A highway culvert structure and construction method

A technology for culverts and highways, which is applied in the field of highway culvert structures and construction, which can solve the problems of weak support capacity of culvert structures and easy occurrence of road laying, etc., and achieve the effects of convenient modular transportation, improved convenience of use, and stable driving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

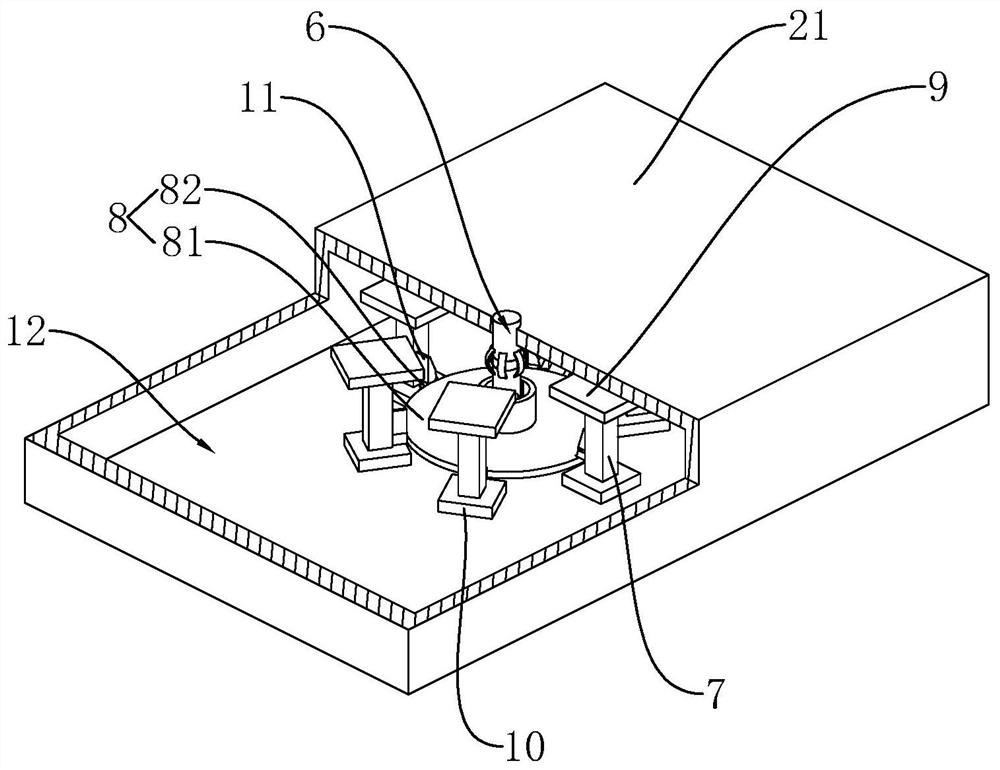

[0039] The following is attached Figure 1-4 The application is described in further detail.

