Tool life prediction method, device and computer equipment based on edge computing

A tool life and edge computing technology, applied in computer-aided design, calculation, design optimization/simulation, etc., can solve the problems of inability to accurately know the tool life and reduce the qualified rate of the workpiece, and achieve efficient running time and improve the qualification rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

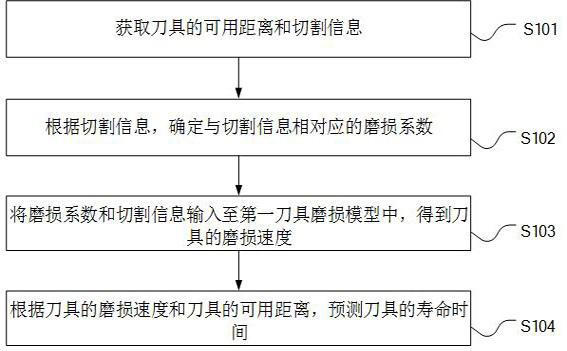

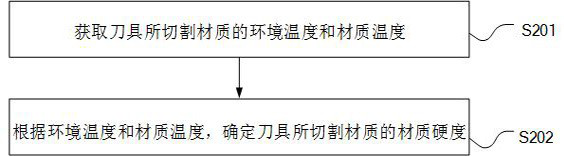

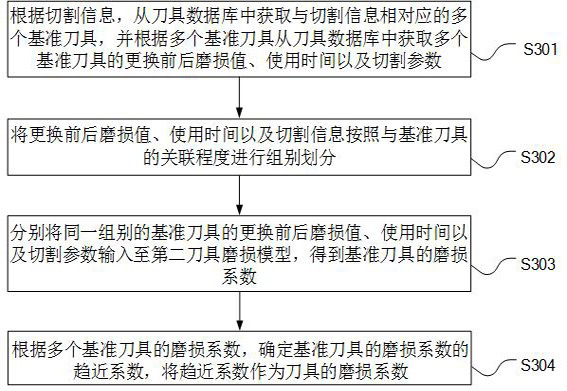

[0044] In metal cutting, the tool deforms the workpiece material and shears it off in the form of chips. The deformation process requires a lot of force. The tool is subjected to various mechanical, thermal, chemical and frictional loads. Over time, these loads Eventually the tool will have to be replaced due to excessive wear. By properly predicting tool life, manufacturers can plan metalworking processes precisely according to tool wear and thus control costs and avoid unplanned downtime due to unexpected tool failure behavior or unacceptable workpiece quality. Tool life modeling can help improve productivity and control costs in the manufacturing industry, where the key co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com