A method for precise positioning of the track of the trolley with the shaft entering the stern of the ship

A technology of precise positioning and trolley track, which is applied in the direction of warships, etc., can solve the problems of different centerlines, fluctuations in the front and rear directions, misalignment between the center of the stern shaft tube and the centerline of the shaft system, etc., to ensure product quality and reduce investment costs Low, improve the effect of core competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

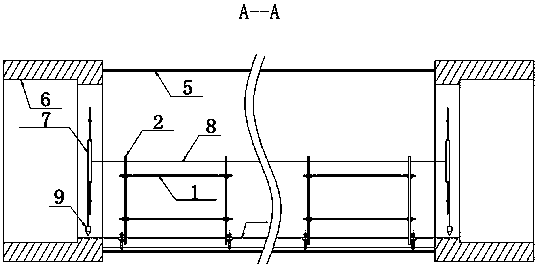

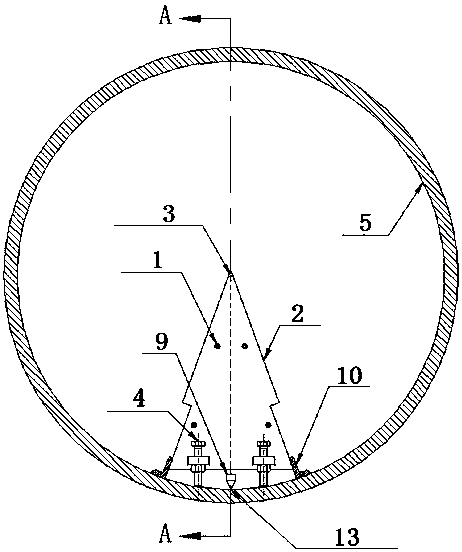

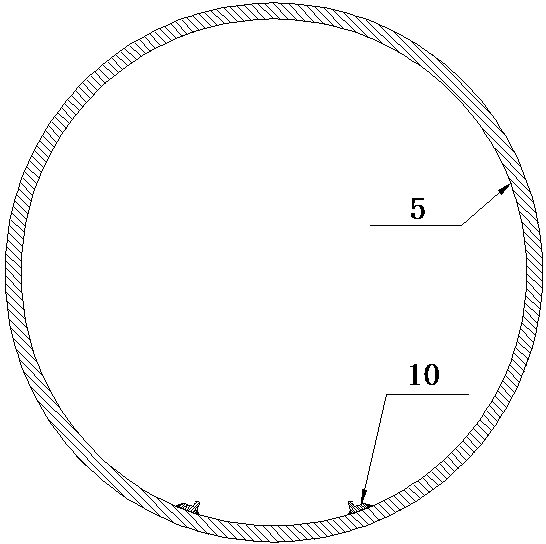

[0031] A method for precise positioning of the trolley track at the tail of a ship according to the present invention will be further described in detail in conjunction with the accompanying drawings and examples, in order to understand its structural composition and working mode more clearly, but it cannot be used to limit the present invention. The protection scope of the invention patent.

[0032] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a method for precise positioning of the track of the shaft-incoming trolley at the tail of the ship, the method includes the following steps:

[0033] Step 1: install several groups of assemblies, the assemblies include several distance screw rods 1 and two positioning plates 2, the two positioning plates 2 are parallel to each other, the positioning plates 2 are axisymmetric structures, and the The top of the plate surface of the positioning plate 2 is provided with an axis hole 3, and the center of the axis hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com