Mounting method and mounting tool for pipe of gas collecting platform of chemical tanker

A technology for installing chemical tankers and pipes, which is applied in the direction of manufacturing tools, metal processing, auxiliary equipment, etc., can solve the problems of poor welding quality of finished pipes, difficulty in meeting design requirements, poor pipe control effects, etc. wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Next, we will further elaborate on the method and installation tools for the installation of gas-gathering platform pipes on a chemical tanker according to the present invention in combination with the accompanying drawings and specific embodiments, in order to understand its structural composition and implementation methods more clearly. But can not limit the protection scope of the present invention with this.

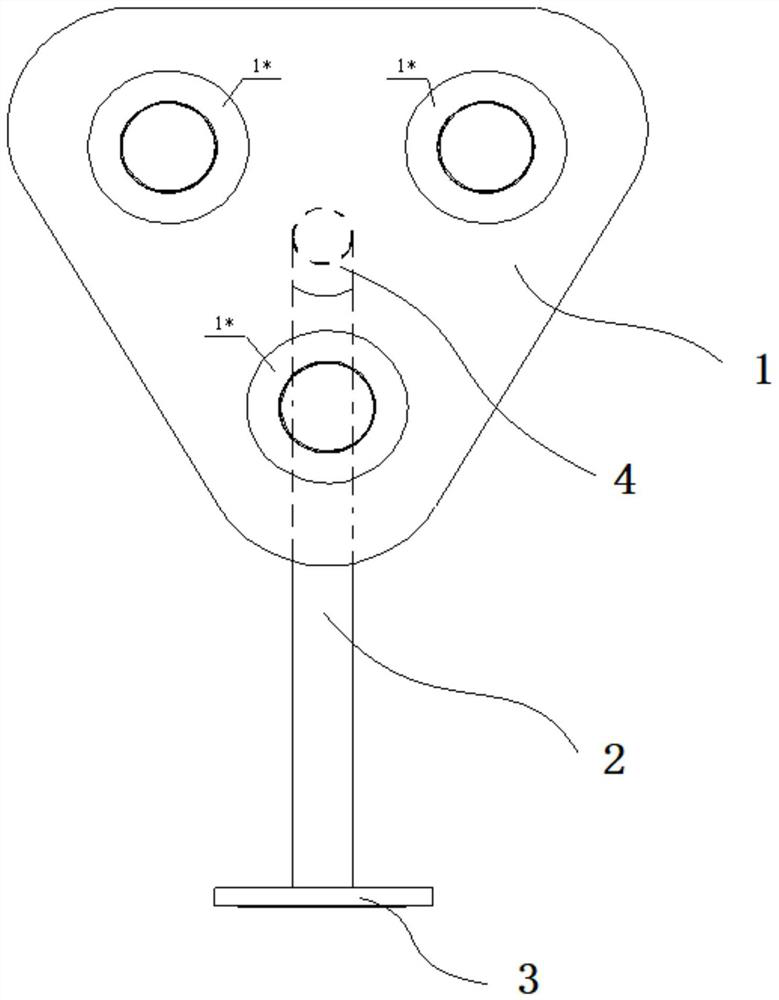

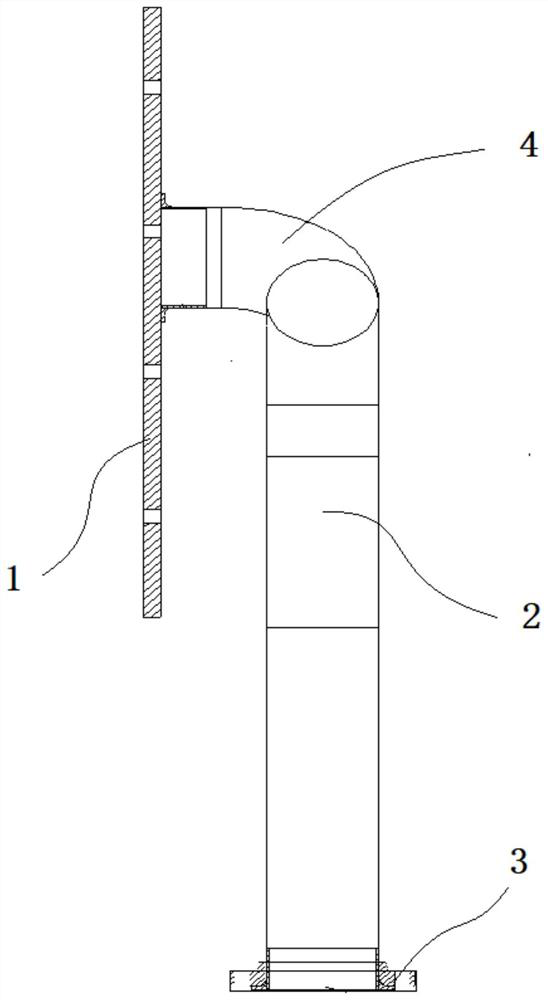

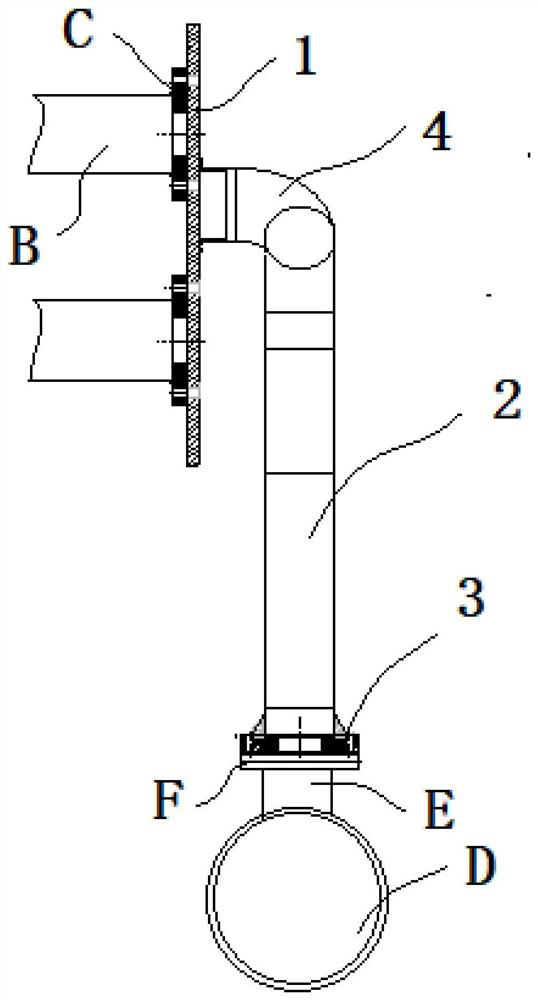

[0030] The present invention firstly provides a method for installing pipes on a gas-gathering platform on a chemical ship. There are multiple cargo tanks on the chemical tanker, and each cargo tank is provided with a shore joint A that extends independently to the gas-gathering platform. A includes a joint short pipe B and a side flange C. The flange faces of the bank joint A on the gas gathering platform are all in the same plane. The bank joint A is arranged in two rows up and down. A main pipe D of the liquid cargo pipe is provided, and a row of upward bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com