Winding device for polyester yarn production

A winding device and technology of polyester yarn, applied in the field of polyester yarn production, can solve problems such as breaking and uneven shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

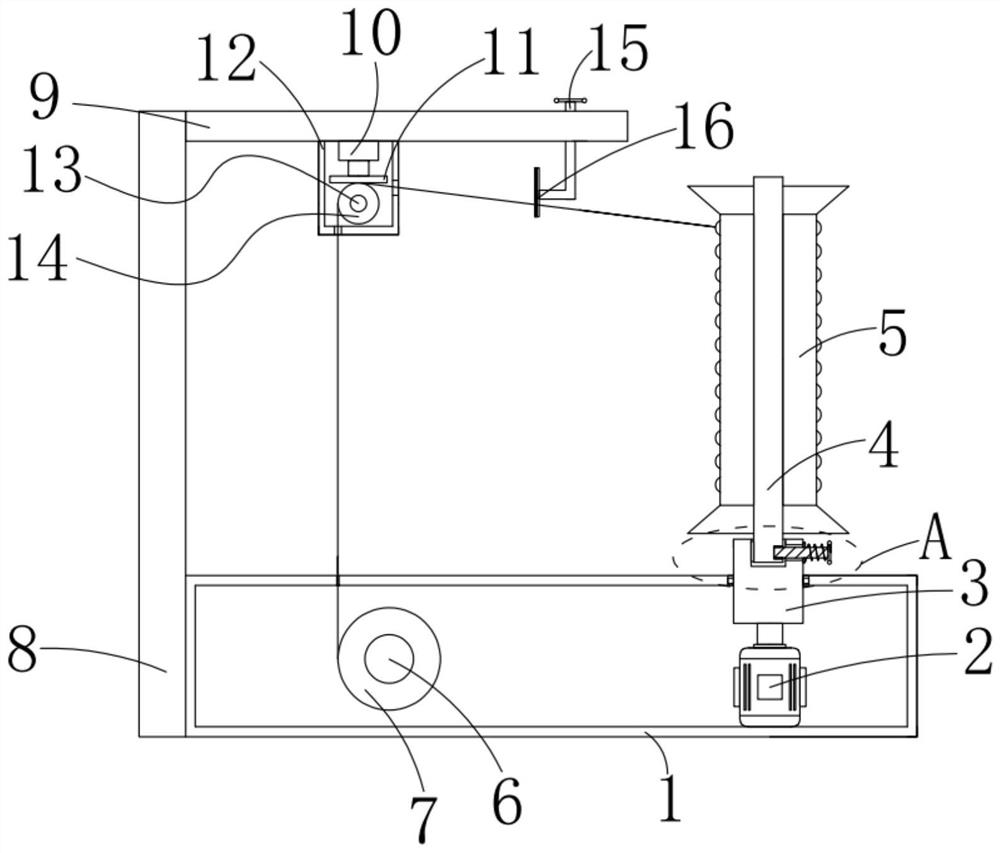

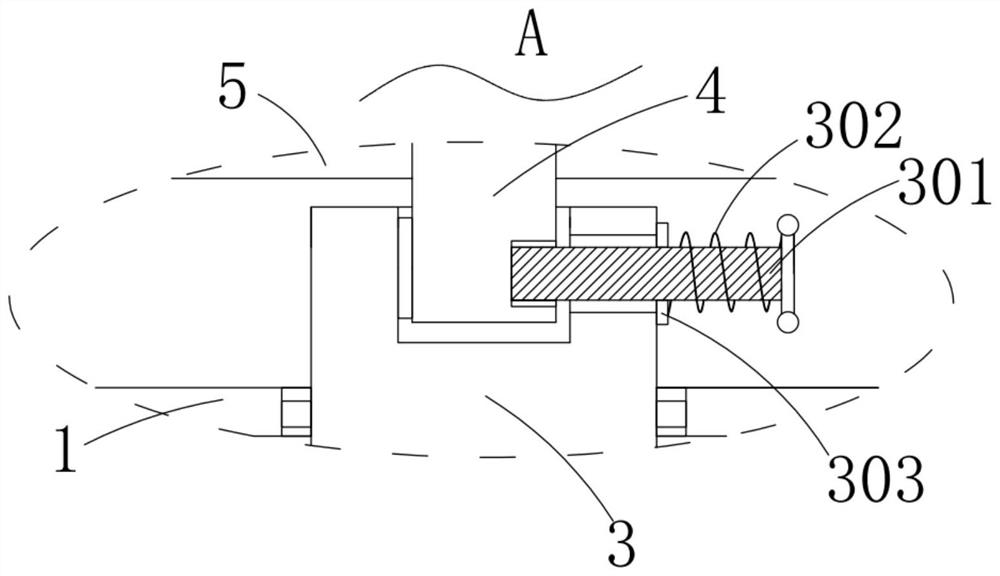

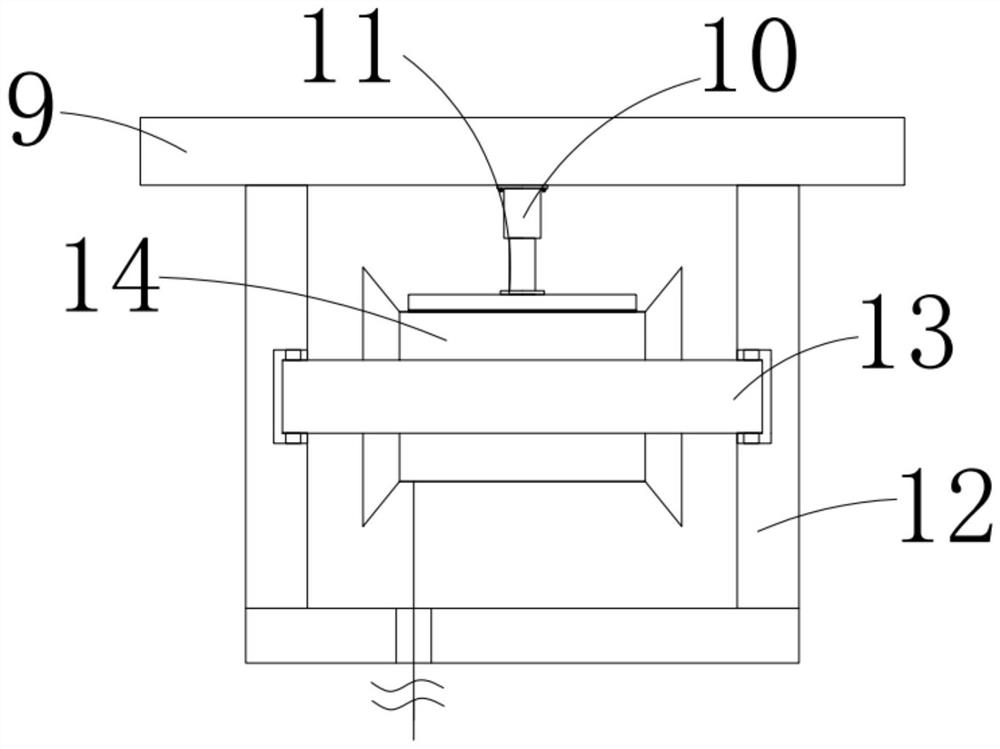

[0023] Please refer to figure 1 , figure 2 , image 3 with Figure 4 ,in, figure 1 A schematic diagram of a formal sectional structure of a preferred embodiment of a winding device for polyester yarn production provided by the present invention; figure 2 for figure 1 Schematic diagram of the enlarged structure in part A; image 3 It is an assembly drawing of the first horizontal plate, extrusion block, fixed box, second rotating rod and guide wheel in the present invention; Figure 4 for figure 1 Schematic plan view of the structure of the first transverse plate, L-shaped moving rod, round rod and second compression spring. The winding device used for polyester yarn production comprises: installation box 1; drive motor 2, said drive motor 2 is fixedly installed on the bottom inner wall of installation box 1; On the output shaft, the top of the rotating block 3 extends to the top of the installation box 1; the rotating rod 4, the rotating rod 4 is fixedly installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com