A butterfly valve, a method for rotatably locking a disc of a butterfly valve and use of a butterfly valve

A technology of butterfly valves and butterfly plates, which is applied in the direction of lifting valves, valve devices, engine components, etc., can solve the problems of incorrect positioning of parts, difficult correct installation and disassembly of wedges, etc., and achieve safe locking, firm fixing, and risk reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

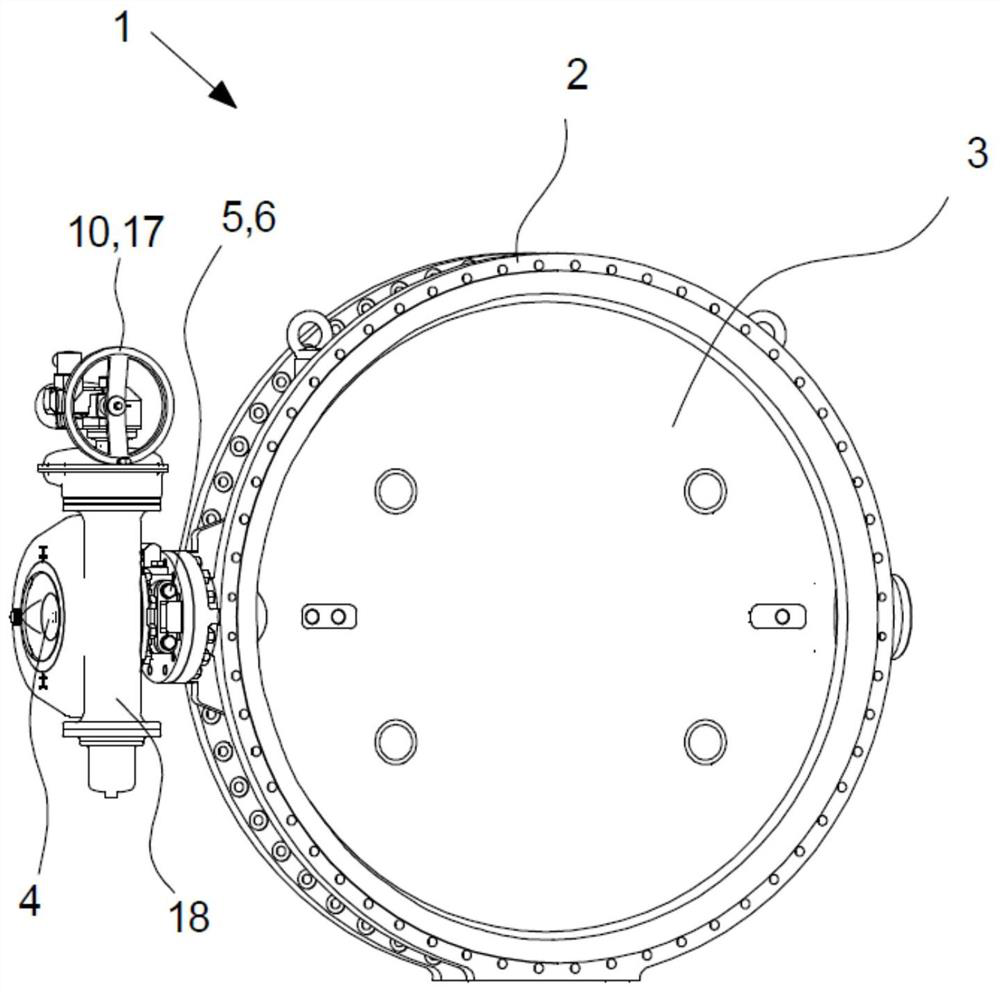

[0062] figure 1 The butterfly valve 1 is shown, as seen in perspective view.

[0063] In this embodiment, the butterfly valve 1 includes a butterfly plate 3 suspended on both sides but only provided with a transmission device 10 on one side. However, in another embodiment, the butterfly plate 3 could be provided with transmissions 10 on both sides, or the butterfly plate 3 would only be suspended on one side, for example, if the transmission 10 was arranged on the top of the butterfly plate 3 instead of the side.

[0064] In this embodiment, the drive means 10 comprise a handle 17 arranged to act on the drive shaft 4 via a gear 18, in this case a worm gear. However, in another embodiment, the transmission 10 may comprise a lever, drive, motor, or other device and / or the transmission 10 may be adapted in another manner (such as by a chain or belt drive, planetary gears, spur gears, or other device). ) and / or butterfly valve 1 does not contain gear 18.

