Suspender type damp-proof container bag and manufacturing method thereof

A production method and container bag technology, which is applied in the field of container bags, can solve problems such as easy scattering of crops, and achieve the effect of avoiding cross-mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

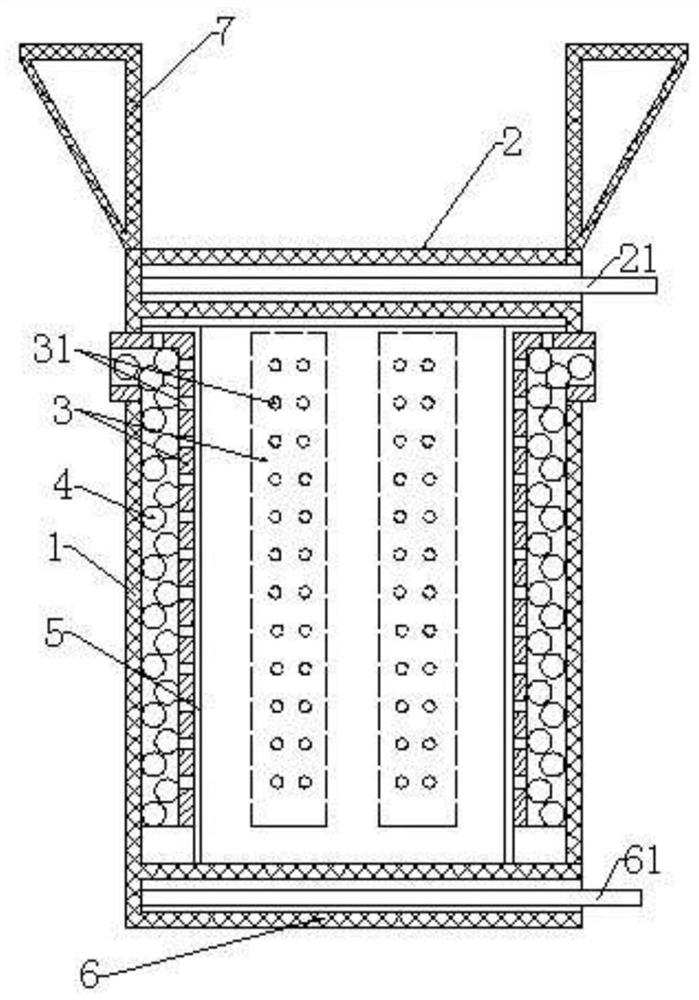

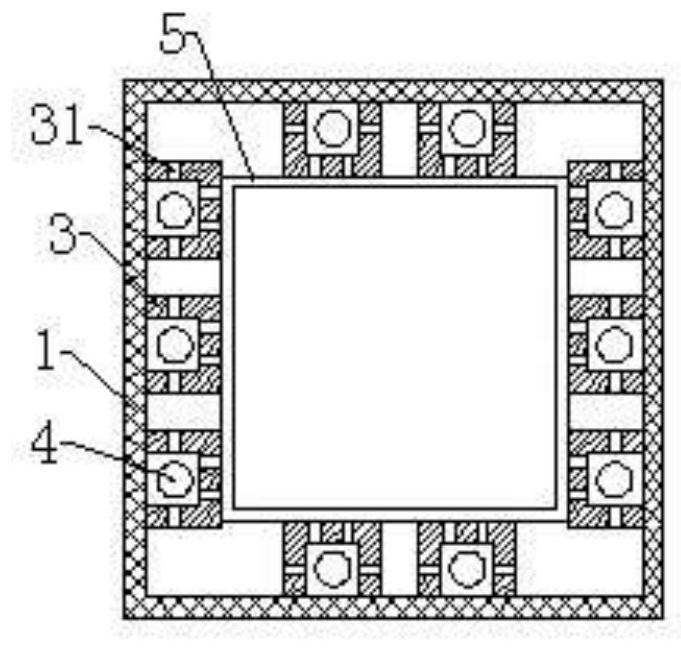

[0019] Such as figure 1 and 2 As shown, the sling-type moisture-proof container bag of the present invention includes a bag body 1 and a feed port 2, and a plurality of vertically arranged hollow groove-shaped spacers 3 are arranged on the inside of the side wall of the bag body 1, and the hollow groove-shaped spacers The bottom end of 3 extends to the bottom close to the bag body 1, and the top of the hollow groove-shaped spacer 3 stretches out of the bag body 1, and the surface of the hollow groove-shaped spacer 3 is evenly distributed with air holes 31, and the surface of the hollow groove-shaped spacer 3 is evenly distributed. 3 is filled with granular edible desiccant 4 . In this embodiment, the top of the hollow groove-shaped spacer 3 is bent and protrudes from the upper side wall of the bag body 1 . An air-permeable cloth 5 is arranged on the inside of the side wall of the bag body 1 , and the hollow groove-shaped spacer 3 is located between the air-permeable cloth 5 ...

