Precast concrete cofferdam and pier construction process

A prefabricated concrete and cofferdam technology, applied in bridge construction, bridges, buildings, etc., can solve the problems of bridge pier construction time and construction cost increase, and achieve the effects of good sealing, time saving and convenient time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The following is attached Figure 1-8 The application is described in further detail.

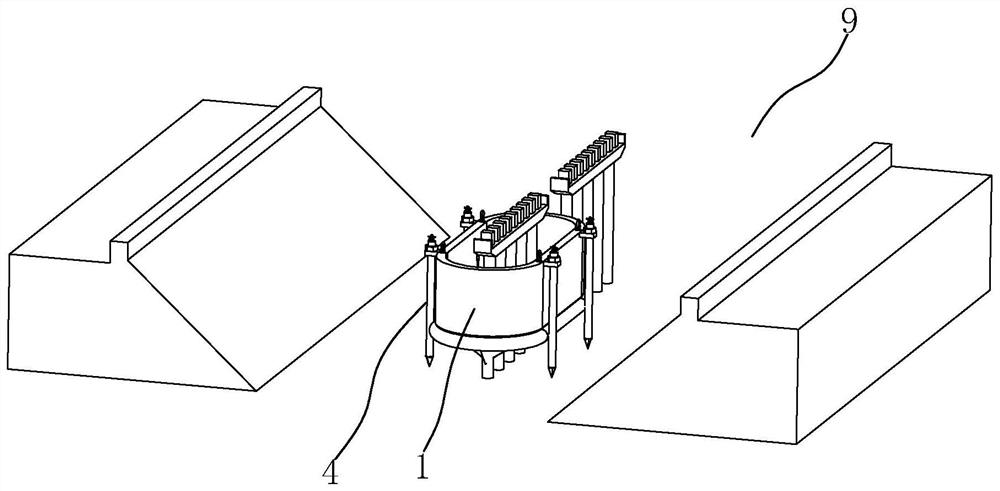

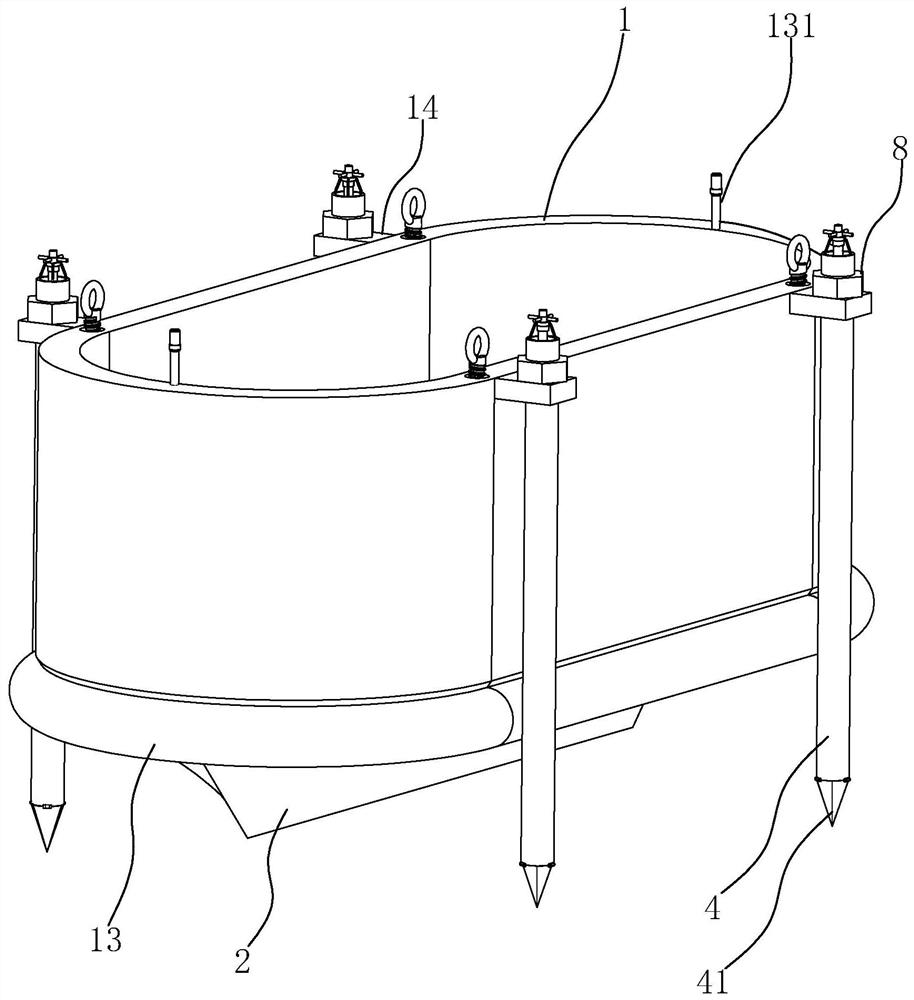

[0049] refer to figure 1 , figure 2 , the embodiment of the present application discloses a prefabricated concrete cofferdam, which is suitable for shallow water areas such as small rivers 9, and includes a tubular cofferdam main body 1, which is formed by pouring concrete.

