Process control method for glass plate tempering process

A technology of process and control method, which is applied in glass tempering, glass manufacturing equipment, temperature control, etc., and can solve the problems of energy waste, product quality, cooling fan starting too early, too late, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

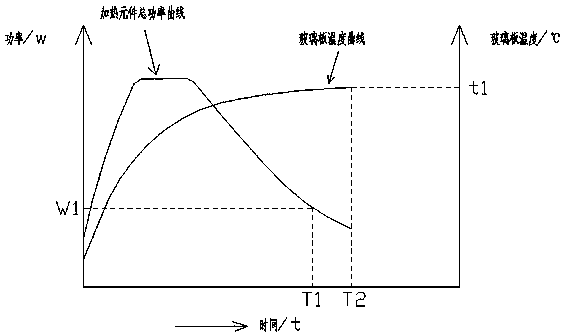

[0039] Such as figure 1 As shown, taking the total heating power of the electric heating element as an example, the control process of the control method of the present invention is as follows:

[0040] First, determine the heating furnace to be used, adjust the working temperature of the heating furnace according to the type of glass plate to be heated (such as low-emissivity coated glass, clear glass) and thickness information, and run the heating furnace under no-load when the ambient temperature is normal temperature When the working temperature is reached, monitor the total power value of the heating element in this state, measure the total power value at five different times, and calculate the average value of the five values, which is the normal temperature threshold W 常 , and then determine the correction factor M according to the advance operation of the cooling fan W ,M W The range of values is M W ≥1.1, preferably 1.1≤M W ≤1.3. Measure the ambient temperature...

Embodiment 2

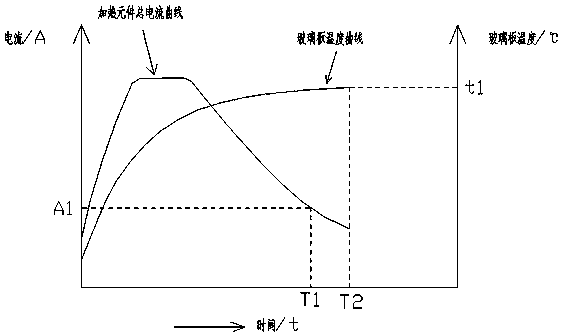

[0043] Such as figure 2 As shown, taking the total current of the electric heating element as an example, the control process of the control method of the present invention is as follows:

[0044] First determine the heating furnace to be used, adjust the working temperature of the heating furnace according to the type of glass plate to be heated (such as low-emissivity coated glass, clear glass) and thickness information, and run the heating furnace under no-load operation when the ambient temperature is normal temperature. Working temperature, monitor the total current of the heating element in this state, measure the total current at five different times, and calculate the average value of the five values, the average value is the normal temperature threshold A 常 , and then determine the correction factor M according to the advance operation of the cooling fan A ,M A The range of values is M A ≥1.1, preferably 1.1≤M A ≤1.3. Measure the ambient temperature, and compa...

Embodiment 3

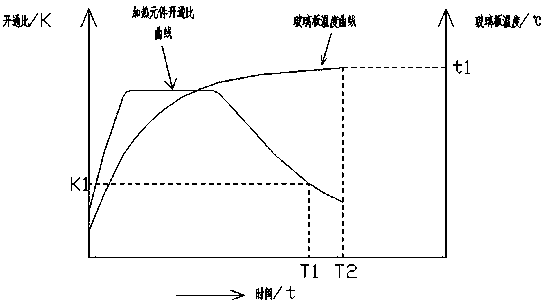

[0047] Such as image 3 As shown, taking the opening ratio of the electric heating element as an example, the control process of the control method of the present invention is as follows:

[0048] First determine the heating furnace to be used, adjust the working temperature of the heating furnace according to the type of glass plate to be heated (such as low-emissivity coated glass, clear glass) and thickness information, and run the heating furnace under no-load operation when the ambient temperature is normal temperature. Working temperature, monitor the opening ratio of the heating element in this state, measure the opening ratio at five different times, and calculate the average value of the five values, the average value is the normal temperature threshold K 常 , and then determine the correction factor M for the cooling fan to run in advance K ,M K The range of values is M K ≥1.1, preferably 1.1≤M K ≤1.3. Measure the ambient temperature, and compare the correction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com