Aluminum alloy cladding material

一种包覆材、铝合金的技术,应用在金属加工、运输和包装、金属加工设备等方向,能够解决MgO皮膜生长、接合阻碍等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

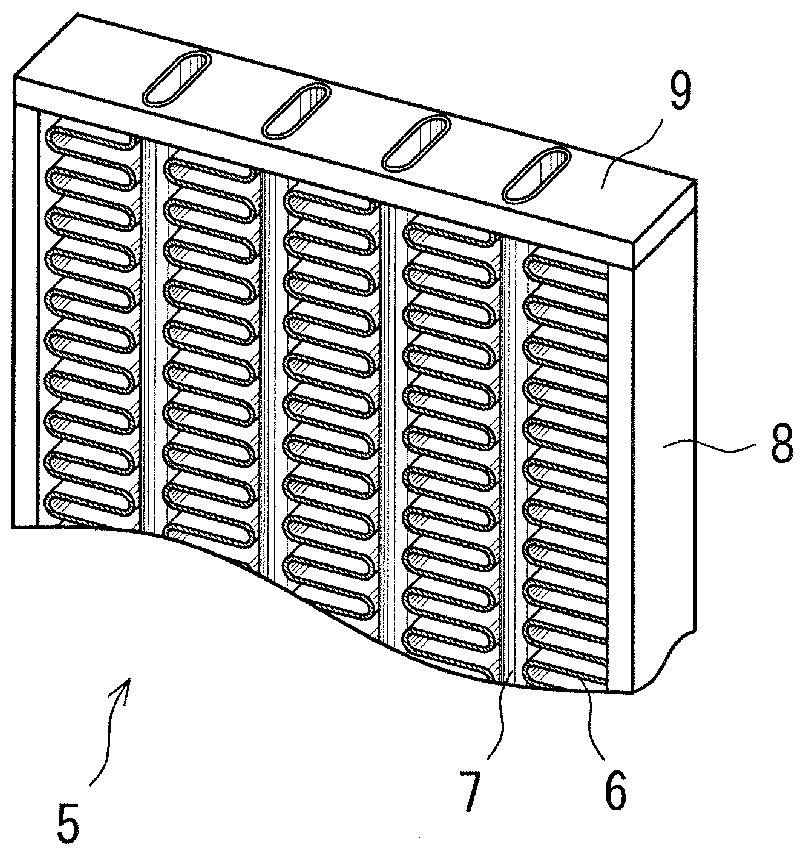

[0140] For various aluminum alloy cladding materials with the compositions shown in Tables 1 to 3 and Tables 5 to 7 (the balance is Al and unavoidable impurities), casting conditions and homogenization conditions shown in Table 9 ( Brazing material) and hot-rolled sheets were produced under hot-rolled conditions. In addition, "-" in a component shows that content is 0 or the amount of unavoidable impurity.

[0141] Then, by cold rolling including an intermediate annealing step, a cold-rolled sheet having a thickness of 0.30 mm in the H14 equivalent temper was fabricated. It should be noted that the covering ratio of each layer was 10% for the sacrificial material and 8% for the solder.

[0142] In addition, corrugated fins of JIS A3003 alloy and H14 aluminum bare material (thickness 0.06 mm) were prepared as brazing target members.

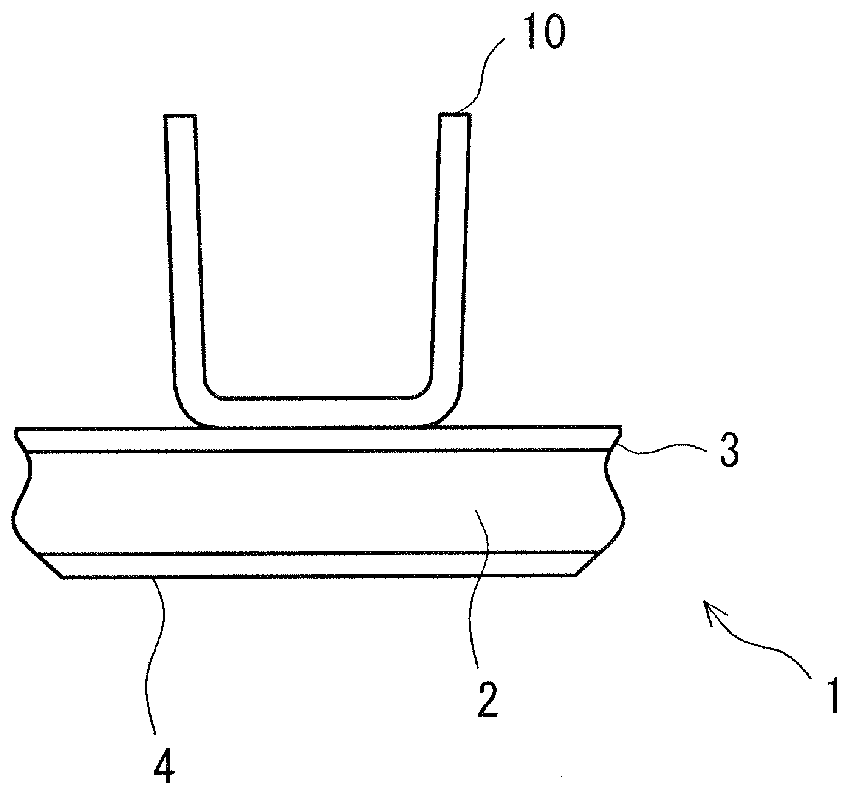

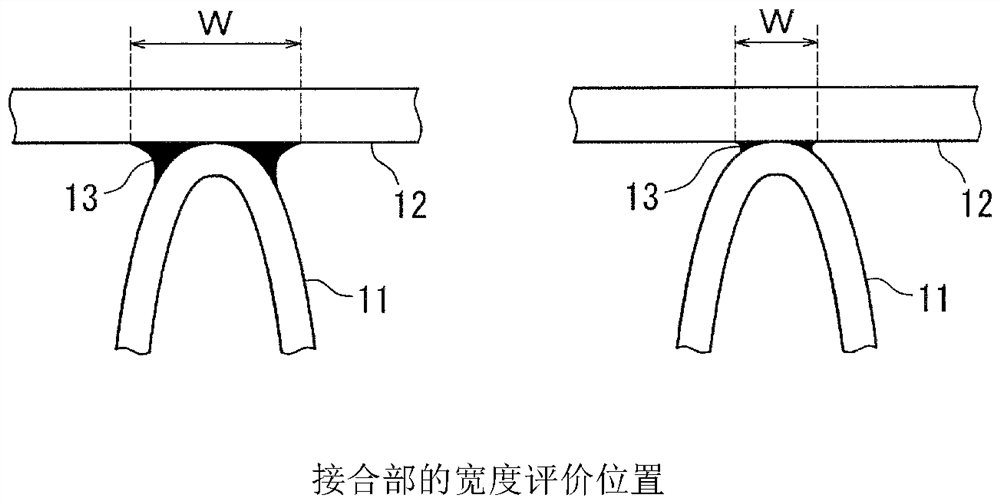

[0143] Use the aluminum alloy cladding material to make a tube with a width of 25 mm, and combine the tube and the corrugated fins to form the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com