Water conservancy construction safety facility

A technology for safety facilities and water conservancy, applied in the directions of roads, road signs, traffic signals, etc., can solve the problems of subsidence, soil density reduction, tilt, etc., to avoid the effect of removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

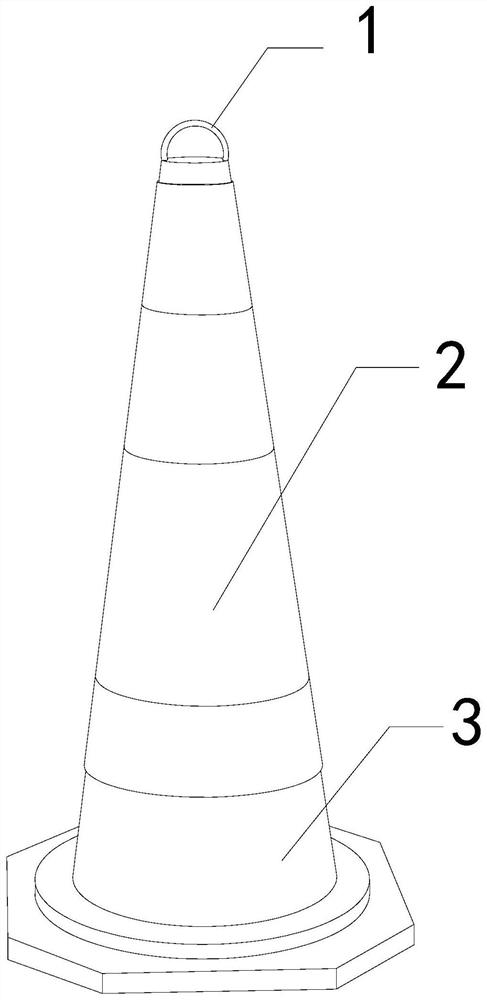

[0026]As for examplefigure 1 -exampleFigure 5 Shown:

