A remote monitoring and multi-channel self-regulating desuperheating system

A remote monitoring and self-regulating technology, applied in superheating temperature control, steam superheating, lighting and heating equipment, etc., can solve problems such as overlapping, small desuperheating water flow, and inability to make smooth transitions, so as to achieve broad application prospects and reduce use costs , the effect of stabilizing the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0034] 实施例:

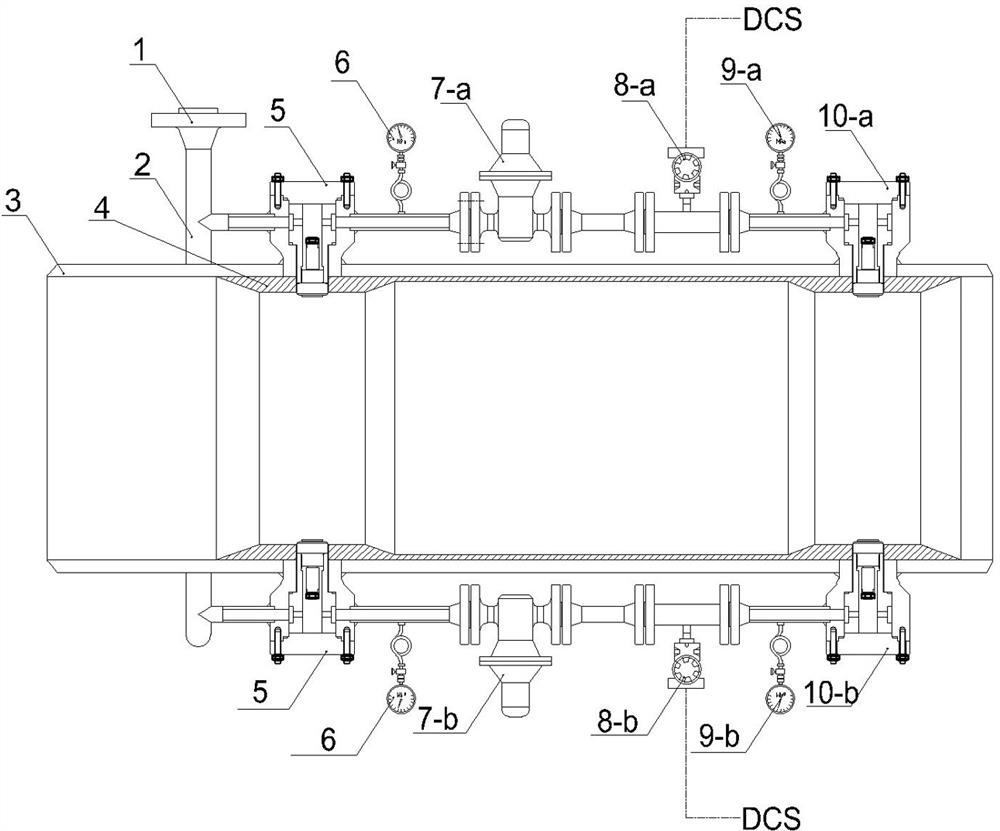

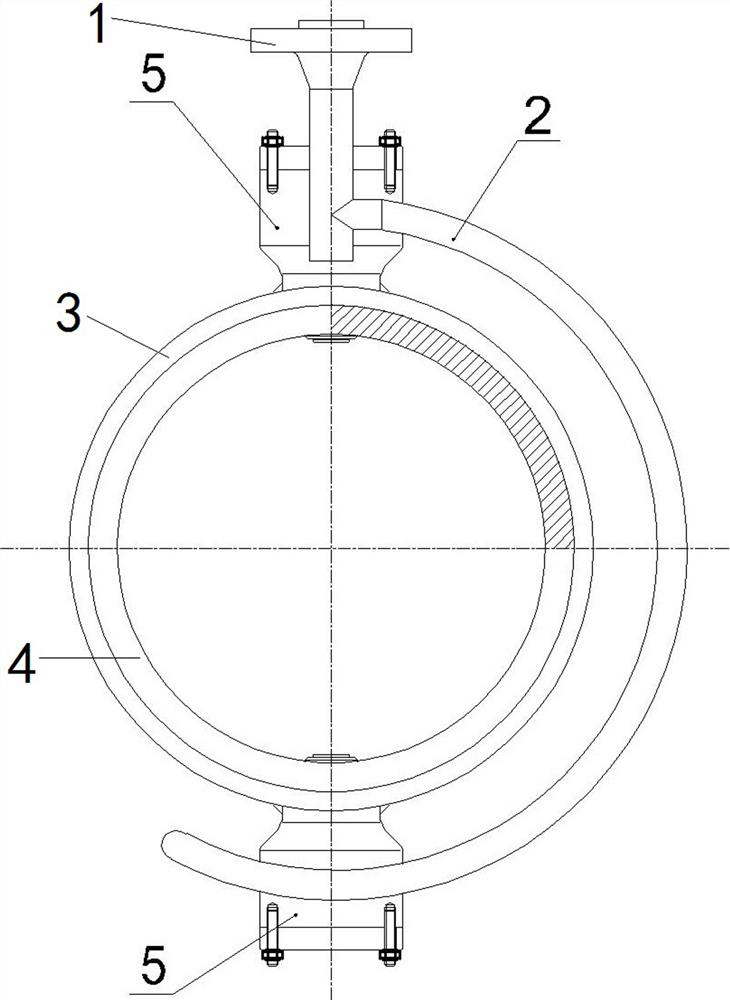

[0035] Combined attached Figure 1-6 A remote monitoring and multi-channel self-adjusting cooling system is specified

[0036] Medium pressure self-acting regulator 7-a pressure setpoint of 0.5MpaG, high pressure self-acting regulator 7-b pressure setpoint of 1MpaG.