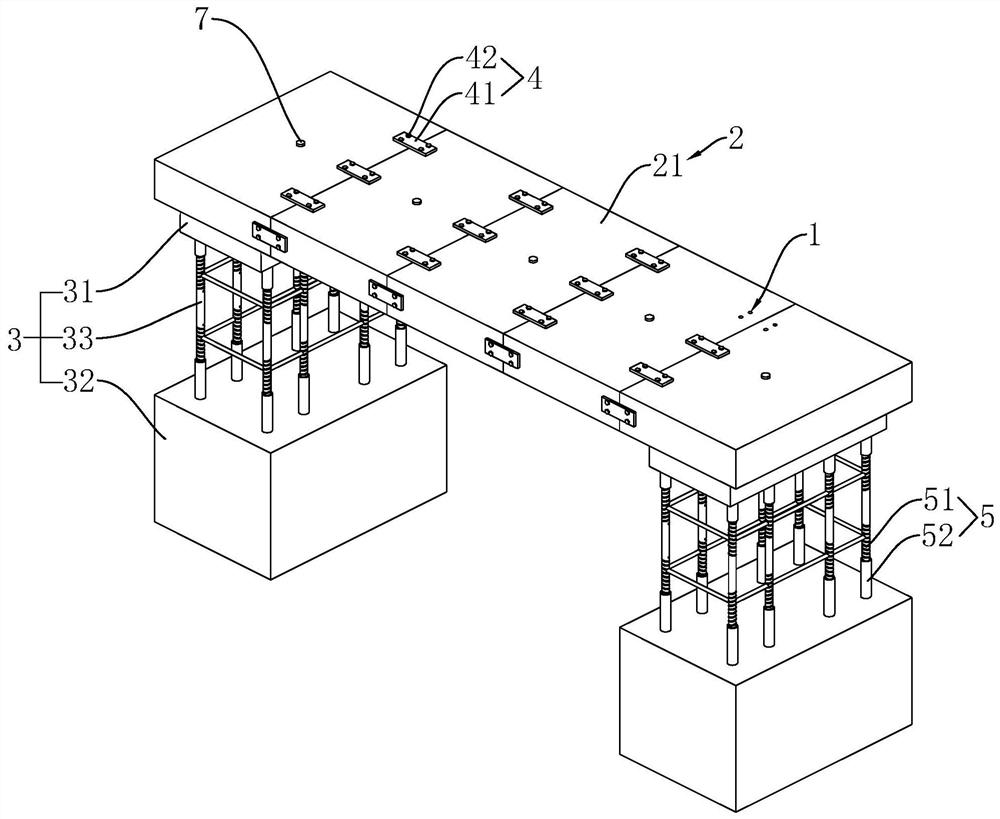

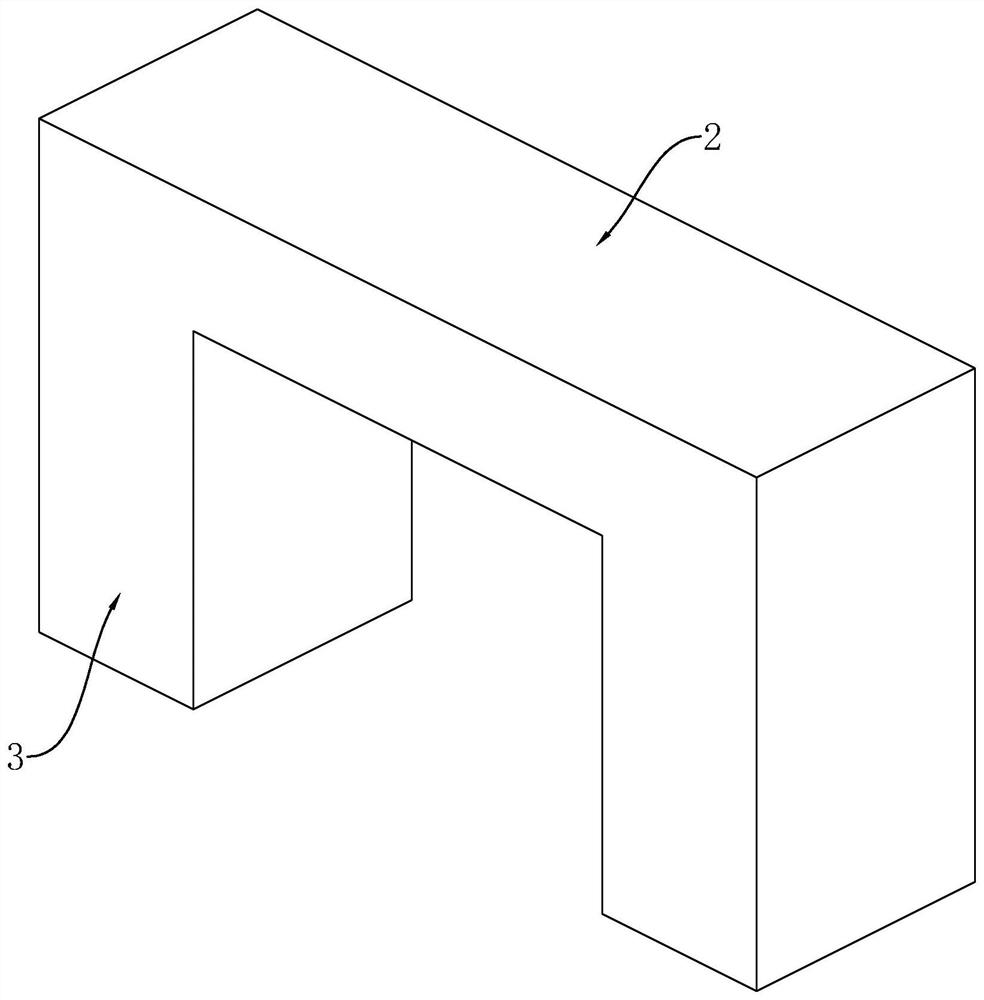

[0040] The embodiment of the present application discloses a highway culvert structure. refer to figure 1 and figure 2 , the highway culvert structure includes support beams 2 arranged horizontally. The two ends of the lower end surface of the supporting beam 2 are respectively vertically provided with supporting brackets 3, and meanwhile, both the supporting brackets 3 and the supporting beam 2 are reserved with threaded holes.

[0041] When building a culvert, the support beam 2 and the support corbel 3 are fixedly connected, and then the inner formwork and the outer formwork are fixedly connected to the support beam 2 and the support corbel 3 through bolts. Then pour concrete between the inner formwork and the outer formwork, and after the concrete is cooled and formed, the main body of the culvert can be obtained.

[0042] refer to figure 1 , the supporting beam 2 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com