PCB detection and review method and device, electronic equipment and storage medium

A detection method and detection point technology, applied in electrical digital data processing, computer-aided design, special data processing applications, etc., can solve the problems of increased average cost of PCB board repair, repeated use of testing equipment, and different detection coverage. Achieve the effect of promoting smooth detection, avoiding repeated detection, and ensuring detectability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

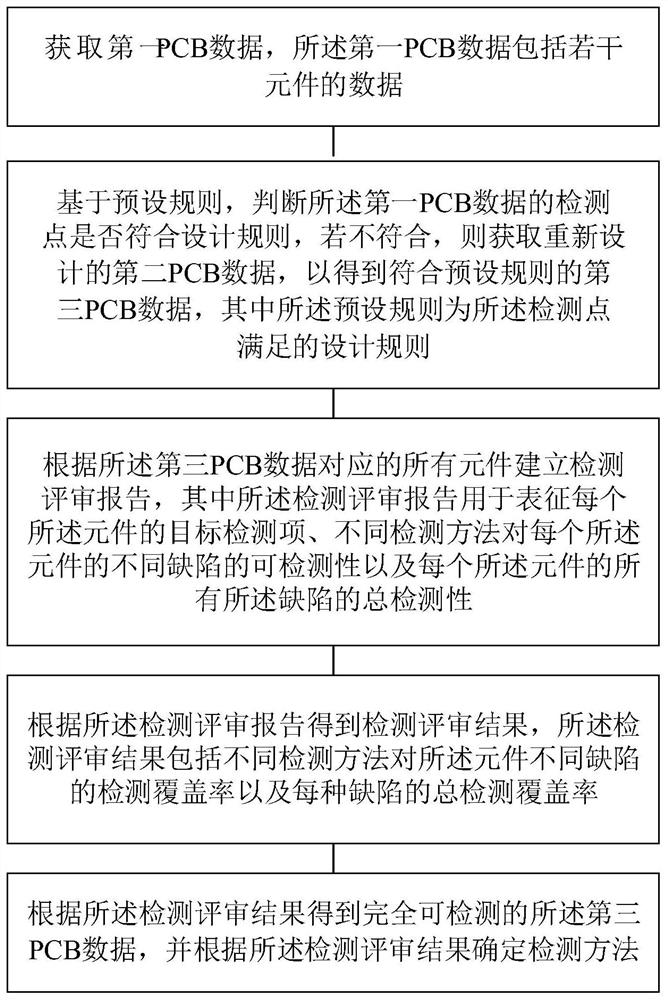

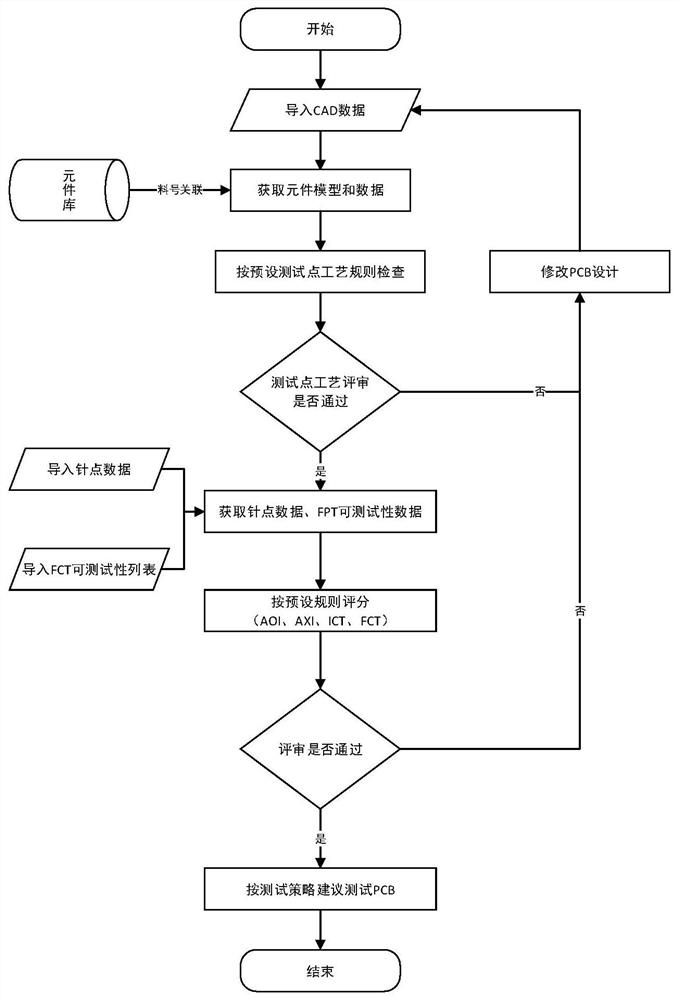

[0061] See figure 1 and figure 2 Understand the technical solution of this embodiment. This embodiment provides a method for PCB inspection and review, which may specifically include:

[0062] Step 1, obtaining the first PCB data, the first PCB data includes the data of several components;

[0063] Step 2. Based on the preset rules, judge whether the detection point of the first PCB data conforms to the design rules, and if not, obtain the redesigned second PCB data to obtain the third PCB data conforming to the preset rules, wherein the preset The rule is the design rule that the detection point satisfies;

[0064] Step 3. Establish a test review report based on all components corresponding to the third PCB data, wherein the test review report is used to characterize the target test items of each component, the detectability of different defects of each component by different detection methods, and the The total detectability of all defects in ;

[0065] Step 4. Obtain ...

Embodiment 2

[0136] See Figure 9 , Figure 9 It is a schematic structural diagram of a PCB inspection and evaluation device provided in this embodiment. The PCB inspection review device includes:

[0137] An acquisition module, configured to acquire first PCB data, where the first PCB data includes data of several components;

[0138] The design module is used to judge whether the detection point of the first PCB data conforms to the design rules based on the preset rules, and if not, obtain the redesigned second PCB data to obtain the third PCB data conforming to the preset rules, wherein The preset rule is the design rule satisfied by the detection point;

[0139] The detection review report building module is used to establish a test review report based on all components corresponding to the third PCB data, wherein the test review report is used to characterize the target detection items of each component, and the detectability of different defects of each component by different det...

Embodiment 3

[0144] See Figure 10 , Figure 10 It is a schematic structural diagram of an electronic device provided in this embodiment. The electronic device 1100 includes: a processor 1101, a communication interface 1102, a memory 1103, and a communication bus 1104, wherein the processor 1101, the communication interface 1102, and the memory 1103 complete mutual communication through the communication bus 1104;

[0145] memory 1103, for storing computer programs;

[0146] The processor 1101 is configured to implement the above method steps when executing the computer program.

[0147] When the processor 1101 executes the computer program, the following steps are implemented:

[0148] Step 1, obtaining the first PCB data, the first PCB data includes the data of several components;

[0149] Step 2. Based on the preset rules, judge whether the detection point of the first PCB data conforms to the design rules, and if not, obtain the redesigned second PCB data to obtain the third PCB data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com