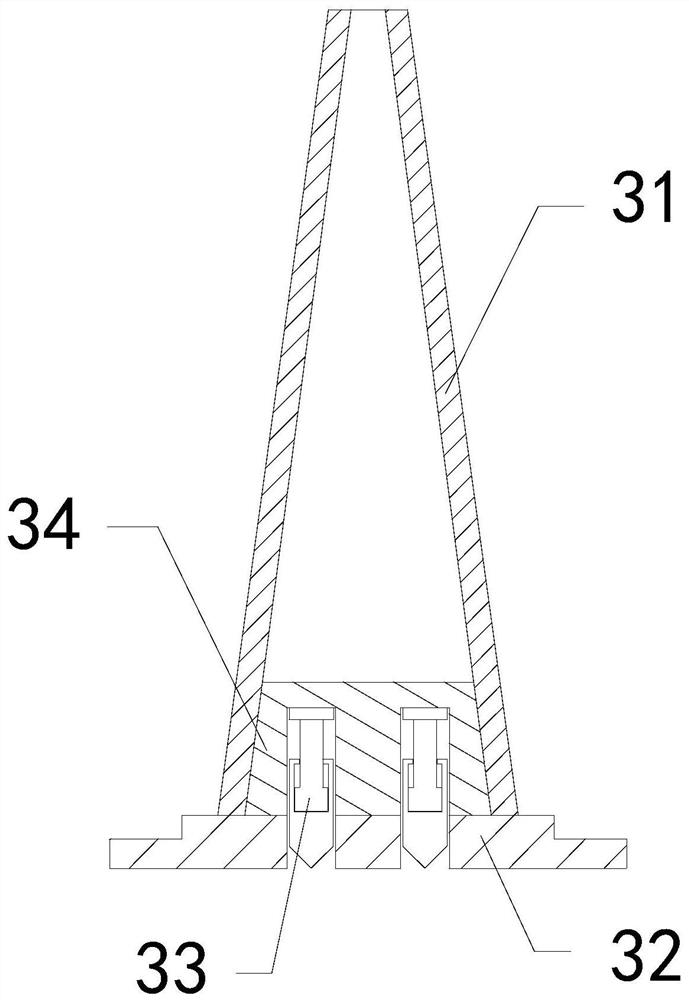

[0027]The present invention provides a safety facility for water conservancy construction. The structure includes a handle 1, a warning film 2, a bearing shell 3. The handle 1 is fixed at the upper end of the bearing shell 3, and the bearing shell 3 and the warning film 2 are Integrated structure; the carrying shell 3 includes an outer shell 31, a bottom plate 32, a sliding mechanism 33, an inner connecting plate 34, the bottom plate 32 is embedded in the bottom position of the shell 31, and the sliding mechanism 33 is installed at the inner position of the bottom plate 32 , The inner connecting plate 34 and the housing 31 are an integrated structure.

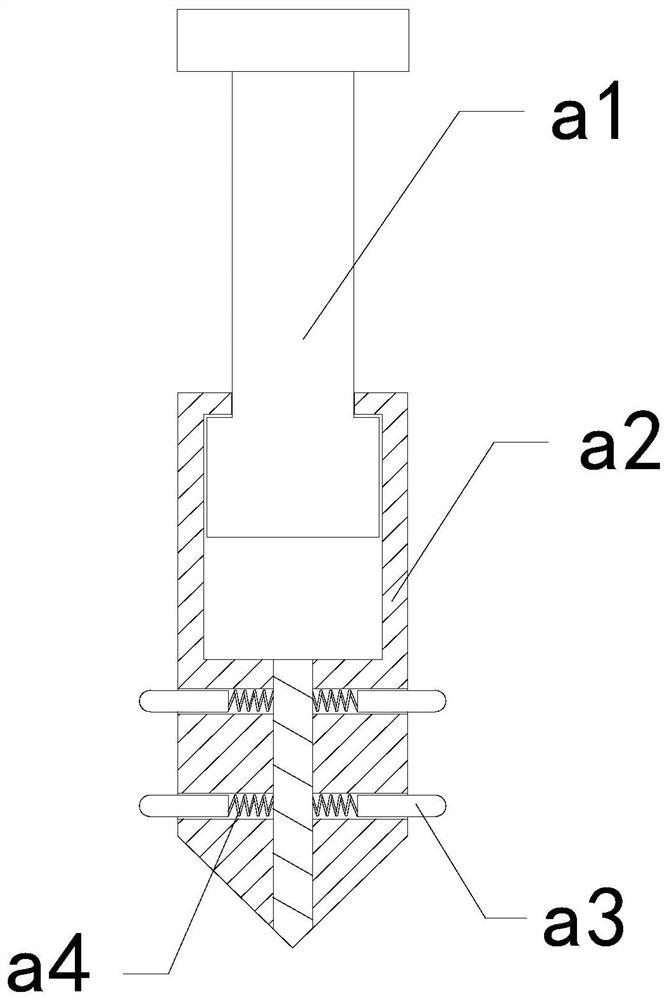

[0028]Wherein, the sliding mechanism 33 includes an engagement rod a1, an outer frame a2, an extension bar a3, and an elastic bar a4. The outer frame a2 is movably engaged with the engagement rod a1, and the extension bar a3 is in clearance fit with the outer frame a2. , The elastic st...

Embodiment 2

[0034]As for exampleFigure 6 -exampleFigure 8Shown:

[0035]Wherein, the grip increasing groove a35 includes a contact plate c1, a bottom plate c2, and a booster piece c3. The contact plate c1 is hingedly connected to the bottom plate c2, and the boost piece c3 is installed between the contact plate c1 and the bottom plate c2. At the same time, the vibration generated when the mechanism is contracted can make the contact plate c1 swing to the middle, so that the soil between the two contact plates c1 can be compacted.

[0036]Wherein, the contact plate c1 includes a water absorbing plate c11, an outer contact plate c12, and a receiving plate c13. The water absorbing plate c11 is movably engaged with the right side of the receiving plate c13, and the outer contact plate c12 is movably engaged with the right side of the water absorbing plate c11. For embedded connection, the water absorbing plate c11 is made of a corrosion-resistant and easy-to-clean polyether sponge material, and the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com