Embodiment 2

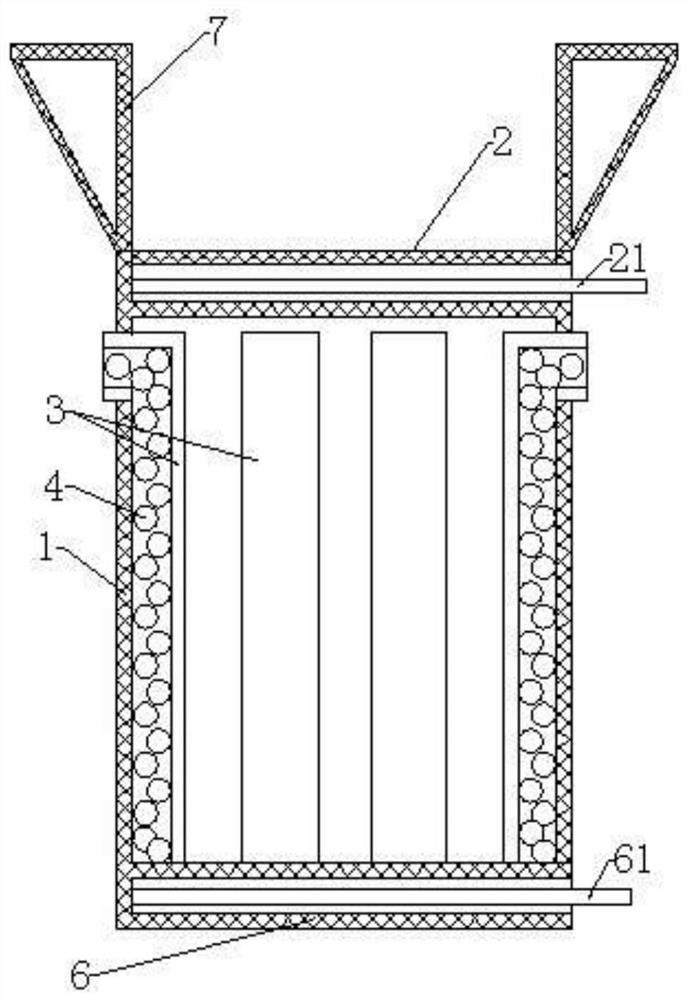

[0021] Such as image 3 and Figure 4 As shown, the sling-type moisture-proof container bag of the present invention includes a bag body 1 and a feed port 2, and a plurality of vertically arranged hollow groove-shaped spacers 3 are arranged on the inside of the side wall of the bag body 1, and the hollow groove-shaped spacers The bottom end of 3 extends to the bottom close to the bag body 1, the top of the hollow groove-shaped spacer 3 protrudes from the outside of the bag body 1, and the hollow groove-shaped spacer 3 is filled with granular edible desiccant 4. The hollow trough-shaped spacer is made of breathable cloth, and its low end and top end are closed structures to prevent the edible desiccant from scattering. The top of the hollow groove-shaped spacer 3 is bent and protrudes from the side wall of the upper part of the bag body 1 . A discharge port 6 is arranged at the bottom of the bag body 1 to facilitate the unloading of the container bag. At the same time, closi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com