Electric control system capable of burning production configuration file and control method thereof

A configuration file and electronic control system technology, applied in software deployment, software engineering design, electrical digital data processing, etc., can solve the problems of reduced production efficiency and increased difficulty of material control, so as to improve production efficiency and reduce the difficulty of material control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

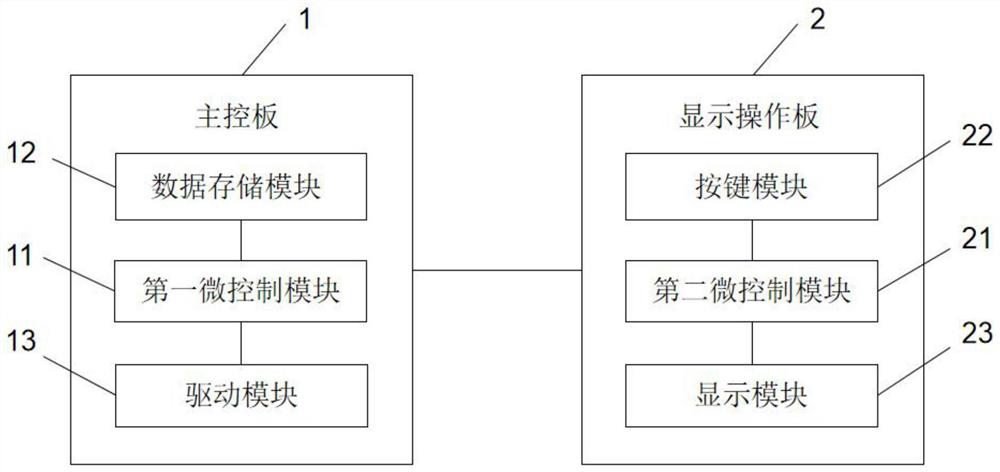

[0028] Embodiment 1 of the present invention provides an electronic control system capable of burning production configuration files, such as figure 1 As shown, it includes a main control board 1 and a display operation board 2, the display operation board 2 is electrically connected to the main control board 1, and the configuration file storage unit is provided in the main control board 1 for burning production including the Displays the configuration file of the corresponding relationship between keys and functions on the operation panel 2.

[0029] In this way, by setting the configuration file storage unit in the main control board 1, the configuration file can be burned into the configuration file storage unit of the main control board during the production process of the whole machine. Get the content of the configuration file in the configuration file storage unit, and execute the program logic according to the content of the configuration file (corresponding relations...

Embodiment 2

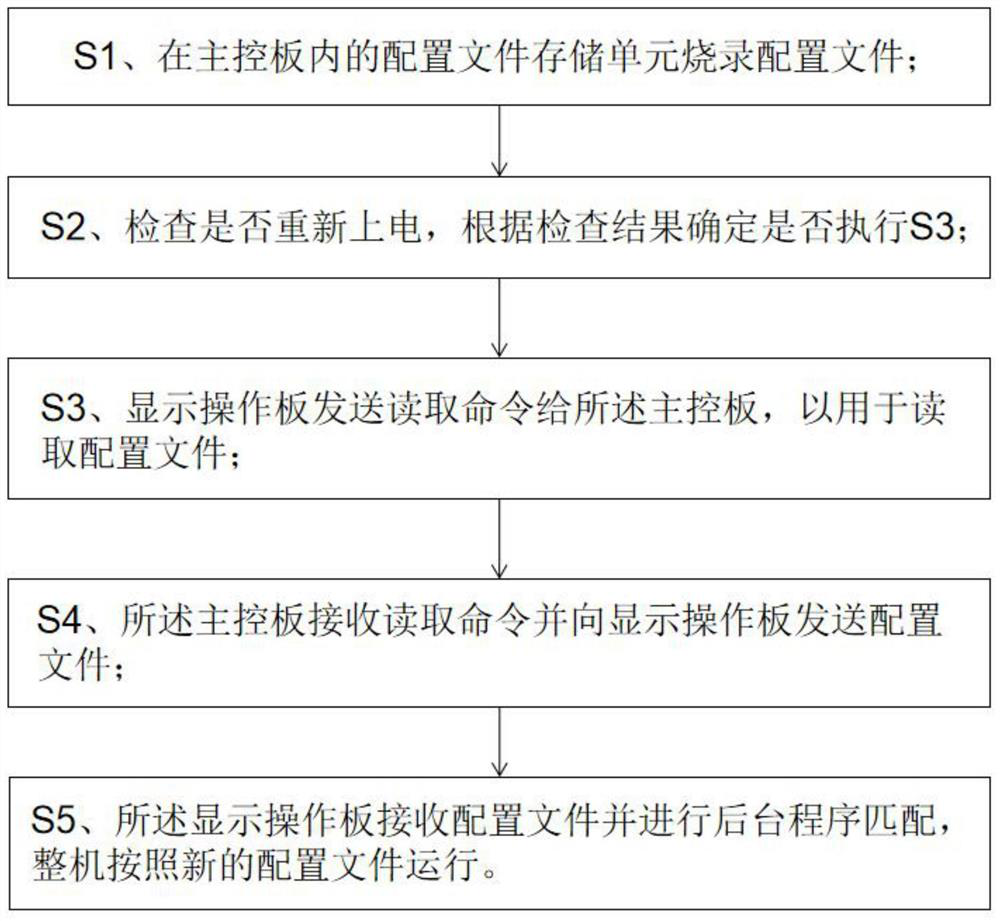

[0040] Such as figure 2As shown, Embodiment 2 of the present invention provides a control method of the electronic control system that can burn production configuration files, which is characterized in that it includes the following steps:

[0041] S1. Burn the configuration file in the configuration file storage unit in the main control board;

[0042] S2. Check whether to power on again, and determine whether to execute S3 according to the inspection result;

[0043] S3. The display operation board sends a read command to the main control board for reading the configuration file;

[0044] S4. The main control board receives the read command and sends the configuration file to the display operation board;

[0045] S5. The display operation panel receives the configuration file and performs background program matching, and the whole machine runs according to the new configuration file.

[0046] In this way, the production process of the whole machine is:

[0047] Step 1: ...

Embodiment example

[0058] A range hood that can burn production configuration files. There are 6 keys on the display panel, which are recorded as key[6]={0x01,0x02,0x03,0x04,0x05,0x06}. There are 10 optional functions , recorded as Fun1~Fun10:

[0059] Function definition correspondence table:

[0060] function definition corresponding code function definition corresponding code Switch function Fun1 0x01 Automatic cleaning function Fun6 0x06 Stir fry function Fun2 0x02 Quick cleaning function Fun7 0x07 Air volume function Fun3 0x03 Automatic memory function Fun8 0x08 Delay function Fun4 0x04 Screen lock function Fun9 0x09 Lighting function Fun5 0x05 Smart Start Function Fun10 0x0A

[0061] When defining the corresponding buttons and functions of this model as:

[0062] key number define function key number define function key1 Fun1 Key4 Fun2 Key2 Fun3 Key5 Fun4 Key3 Fun6 Key6 Fun5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com