A plug-in strip for reducing copper loss

A technology of copper sheets and sockets, which is applied to parts of connecting devices, coupling devices, electrical components, etc., can solve problems such as poor contact, copper sheet wear, and metal fatigue, so as to prolong service life, reduce loss and damage, and improve structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

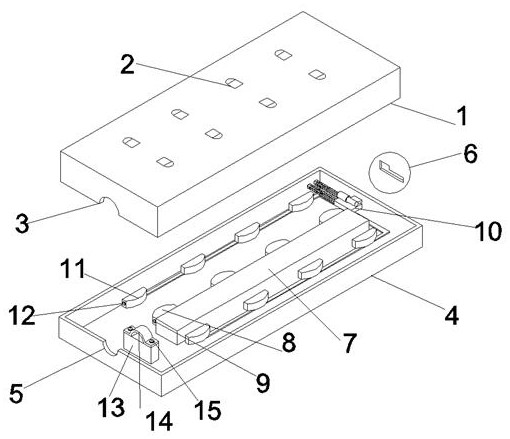

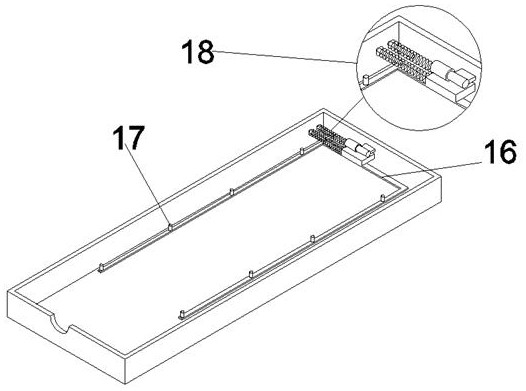

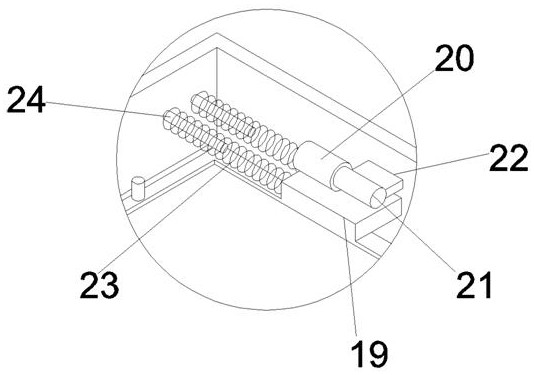

[0015] Such as Figure 1-3 As shown, a plug-in strip for reducing the loss of copper sheets includes a top cover 1, a socket 2, a top cover wire inlet 3, a base 4, a base wire inlet 5, a limit adjustment hole 6, a center bracket 7, and a live wire copper Sheet 8, live wire contact sheet 9, reciprocating limit device 10, zero line copper sheet 11, zero line contact sheet 12, branch line support table 13, branch line pressing sheet 14, pressing and fixing wire 15, the top cover 1 top A plurality of jacks 2 are provided equidistantly on the surface, and the top cover wire inlet hole 3 is opened at the center below the front of the top cover 1, and the base wire inlet hole 5 is opened at the center above the front of the base 4, and the limit adjustment The hole 6 is opened on the back of the base 4, the center bracket 7 is fixedly connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com