Aluminum-plastic material recycling device

A material recycling and processing device technology, applied in the field of aluminum-plastic materials, can solve problems such as easy spillage of milk, breeding of bacteria, machine pollution, etc., and maximize the effect of space utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

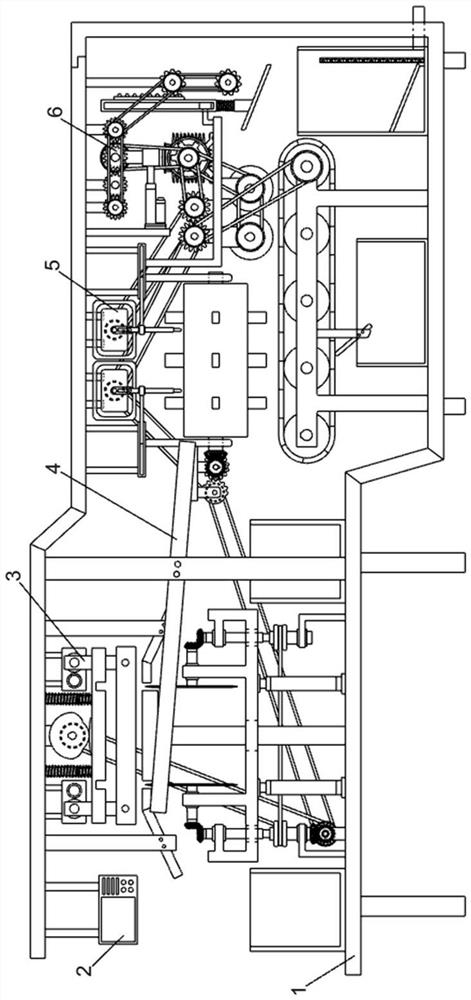

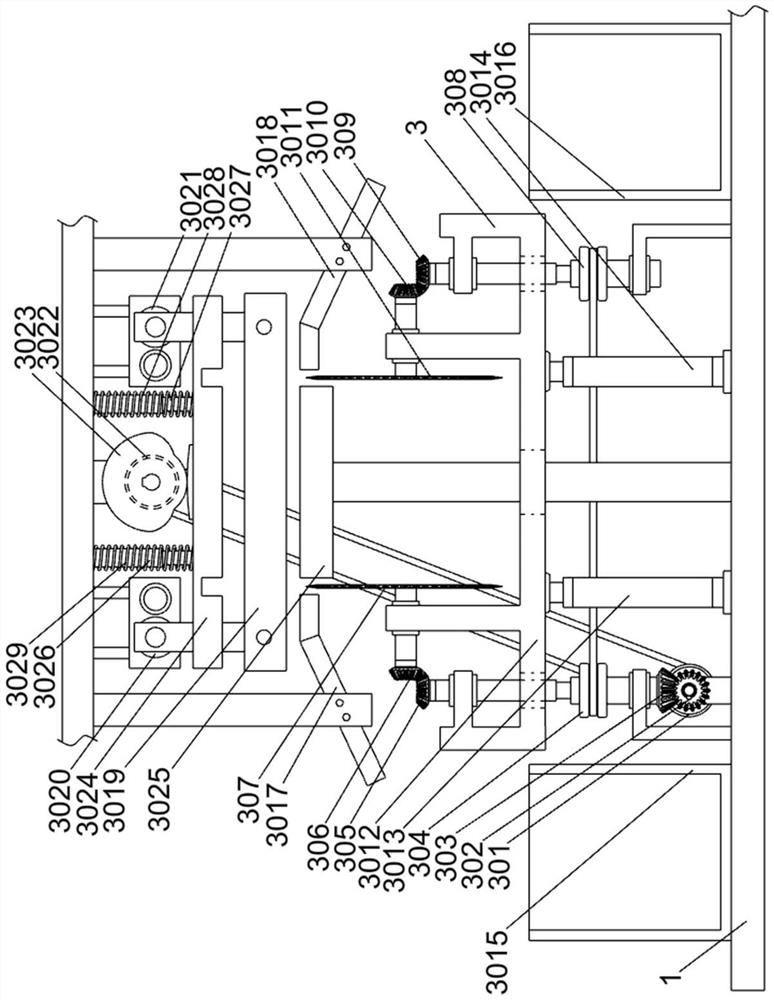

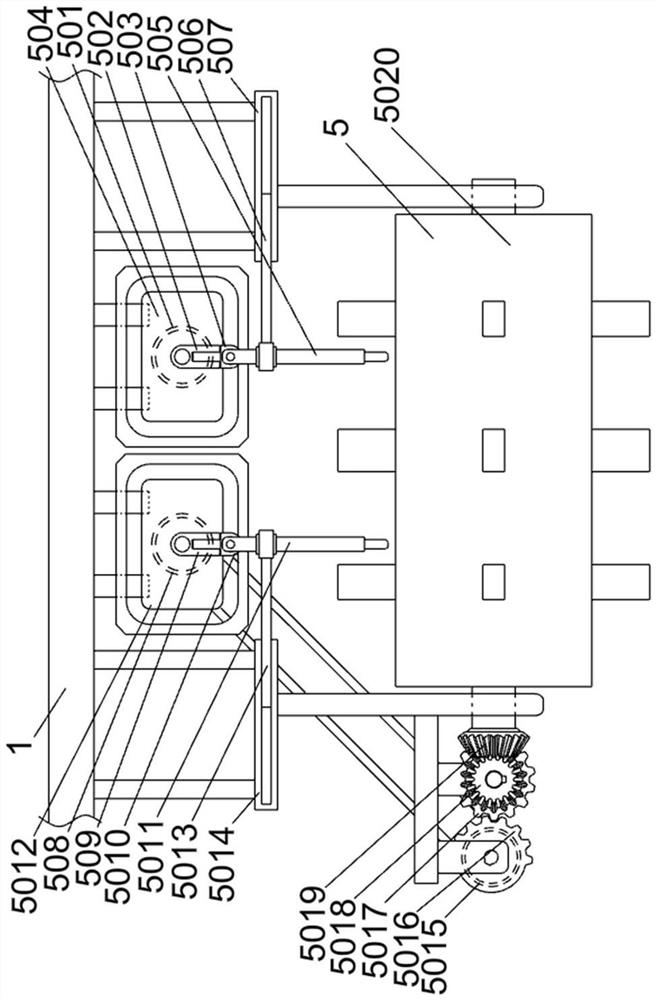

[0023] A kind of aluminum-plastic material recycling processing device, such as Figure 1-4 As shown, it includes a work frame plate 1, a control display screen 2, a cutting mechanism 3, a blanking plate 4, a material extrusion mechanism 5 and a collection mechanism 6; the work frame plate 1 is connected with the control display screen 2 through a support seat; the work frame The plate 1 is connected with the cutting mechanism 3; the working frame plate 1 is connected with the blanking plate 4; the working frame plate 1 is connected with the extruding mechanism 5; the working frame plate 1 is connected with the collecting mechanism 6; Mechanism 5 is connected; extruding mechanism 5 is connected with collecting mechanism 6.

[0024] Working principle: When using the device, the device is horizontally fixed at a reasonable position to be used through the working frame plate 1, and the external power supply is connected. The operator adjusts the device through the control display...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap