Soft base mesh production process

A production process, a technology of soft-based nets, applied in textiles and papermaking, braided fabrics, heating/cooling fabrics, etc., can solve problems that affect normal growth, affect the normal growth of flowers and seeds, and reduce the warp distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The invention is specifically described below by way of examples.

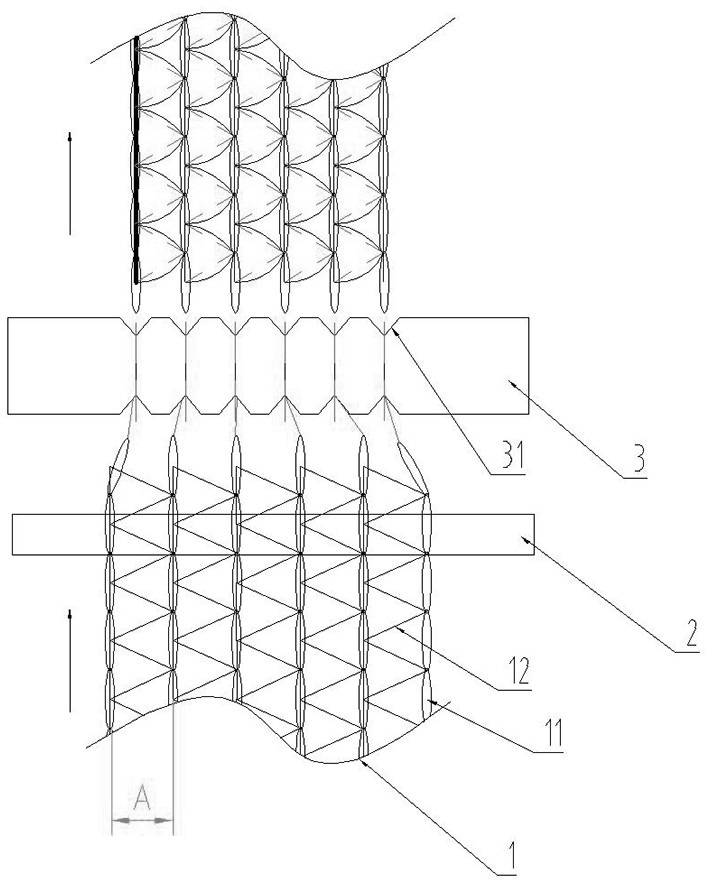

[0010] like figure 1 As shown, a kind of soft base net 1 production process of the present invention comprises the following steps: a, the weaving machine weaves the base net 1, the base net 1 material is HDPE, the base net 1 has warp 11 and weft 12, adjacent warp The distance between 11 is A, and the weft 12 is staggered between two adjacent warps 11 to form a triangular mesh; b, the base web 1 passes through the high-temperature roller surface of the heating roller 2 at a certain linear speed, and the warp After contacting with the high-temperature roller surface of the heating roller 2, high-temperature shaping is obtained without weft thread, and the warp stretch rate after high-temperature shaping is not more than 5%; c, the base web 1 is wound in such a way that the distance between adjacent warp threads 11 becomes smaller , the distance between adjacent warp threads 11 after winding is 70%~80% o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com