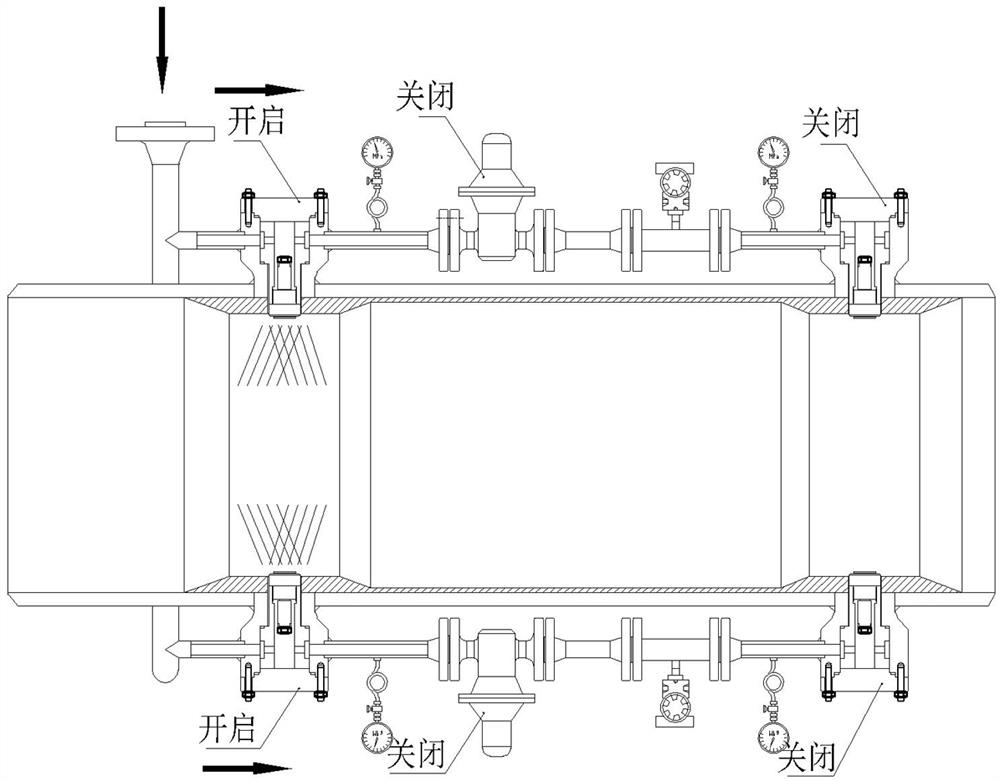

[0037] When the steam is small load, the temperature reduction water has a small flow, corresponding to the temperature reduction water pressure between 0 and 0.5MpaG, the temperature reduction water enters the two low-pressure nozzles through the ring-shaped dewarm water pipe 2, because the pressure value of the dethermal water is lower than 0.5MpaG, so the medium pressure self-acting regulator 7-a and the high-pressure self-acting regulator 7-b are in a closed state, and the actual nozzle is opened with a low-pressure nozzle 5.

[0038] When the steam is loaded, the reduced temperature water flow increases, and then the dethermal water pressure also increases between 0.5 and 1MpaG, the medium pressure se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com