Device for correcting ovality of port of large elbow pipe fitting

An elbow pipe and ellipticity technology, which is applied in the field of devices for correcting the ellipticity of large-scale elbow pipe fittings, can solve the problems of high energy consumption, high noise, and high working environment temperature, and achieve the effect of ensuring work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

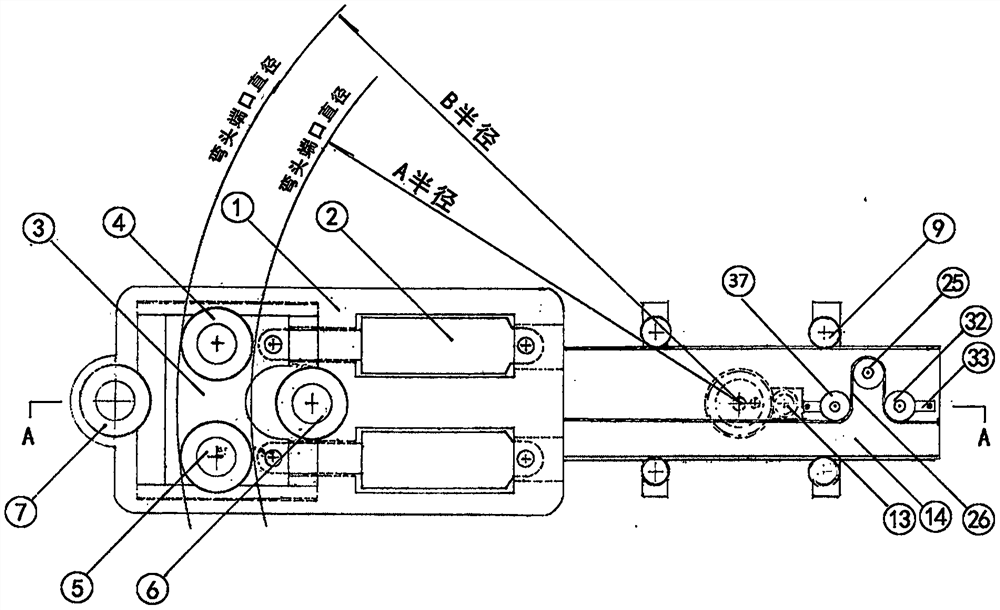

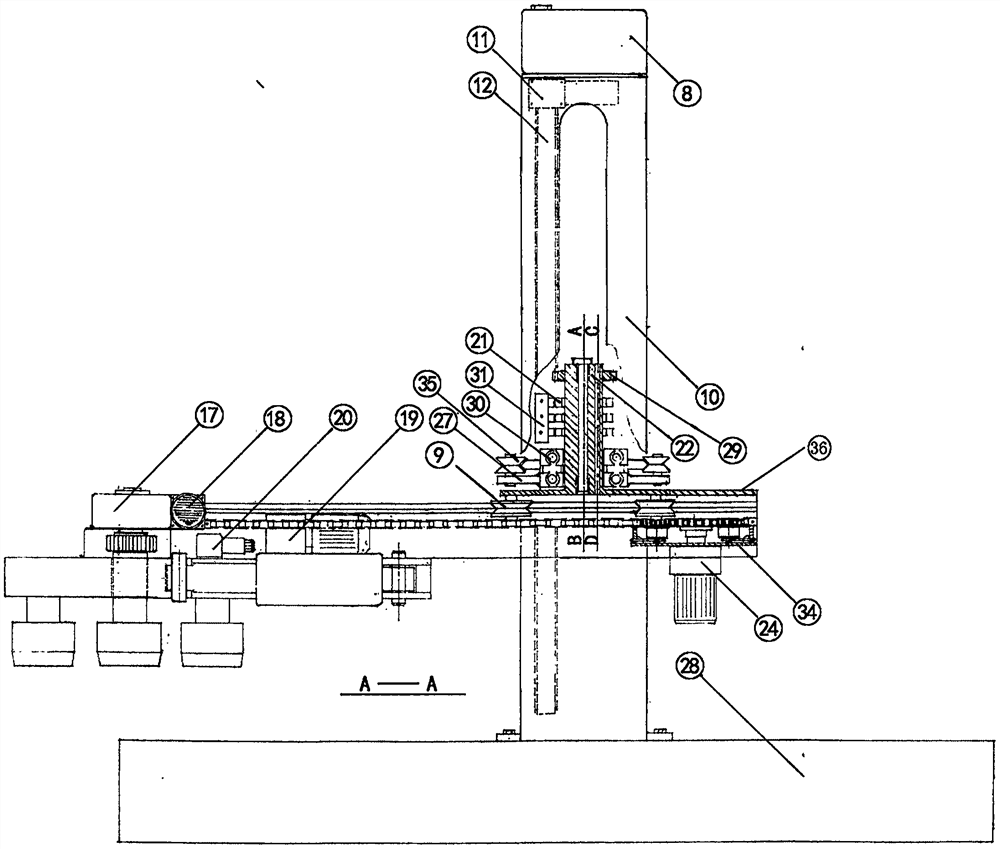

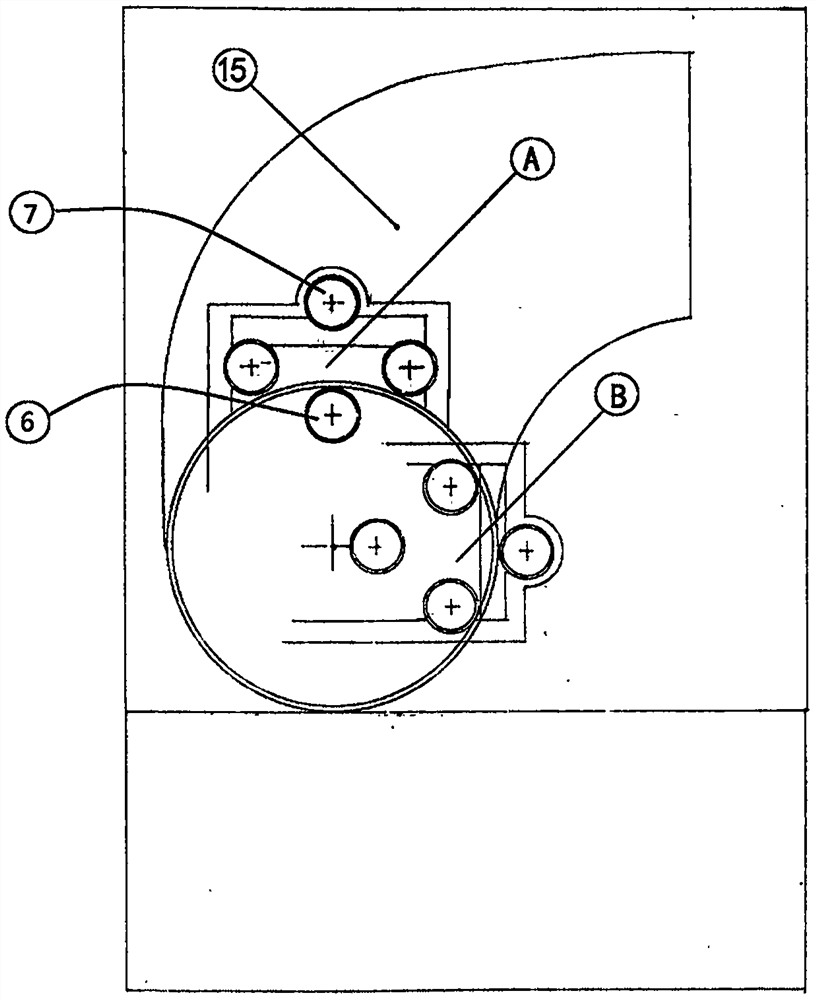

[0023] like figure 1 As shown, driving wheels 4, 5, a first driven wheel 6, and a second driven wheel 7 are arranged on the circle calibration body 1. The driving wheel can move left and right relative to the driven wheel, and the driving wheel and the driven wheel cooperate to clamp the elbow port to carry out Elbow port calibration; the first driven wheel 6 is used to correct the concave position in the elbow port, and the outer side of the first driven wheel 6 is provided with an arc-shaped shell, and the second driven wheel 7 is used to correct the convex position in the elbow port. Starting position; two driven wheels are respectively positioned at both sides of the driving wheel, and the axles of the first driven wheel 6, the second driven wheel 7, and the driving wheel are arranged parallel to each other. The line connecting the positions of the two driving wheels 4 and 5 is perpendicular to the line connecting the positions of the two driven wheels.

[0024] like fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com