Multidirectional rotary connecting structure based on machinery

A technology of rotary connection and connection structure, applied in the direction of connection components, mechanical equipment, pivot connections, etc., can solve problems such as poor convenience, insufficient fastness of clamp connection bolts and nuts, and inability to achieve joint locking and anti-loosening of multiple locking structures. , to achieve the effect of improving the fixing effect and improving the convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

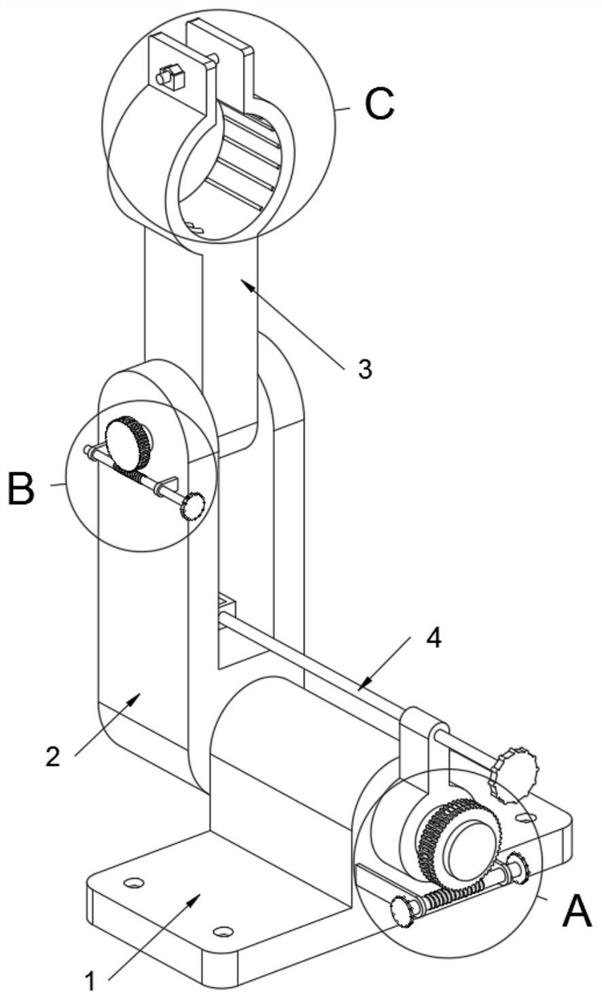

[0034] as attached figure 1 to attach Figure 8 Shown:

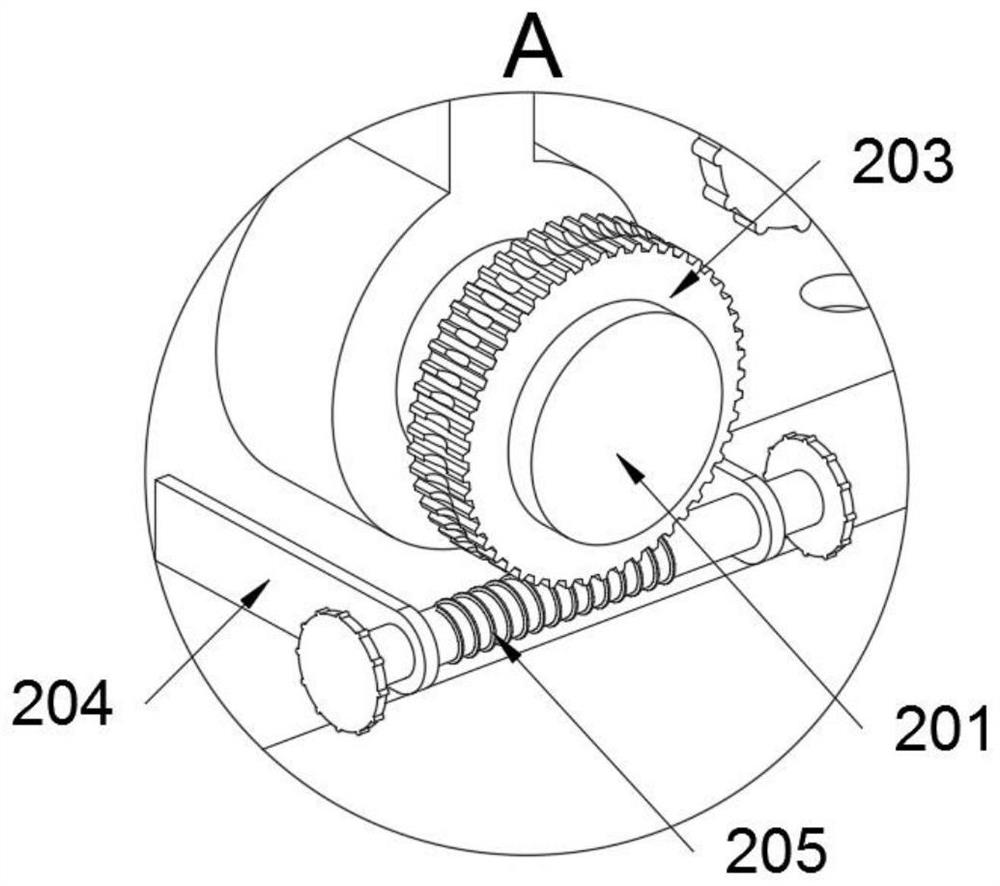

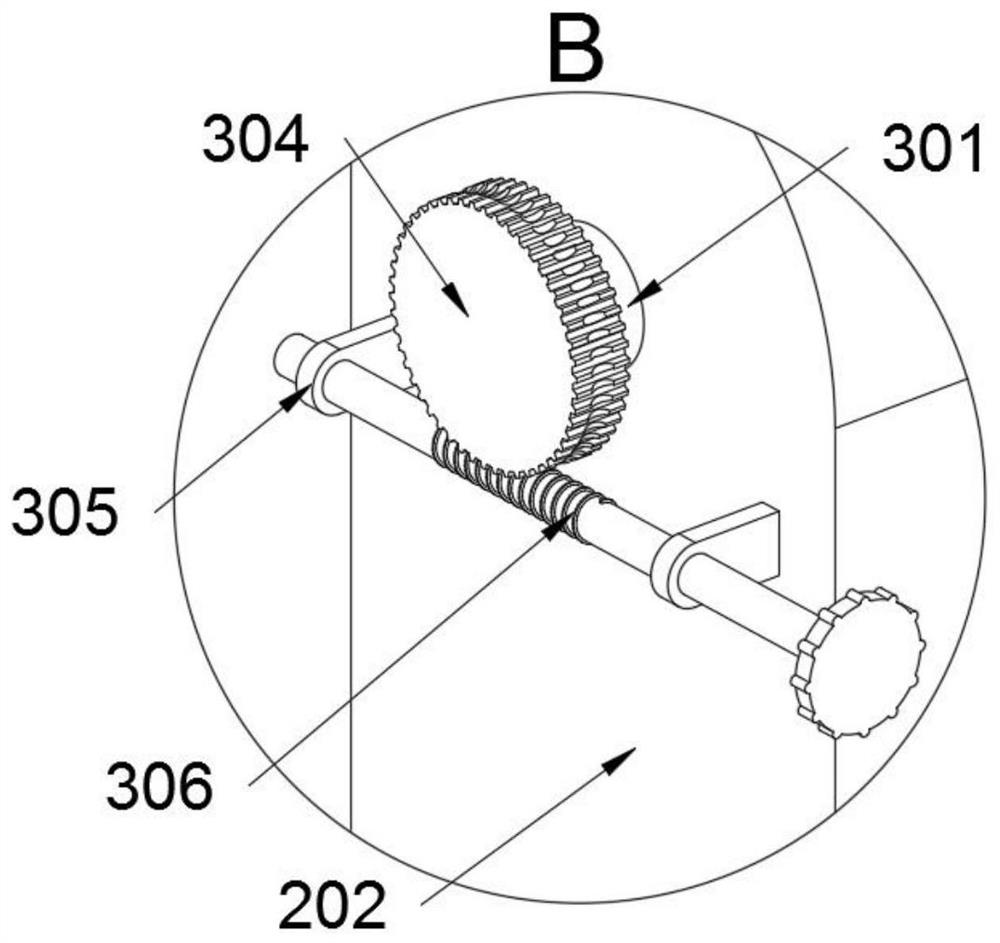

[0035]The present invention provides a multi-directional rotating connection structure based on machinery, including a base 1; a connecting arm structure 2 is connected to the base 1, and a connecting structure 3 is connected to the connecting arm structure 2, and an auxiliary structure 2 is connected to the connecting arm structure 2; Structure 4; refer to eg Figure 5 with Figure 7 , the connection structure 3 includes a nut seat 307 and a nut 308, the nut seat 307 is welded on the clamp 303, and a nut 308 is placed in the nut seat 307, and when the nut 308 is placed in the nut seat 307, the nut 308 is in a position-limiting state , thus improving the convenience when the clamp 303 bolt is locked; refer to as Figure 5 with Figure 7 , the connection structure 3 also includes a fixing hole B30303, and the clamp 303 is provided with a fixing hole B30303; when the nut 308 is placed in the nut seat 307, the threaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com