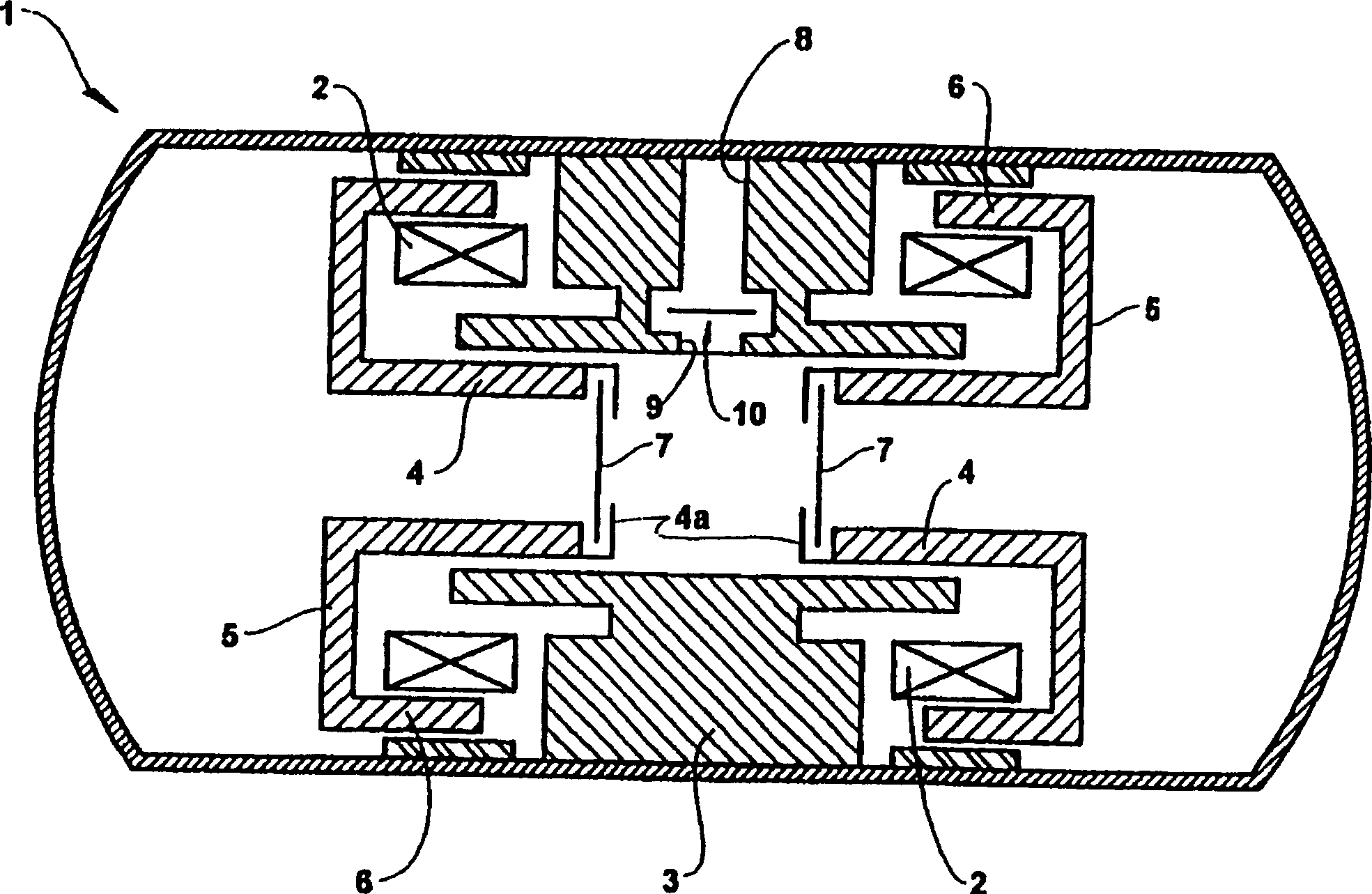

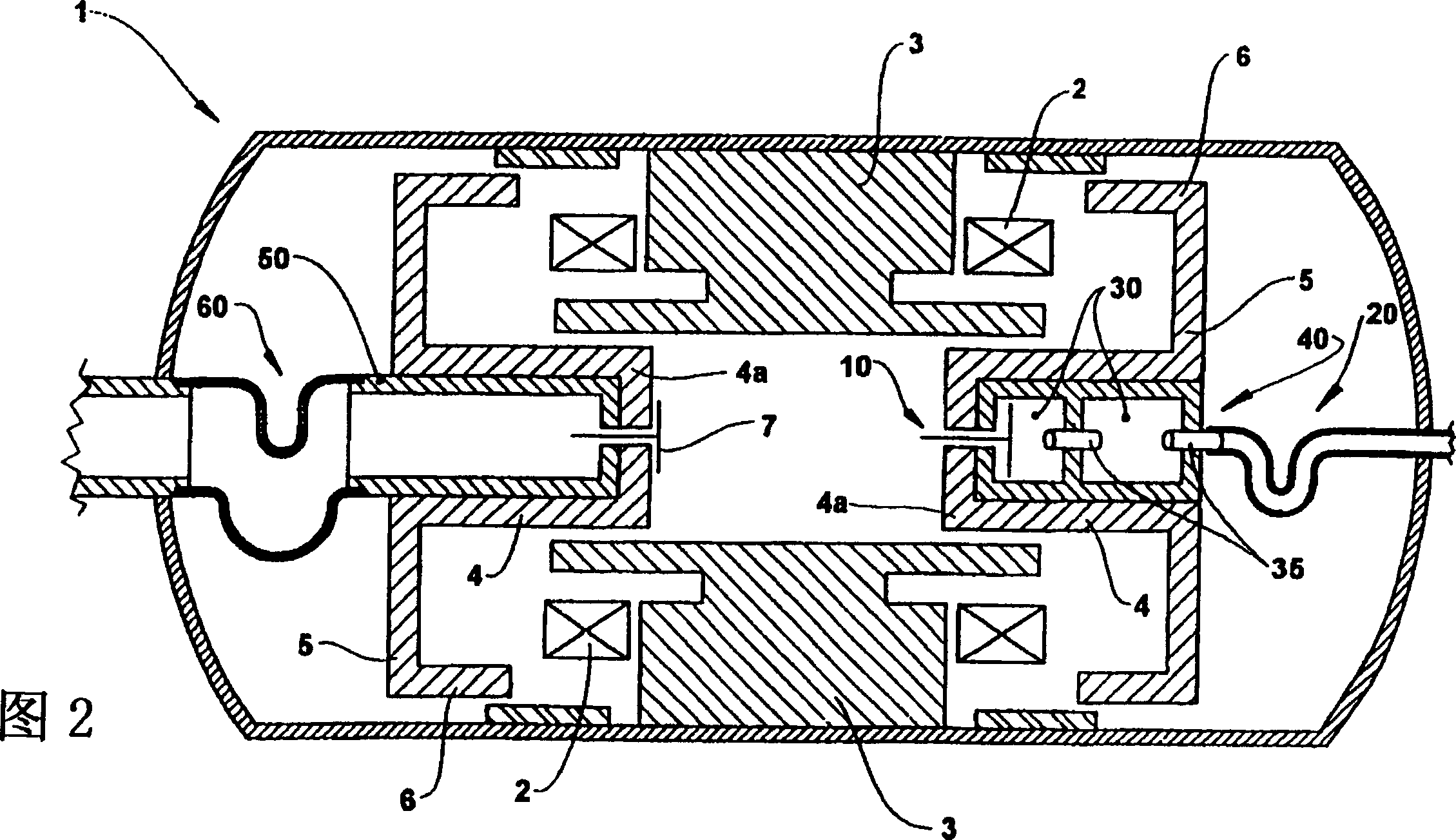

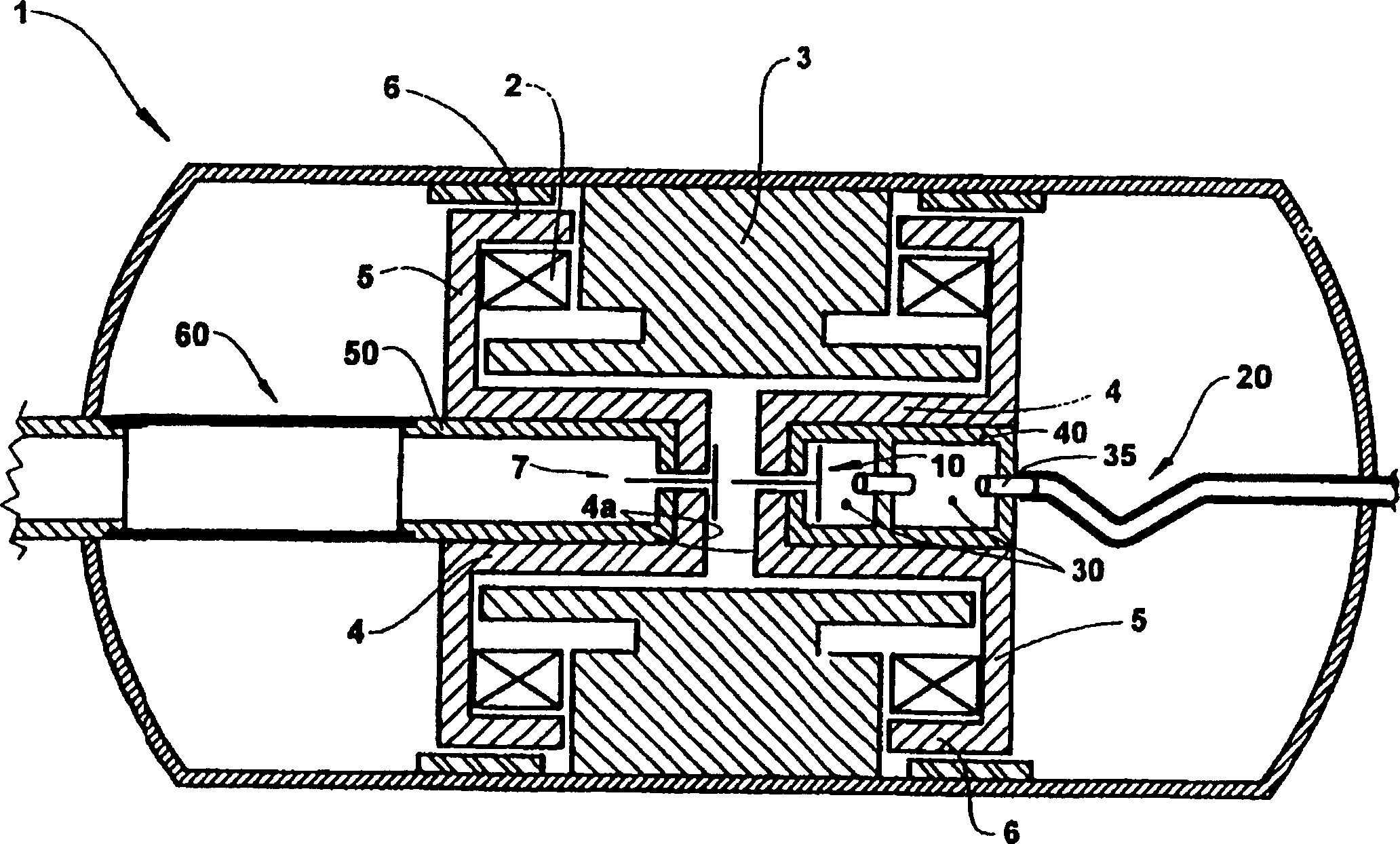

[0016] The invention is described for a reciprocating compressor driven by a linear motor applied to a refrigeration system, which is housed in an airtight casing 1 having a discharge duct (not shown) which makes the compressor Connected to, for example, a refrigeration system, the above-mentioned linear motor comprises motor parts 2 axially aligned with each other, usually fixed outside the cylinder 3 .

[0017] In this construction, the compressor has a pair of pistons 4, generally tubular, housed within a cylinder 3 and axially aligned with each other so as to be capable of relative axial movement towards and away from each other. Each of the above-mentioned pistons 4 is respectively connected to a corresponding driving device 5, generally tubular, located outside the cylinder 3, with a magnet 6, which is driven in the axial direction when the corresponding motor part 2 is energized. This separating and approaching movement of the piston 4 within the cylinder 3 determines t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com