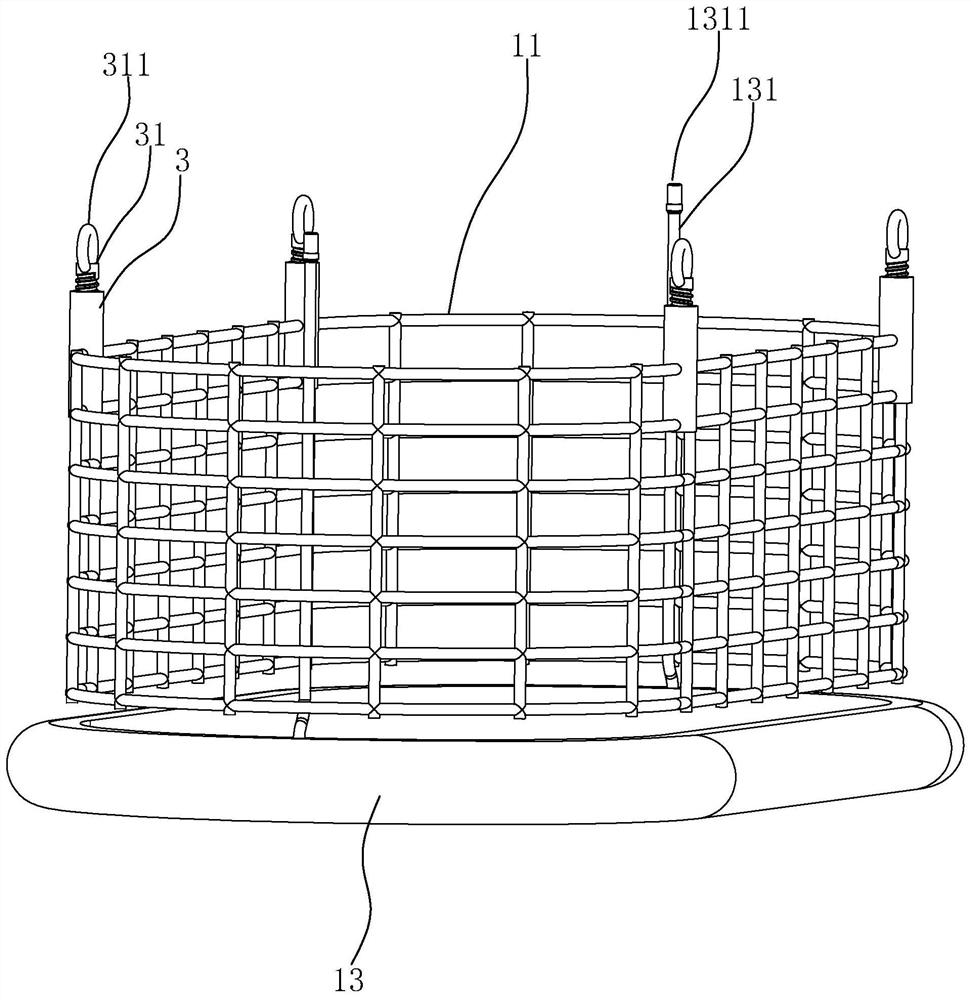

[0050] refer to image 3 , Figure 4 , The cofferdam main body 1 is embedded with a reinforced skeleton 11 . An annular support plate 12 is fixedly connected to the inner peripheral surface of the cofferdam main body 1, and a pressure water plate 2 is also arranged in the cofferdam main body 1. 12 are fixed by wearing waterproof bolts, and waterproof treatment is done between the pressure water plate 2 and the support plate 12.

[0051] When laying the cofferdam, the staff first lifts the cofferdam main body 1 into the water, and makes the cofferdam sink to the bottom of the water, and then the staff remove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com