Efficient tea strip forming pot

A high-efficiency, tea-leaf technology, applied in the direction of pre-extraction tea treatment, etc., can solve the problems of low work efficiency and unsatisfactory sliver effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

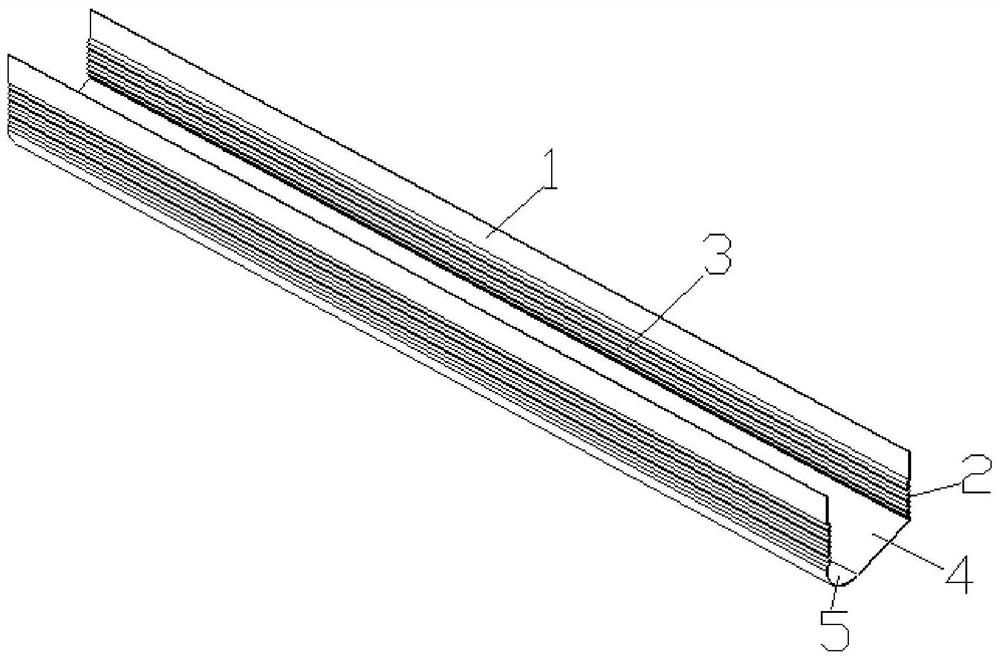

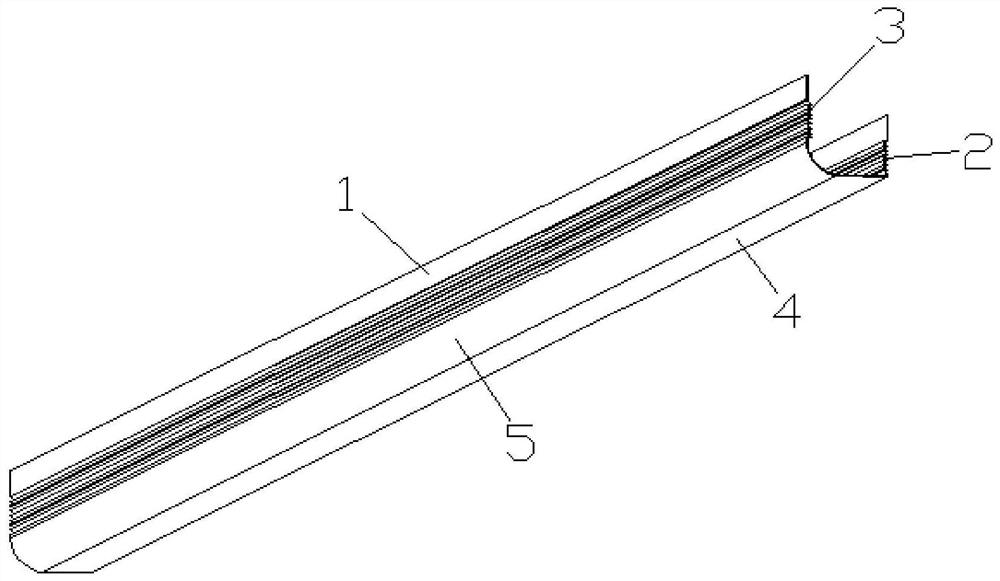

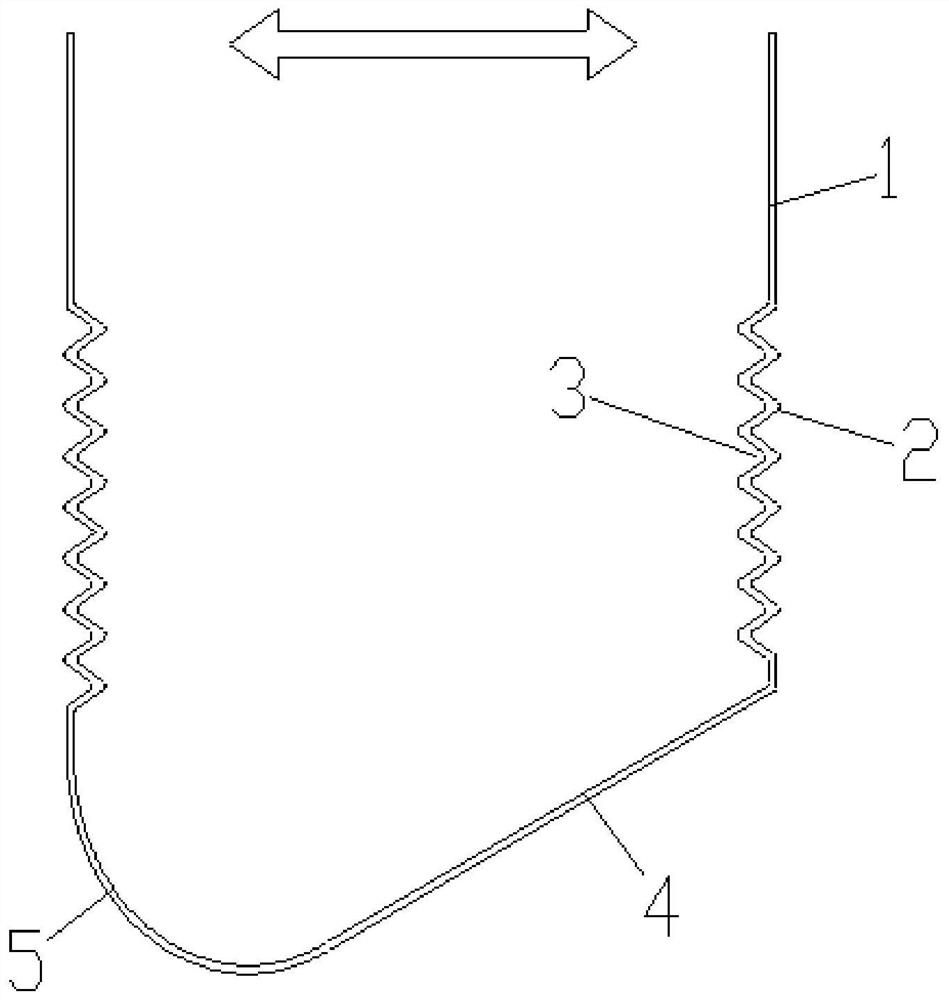

[0019] Such as Figure 1-Figure 3 As shown, the high-efficiency teapot forming pot includes a pot body composed of a pot bottom and vertical side walls 1 on the left and right sides. The whole pot body reciprocates in the left and right directions (as shown by the double arrows in the figure). The lower section 2 of the side wall 1 is respectively formed into a serpentine body, so that the inner and outer walls of the lower section 2 of the side wall 1 are respectively formed with a plurality of tooth-shaped shaping grooves 3 distributed continuously in the vertical direction.

[0020] The bottom of the pot is divided into two sections, wherein the right section is the slope section 4, the slope section 4 is used as the tea turning part, and the left section is the arc section 5, and the arc section 5 is used as the tea turning section. The slope secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com