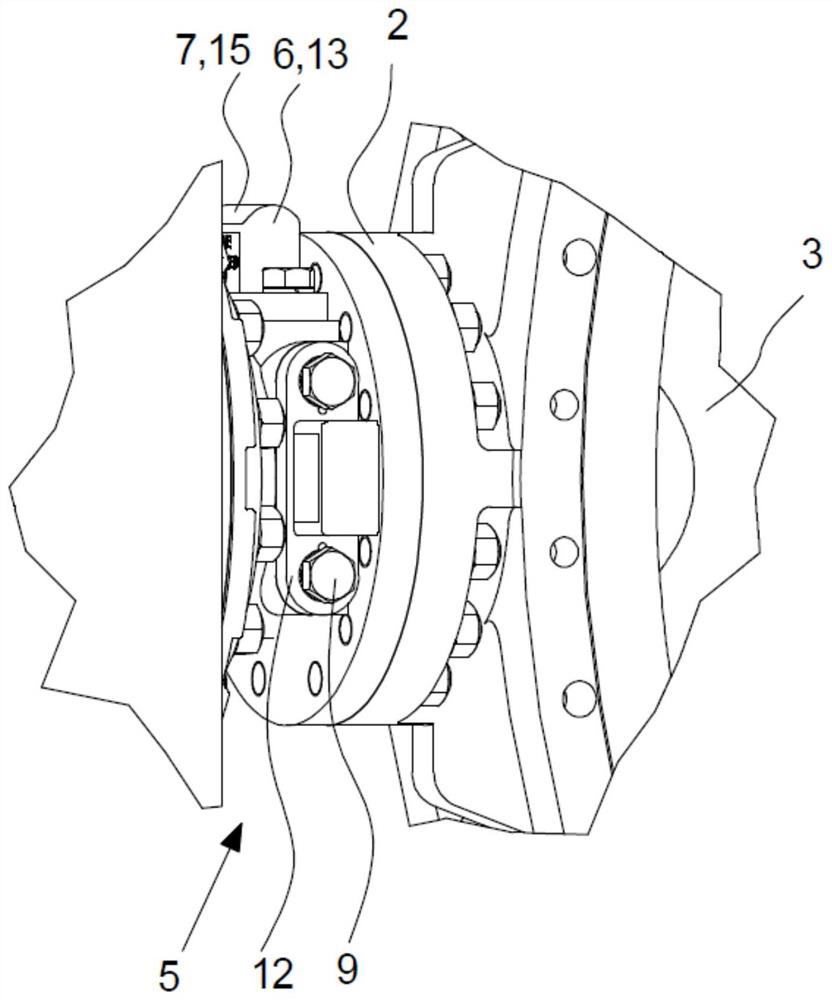

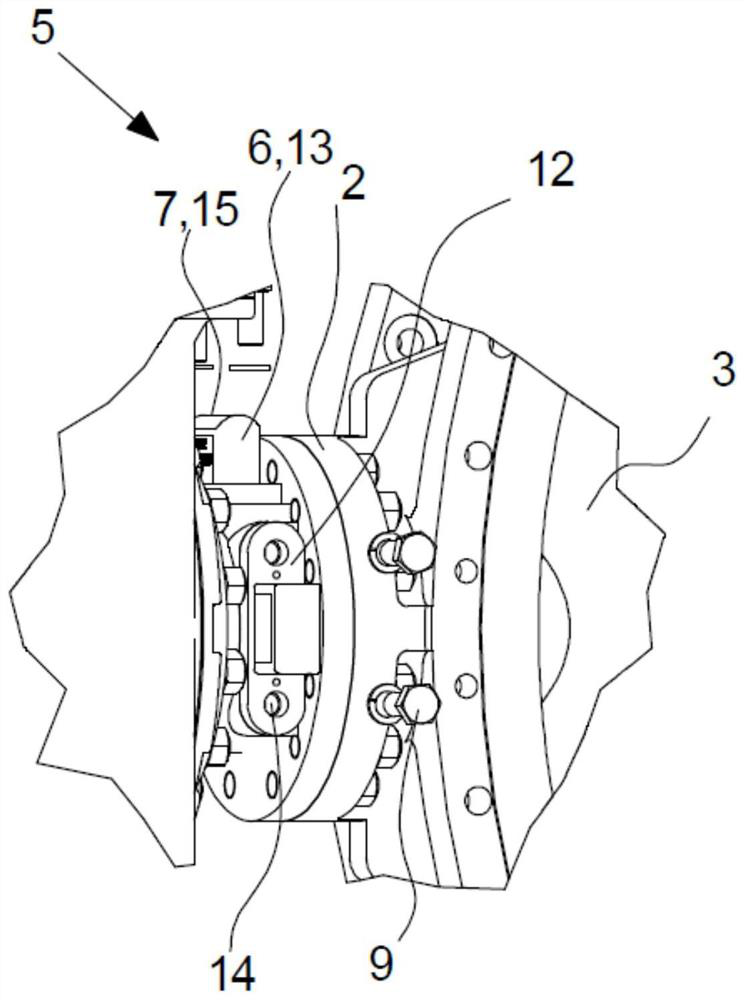

[0065] In this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com